Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

Recycling

Material Handling, Magnetic Separation, and Metal Detection Equipment for the Recycling Industry

Recycling is an industry that can take on many forms, and in today’s climate, all forms of recycling are in high demand. Whether you are recycling plastic or glass, whether you work in an auto shredding or municipal facility, whether you are handling stainless steel or insulated copper wire—Bunting can provide recycling equipment solutions for your unique recycling application to purify your product or to protect your equipment. We seek to be a “one-stop source” for recycling equipment, and we are an innovative, complete resource for magnetic separation, metal detection, and material handling products. At Bunting, we provide comprehensive solutions that emphasize safety, accuracy, and efficiency. We pride ourselves on working closely with customers to develop custom equipment that fits their needs perfectly. This allows our product to integrate seamlessly with the existing components of the recycling environment, as well as providing the best suited equipment for handling the material the customer is working with.

Request a Quote for Your Recycling Facility

Bunting® is a One-stop Source for Recycling Equipment used in Material Recovery Facilities

Bunting provides equipment to help customers working in the recycling industries by using magnetic separation technology to remove metal contaminants from material streams, providing metal detection equipment to alert operators of ferrous and non-ferrous metal hazards within the product flow, and removing or rejecting that contamination for a purer product stream. All of our equipment is designed to be low-maintenance and operator friendly to increase efficiency and decrease downtime in your operations.

Magnetic Separation for Recycling

Magnetic separation utilizes powerful magnets to pull out ferrous metal contaminants from a processing line, trapping them against the face of the magnet and ensuring they cannot re-enter the material stream. The strength of the magnetic field means that continued material flow, no matter how rapid, will not be able to dislodge the ferrous material from where it has been initially trapped. Bunting offers magnetic separation equipment suitable for gravity free-fall systems, in-line systems, and liquid processing systems.

Metal detection for Recycling

Metal detection systems generate an electromagnetic field that material flows through, sensing and rejecting any ferrous or non-ferrous metal that is hidden within the material. In situations where a magnetic separator may be unable to remove a non-ferrous contaminant, such as aluminum, a metal detector is able to sense this metal and remove the contaminated section of material from the greater flow of operations. Bunting offers metal detection equipment suitable for gravity free-fall, pneumatic, and all conveyor applications, with three different packages available for electronics customization.

Bunting offers conveyor systems and conveyor system components in order to provide efficient transport of various recycled materials throughout your facility. Bunting’s wide line of conveyors and accessory parts offer an efficient, low-maintenance answer to moving high volumes of material quickly and safely in any environment, no matter how tough. From feeding material into shredders with magnetic and metal detection separation capabilities, transferring that shredded material to a granulator or to a high intensity magnetic separator over a vibratory feed feeding an Eddy Current or Drum Separator, Bunting has the complete line.

All of our products are custom designed by our engineers according to the customer’s specifications, allowing for them to integrate seamlessly into the existing production environment. Our team of engineers work with each customer to deliver a personalized piece of equipment with the physical dimensions to best fit your space and flow stream, and with the magnetic components that best suit your separation, detection, and conveying needs.

Electromagnetic Dry Filter

Industry: Recycling, Battery, Mineral

Strength: 3,500 & 5,000 Gauss (background field)

Magnet: Electromagnet

Material: Dry Fine PowdersElectromagnetic Wet Filter

Industry: Ceramics, Battery, Recycling, Mineral Processing

Strength: Up to 10,000 Gauss (background field)

Magnet: Electromagnet

Material: Slurries and LiquidsFF Series Drawer Magnets

FF Series Drawer Magnets are built with strong Rare Earth magnets for strong holding force in gravity flow applications. They are temperature compensated with stainless steel construction and designed for the Plastics Industry.

In-Line Magnets

In-Line Magnets are for Gravity or Pneumatic flow applications. Enclosed pipe systems for unobstructed product flow. Rare Earth Magnets are standard. For all industries.

Plate Magnets

Plate Magnets capture fine metal particles from chutes, suspended in powdery, moist, clumpy, abrasive or bulk materials. Various models available. For all industries including, Food, Powder & Bulk, Grain & Milling, Recycling and Plastics.

Permanent Drum Magnets

Permanent drum magnets are versatile, robust magnetic separators that are well suited to a wide range of applications, including those in the food, plastics, powder and bulk, grain and milling, and metal recycling industries.

Electro Drum Magnets

These heavy-duty magnetic separators are designed to separate and recover large pieces of ferrous tramp metal out of the product stream.

Drum Magnet

Drum Magnet Separators come in 3 grades of Rare Earth Magnets and are self-cleaning. They provide continuous removal of ferrous contaminants from product flow.

Air-Cooled ElectroMax Suspension Magnet

Bunting’s Air-Cooled ElectroMax Suspension Magnet removes ferrous material in burden depth up to 25”, depending on material.

High-Intensity Eddy Current Separator

The application of Eddy Current Separators in the recycling sector involves the retrieval or exclusion of non-ferrous metals from materials that lack metallic properties.

Gravity Free-Fall Style Metal Separators – Recycling and Plastics

Automatically detects all ferrous and non-ferrous metals without process interruptions by separating contaminated materials from product flow.

Pneumatic Style Metal Separators

These metal separators detect and reject all metal types in enclosed pipe systems. Easy operation, fast-acting reject flap, and maintenance-free.

Cleaning Systems

Cleaning systems use magnetic and electronic separators to remove both ferrous and nonferrous contaminants efficiently from free-flowing virgin resins, regrind, and recycled plastics.

SSSC® Stainless Steel Separation Conveyor™

Separate irregular shaped paramagnetic work-hardened stainless steel – up to 5″ in size – from your recycled materials or in copper wire application.

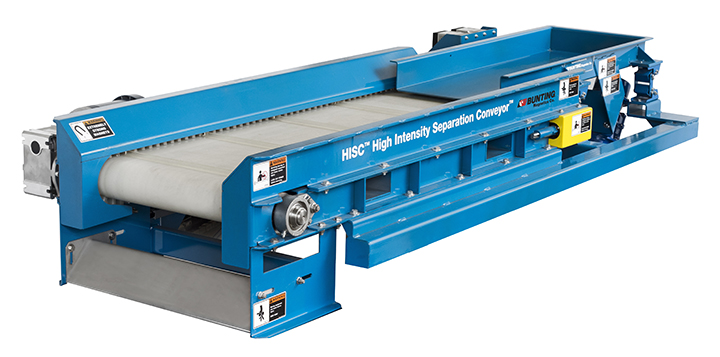

HISC® High Intensity Separation Conveyor®

Designed for extreme high gauss fields of magnetic separation of work hardened stainless steels and removal of lightly magnetic tramp metal fines.

Eddy Current Separator

The Eddy Current Separator core is designed to provide a high level of gauss intensity to enhance separation on a wide range of nonferrous conductive materials and sizes. It is protected with the tough urethane belt and a fiber shell. From aluminum cans to aluminum flakes, our ECS units do an excellent job of throw and separation.

Crossbelt Magnetic Separators for Recycling

Continuous over-conveyor separation for the recycling industry to remove ferrous materials from non-ferrous materials in plastics, wood, tire, metal and municipal scrap recycling.

Electro Crossbelt Magnetic Separators

The most powerful crossbelt separators available from Bunting’s current range of products. A wide range of sizes are available for this type of separator, ensuring you will be able to find an option that meets your needs.

Shredder Feeder & Discharge Conveyors

Grinder Feeder Conveyors can be used to protect your Shredder from being damaged by separating out the metal contaminant with a magnetic cross-belt or metal detector before the product is transferred to a shredder, and Discharge Conveyors can purify your product on the way out.

DragSlide Conveyors

DragSlide conveyors are totally enclosed and use UHMW drag flights in a chain conveyor design to move and convey film & fiber materials within a sealed conveyor. This makes for a much cleaner facility allowing you to use your employees for production versus clean-up maintenance.

Bale Inspection Conveyors

Bale Inspection Conveyors with metal detectors provide inspection for baled recycled materials. Can be used as either a stand-alone conveyor or as an in-feed conveyor to the shredder line.

Bale Break Conveyors

Bale Break Conveyors break up bales of recycled plastic bottle containers. Heavy-duty construction for rigorous applications. Designed to improve loading and separations efficiency with recycled materials.

Sorting Table Conveyors

Most commonly used in the Municipal Recycling Industry, this Sorting Table Conveyor is built with short sideguards and UHMW skirting for safety. Complete with elevated working mezzanines, stairs, drop chutes and belly rests for the operator’s comfort.

Trough-Belted and Transfer Conveyors

Horizontal and inclined regrind or pellet transfer conveyors in any size your application requires. Various belt styles including smooth flat flexed wall, cleated or cleat topped belted conveyors to transfer bulk material to a Granulator or storage facility.

Magnetic Pull Test Kits

These test kits has been developed for the purpose of field inspection, measurement and performance analysis of permanent magnetic separation equipment to guard against a lapse in magnetic protection.

Gaylord Cleaning Station

The Gaylord Cleaning Station combines a Bunting drawer magnet with an electronic metal detector to remove ferrous and nonferrous contaminants.

Metal Detectors for Conveyors – Recycling and Plastics

Our metal detection equipment works in conjunction with our conveyors to protect your product and equipment from damage. For under-the-belt and over-the-belt conveying for product inspection.

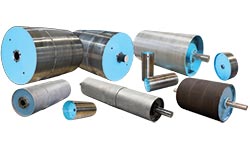

Magnetic Pulleys

Offering superior continuous removal and discharging of ferrous contamination like nails, staples, bolts, and wire from conveyors, all with maintenance free operation.

Metal Detector Test Standards

They are an easy and economical way to maintain consistent operation and product quality. We offer precision test blocks and ball bearings for metal detector calibration and performance checks.

Heavy Duty Drum Magnets

The Magnetic Drum Separator is normally installed at product discharge points and incorporates a 150 – 180 degree magnet system, encased in a stainless steel shell, or manganese wear plates for severe application.