Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

Disc Separator

Bunting Magnetic Disc Separators for Mining, Aggregates and Minerals Industries

Disc separators are widely used to ensure accurate separation of materials that have varied magnetic susceptibilities. With their original design dating back to the early 1900s, they have a long history of usage in separation applications. Today, the disc separator has been updated to accommodate modern manufacturing demands and incorporate new innovations in technology.

Separation with High-Intensity Electromagnetic Discs

Separation with High-Intensity Electromagnetic Discs

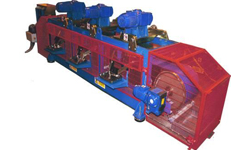

The standard design of a disc separator features up to three high-intensity electromagnetic discs, with each disc set at a different height from a feed conveyor. The first disc is positioned the furthest from the feed material, so as to extract only the particles that are most magnetically susceptible. The second and third discs are set at lower gaps, and by increasing the magnetic force at each disc, different grades of magnetic material are able to be effectively separated. To further adjust magnetic intensity, the current of the coil can be adjusted to suit specific mineral separation requirements. This feature means that each disc separator can be set up and designed for an individual mineral ore.

In operation, processing begins with a hopper dispensing feed material onto a vibratory feeder tray, which then distributes material onto a thin and even layer onto a moving conveyor. While material is being conveyed beneath the rotating electromagnetic discs, the high gradient magnetic zones on the discs attract magnetic particles. Next, the rotating discs carry these captured particles to discharge chutes, entering a non-magnetic area where material is then released. To ensure total discharge of magnetic particles, scrapers are mounted on the chutes. Any non-magnetic material then moves to the second magnetic separation zone, undergoing secondary separation before finally being discharged as a clean non-magnetic product. If necessary, a third stage of separation may be added.

Click to Request a Quote

Typical Applications:

–Beach sands (separating ilmenite, garnet, monazite, and zircon sand)

–Tin processing

–Wolframite recovery

–Abrasive minerals separation

–Tantalite and Columbite separation

Magnetic Disc Separator Features:

• Material is continuously transported beneath rotating discs where magnetic particles are attracted to the high gradient magnetic zones on the disc. Powerful magnets allow for strong attraction of contaminant particles and ensure they are held securely to the disc before being released at the discharge chute.

• Scrapers mounted on chutes ensure the total discharge of magnetic particles.

• Two zones of magnetic separation to ensure all contaminants are removed. • Physical action of separator lifting magnetic minerals from the conveyor belt results in very clean magnetic fraction.