Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

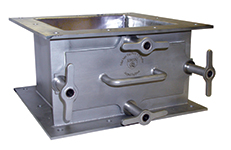

HF Drawer Magnets

Bunting HF Series Drawer Magnets

Bunting’s HF Series Drawer Magnets provide powerful magnetic separation suitable for mechanical and gravity flow applications in all industries. HF Series Drawer Magnets are equipped with high-power magnetic cartridges, configured with arrangements of two or more cartridge trays that are staggered to increase contact with the product stream. Material moves in a zig-zag pattern from one cartridge tray to the next, achieving exceptionally thorough cleaning as a result of intense magnetic separation. HF Series Drawer Magnets are available in utility, food, and sanitary constructions with multiple cleaning options and stainless steel housings. We are able to supply custom transitions to match your round, square, or rectangular spouting.

HF Series Drawer Magnets come standard with our NUHI™ Neo Ultra High Intensity Cartridge Magnet. These cartridges have been completely redesigned from the ground up in order to address new processing challenges manufacturers are taking. Bunting’s NUHI™ cartridge is nearly 20% stronger and delivers 50% more reach out than our previous cartridge design. This new design comes at no sacrifice to durability and quality—we are able to deliver improved power while maintaining our reputation for durable, long-lasting products that withstand the test of time. Our NUHI™ cartridge magnets amplify the performance of Bunting magnetic separation equipment, providing our customers with a higher standard of tramp metal removal.

Get a Custom Quote

Our HF Series Drawer Magnets are available in manual standard, manual self-cleaning, pneumatic self-cleaning, and pneumatic continuous self-cleaning models. All models are designed to facilitate effective removal of tramp metal contamination, including fines, while being easy to operate and maintain. HF Series Drawer Magnets come standard with two rows of NUHI™ cartridge magnets; with additional rows available for handling heavier product flow. They are constructed with heavy-duty 304 stainless steel, incorporating full-seam, air-tight welds. HF Series Drawer Magnets feature an easy access rear door for quick maintenance, and are available with inside dimensions of 8” x 8” to 24” x 24”. HF Series Drawer Magnets come standard with FDA-compliant metal detectable gaskets and grommets.

HFS Drawer Magnets – Technical Specifications

HF Series Drawer Magnet Features:

• Available in utility, food, and sanitary construction grades to suit your safety regulations, with multiple cleaning options and stainless steel housings.

• Bunting supplies custom transitions to match round, square, or rectangular spouting, allowing for a simple, secure fit with your existing equipment.

• Multiple trays provide increased contact with product flow for more complete metal capture.

• HF Drawer Magnets come standard with the NUHI™ Neo Ultra High Intensity Cartridge Magnet. Completely redesigned from the ground up to address the processing challenges manufacturers face, the NUHI™ cartridge is nearly 20% stronger and delivers 50% more reach out than our previous cartridge design. The result is more power, a purer product, and improved plant efficiency. Ceramic and rare earth magnets are also available.

• Heavy duty 304 stainless steel construction with full seam, air-tight welds.

• Easy access rear door for quick maintenance.

• Available with inside dimensions of 6” x 6” to 24” x 24”.

• Manual standard, manual self-cleaning, pneumatic self-cleaning, and pneumatic continuous self-cleaning configuration options are available.

• Come standard with FDA-compliant metal detectable gaskets and grommets.

• HF Drawers are rated at 10,000 gauss.

• Available with custom designs to accommodate hard to flow product

HF Series Drawer Configuration Options:

Manual Standard HF Drawer Magnet

In the manual standard configuration, ferrous debris is removed from the cartridges by sliding the trays out of the housing and wiping them off by hand. This allows for the operator to see exactly how much material was separated out of the product line, giving them insight into the process and providing hands-on interaction.

Get a Custom Quote

Manual Self-Cleaning HF Drawer Magnet

The self-cleaning configuration is designed to fully extend the magnetic cartridges outside the housing. As these tube assemblies travel outside the housing, grommets wipe the tubes clean all the way to their nonmagnetic tapered ends. This ensures that each cartridge is fully wiped and prevents captured tramp iron from re-entering the housings.

Get a Custom a Quote

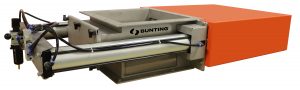

Pneumatic Self-Cleaning HF Drawer Magnet

The pneumatic self-cleaning configuration releases ferrous contaminants into the discharge area automatically using pneumatic power. With this model, product flow must be stopped in order to clean cartridges and prevent contaminated products from flowing into product stream. Pneumatic units operate at the touch of a remote switch or by a Bunting-engineered automated control package, making them an ideal choice for installing in hard-to-reach locations.

Get a Custom Quote

Pneumatic Continuous Self-Cleaning HF Drawer Magnet

The pneumatic continuous self-cleaning configuration utilizes a special drawer design that allows product to continuously flow while magnets are being cleaned. There is no need for a gate to stop product flow. Each row of magnets is cleaned in an alternating pattern, allowing the product to remain in contact with a row of magnets at all times. This unit operates by remote switch or by a Bunting-engineered automated control package, allowing it to be installed in hard-to-reach locations.

Get a Custom Quote