Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

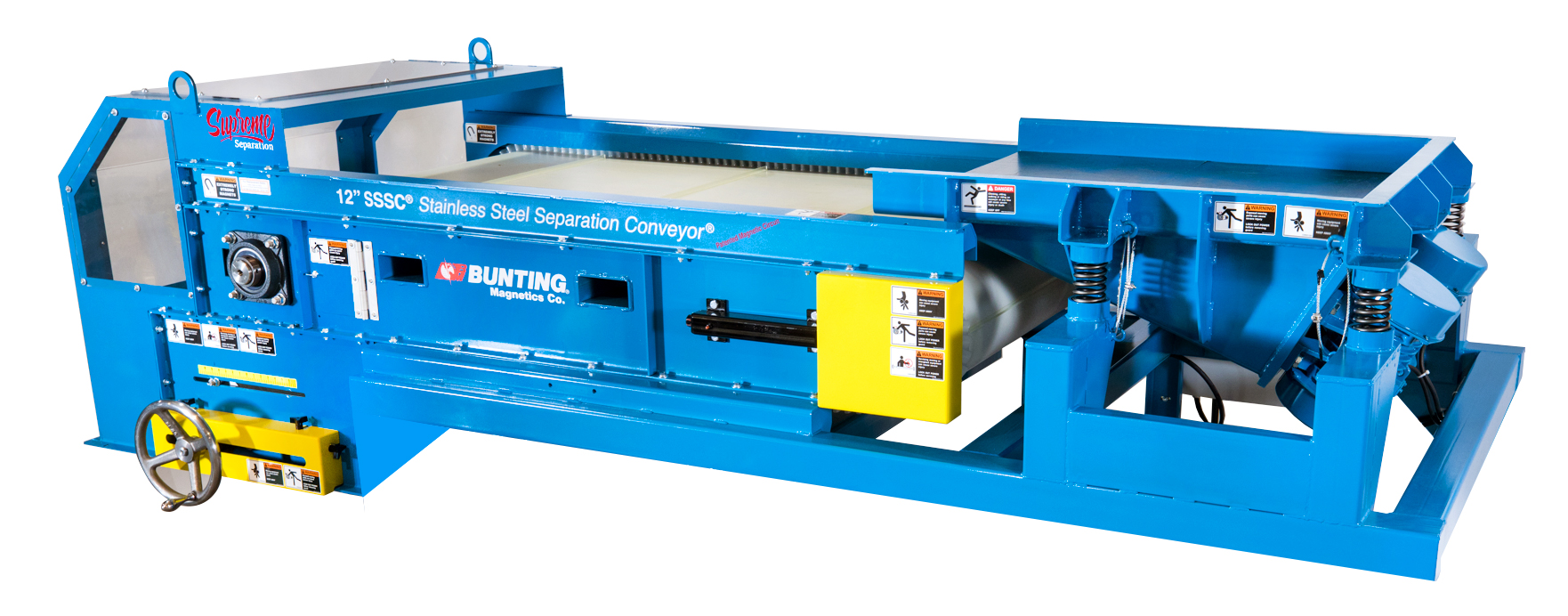

HISC® High Intensity Separation Conveyor®

HISC® High Intensity Separation Conveyor®

Magnetic Separation of Small Fraction Stainless Steel 5/8” minus and Wire-Cleaning Applications

Shredded Small Fraction SS ICW Insulated Copper Wire Chopped Copper Wire

Request a Quote

Applications

• ASR Zurik Stainless Steel Recovery and Purification

High Intensity Magnetic Fields pull out small fraction stainless steel from the finder streams, or recover from dirty Zurik lines to improve purity for higher profitability from domestic sales (estimated purity levels of up to 98% with optimum system).

• WEEE Waste Electronic and Electrical Equipment

Magnetically removing stainless steel and Green Boards from the product stream for recovery and purification.

• ICW Wire Separation / Wire Pre-Chopping Purification

For ICW wire-cleaning applications, it magnetically pulls out stainless steel and ferrous dirt pre-chop for less Chopper knife wear, higher throughput, less Chopper maintenance, less down time and higher profitability. Tests show total volume of stainless steel and ferrous dirt removed can be approximately 15% by weight.

• ICW Wire Separation / Wire Post-Chopping Purification

High Intensity Magnetic Field separation of chopped copper wire for

• Appliance Recycling Stainless Separation

Magnetically recovering lost stainless steel to improve profitability.

• Other Applications

Medical Stainless Steel Separation, Shredded or Ground Plastic Recycling purification, Pre-Eddy Current metal removal, Electronics Green Board and Hard Drive Recycling, rice – bean and dried vegetable purification.

Features:

• Available in 4” or 6” pulley diameter (6” for ICW wire lines and small fraction stainless steel).

• Standard widths run from 12” to 66” wide to match flow requirements.

• Neodymium High Intensity magnetic circuit.

• 2-ply urethane belt with 30mm flexwall and ½” sweeper cleats on 15” centers.

• 60-120 fpm variable speed with VFD depending on application.

• Heavy duty formed 3/16” sideguard with flexwall belt to seal off and contain flow.

• Heavy duty formed 3/16” frame construction with stainless steel frame and forklift lifting slots for installation.

• ¾ to 1½ hp 3ph 60hz single or three phase motors.

• 500-1,500 lbs per foot/per hour depending on application.

• Adjustable splitter to adjust for separation split and purity.

Optional Vibratory Feeder

• Provides uniform single-layer feeding for maximum separation efficiency – highly recommended.

• Common sub-frame for Vibratory Feeder and HISC to set in place – highly recommended.

• Customizable width and length to match applications.

• Comes complete with VFD controls and can be integrated into existing system.

Click here to download our brochure.

HISC® High Intensity Separation Conveyor® – Technical Specifications

YOU MAY ALSO BE INTERESTED IN:

|

|

|

|

|