Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

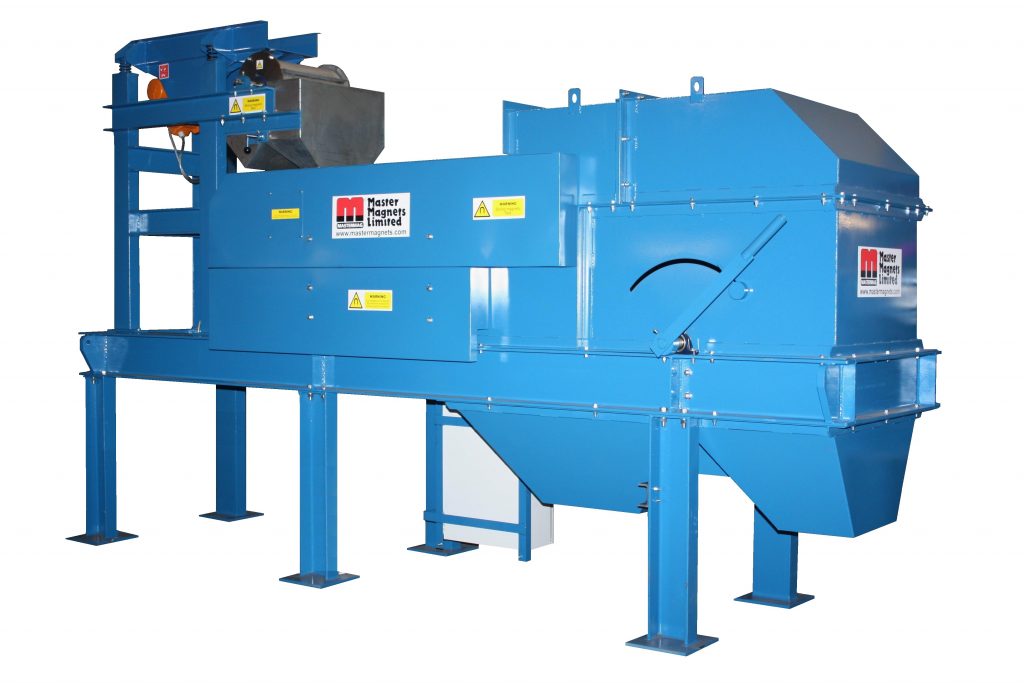

Heavy Duty Eddy Current Separator

Heavy Duty Separators for Advanced Metal Sorting

Bunting’s Heavy Duty Eddy Current Separator (ECS) is a highly advanced unit for sorting various non-ferrous metals. It uses Magnetic Finite Element Design to optimize the equipment’s magnetic field and maximize the focal point and strength of the equipment’s gauss intensity. The Eddy current separator separates non-ferrous conductive metal from non-conductive recycled materials. It is ideal for achieving maximum separation of small non-ferrous metals, such as aluminum chips, from crushed and ground materials. Through this engineering design and software technology, customers can achieve the cleanest materials possible.

Eddy Current Separator Operating Principles

The Eddy current separator starts with a short belt conveyor with a high speed magnetic rotor system installed at the discharge end and its drive located at the return end. The magnetic rotor is positioned within a separately rotating non-metallic drum. This magnetic rotor revolves at approximately 3000 rpm during operation. Meanwhile, the outer drum cover rotates at the same speed as the belt conveyor.

While the rotor spins at these exceptionally high speeds, it introduces an electric current into conducting metals. This electric current then produces a magnetic field, which goes on to oppose the field created by the rotor and repels conducting metals over a pre-positioned splitter plate. Any remaining materials will free-fall over the rotor, ensuring they are separated from the repelled metals.

Click to Request a Quote

Benefits of the Eddy Current Separator

• Designed to provide the optimal eddy current fields to achieve the maximum separation of small non-ferrous metals from other materials.

• Low maintenance conveyor with extremely tough urethane belts to allow longer wear.

• Cantilever frame weldment design allows easy slip off and on belt change within minutes.

• Double VFDs for optimizing relative belt speeds.

• Available in 24″, 36″, 48″ and 60″ widths with four rotor options available based on your application needs.

• Units can be designed into “custom systems” in combinations with equipment such as transfer conveyors into and out of the system, magnetic drum separation feeders, high intensity magnetic separation conveyors, magnetic crossbelt conveyors and vibratory feeder trays.

High Intensity Eddy Current Separator Units

High Intensity Eddy Current Separator Units utilize high repulsive forces to ensure the accurate separation of small, difficult to separate non-ferrous particles. This type of unit has a 11.8 inch diameter, 24 pole rotor and is available with operating widths of up to 6.5 feet.

Optional Extras

As part of the standard design, all Eddy current separator units are built with a vibratory feeder, chutes, covers and a base frame. Our Eddy current separator units are also supplied with a variable speed control panel, allowing for the rotor and belt speeds to be tailored to suit specific separation processes.

Other optional extras include:

• A high powered rare earth drum magnet to be utilized in applications with high ferrous content to remove small particles of ferrous materials, which may damage the rotor cover if caught underneath the belt.

• Rotary or static belt cleaning brushes for use in applications where the product may be wet or sticky.