Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

Shredder Feeder & Discharge Conveyors

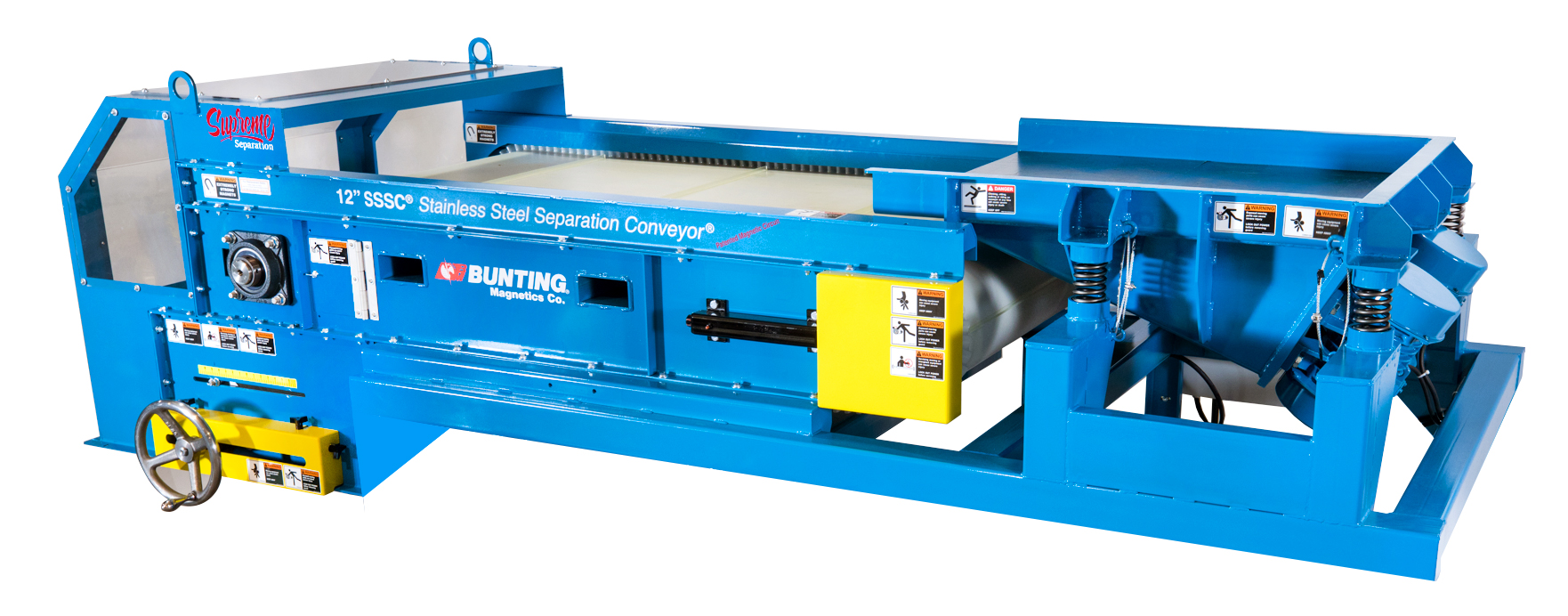

Shredder Feeder & Discharge Conveyors with Magnetic Separation for Purified Recycling, Shredding & Grinding

We have the expertise to provide you with all the conveyor, metal detection, and magnetic separation equipment to layout your shredding system. Whether you are re-grinding in-house scrap product or designing a complete recycling facility, we have feeder conveyors and discharge conveyors to handle your material on both ends of the shredding process.

By enhancing your conveyor system with specially-designed Conveyor Metal Detectors or an Overhead Magnetic Crossbelt, you can:

By enhancing your conveyor system with specially-designed Conveyor Metal Detectors or an Overhead Magnetic Crossbelt, you can:

1. Protect your shredder by inspecting all of your product and scrap before it is fed into the shredder. That not only protects your shredder from being damaged but also separates out the metal contaminant before it is shredded into smaller pieces. Product purification is maximized.

2. Maximize product purity upon shredding discharge, before feeding material to a Granulator or Extruder. This not only protects your Granulator but also separates out the metal contaminant before using or selling the regrind.

We can help you select and combine the proper equipment to optimize the purification of your product, maximize your equipment protection and protect your investment from serious damage and repairs. Each of the following units can be custom painted to match your shredder.

Enhance your Shredding Operation with Bunting® Equipment

Feeder Conveyors for Shredders & Grinders

Heavy-Duty GFC Conveyors

• Handles between 8,000 to 20,000 pounds of product per hour.

• Constructed of 12″ to 15″ channel iron.

• 4-ply belts with heavy duty cleats.

• UHMW skirting to protect belt edges.

• Uses 10″ to 12″ pulleys with large drives.

• Optional metal detectors as large as needed for whole bale inspection.

Standard-Duty GFC Conveyors

• Used for shredding and grinding up plastic purgings to scrap bumpers, stringers, carpet, wood pellets, plastic bottles, tires or even glass bottles or wood pallets.

• Handles between 1,000 to 10,000 pounds per hour.

• Formed steel frame construction.

• Uses 6″ to 10″ pulleys.

• Multiple belt options with standard cleats or cleat topped belts.

• UHMW, formed metal or rubber skirting.

• Optional metal detectors with flip gate reject of contaminant.

• Optional infeed hoppers, magnetic pulleys and mobile bases.

Light-Duty GFC Conveyors

• For in-house use next to the machine grinders.

• For low volume applications that are usually hand fed.

• Constructed of a fabricated steel frame, smaller drives, and 3″ to 6″ pulleys with an inexpensive cleated or ruff-topped belts.

• Optional over the belt plate magnet or under the belt meTRON™ S 05 metal detector.

Shredder/Grinder Feeder Conveyor Optional Accessories:

• Small or large In-feed Hoppers

• Single or dual sided Sorting Table Conveyors

• Work Mezzanines

• Bale Break Stations

Shredder Discharge Conveyors

Heavy-Duty GFC Hockey Stick Conveyor

• Designed for flow rate of 8,000 to 20,000 pounds of product per hour.

• Constructed of formed steel or channel iron frames.

• Built for the most rugged applications.

• Heavy cross-rigid cleated or cleat top belt.

• UHMW skirting or formed metal.

• Flared in-feed hoppers to match up to Shredder discharge openings.

• Uses 10″ to 12″ pulleys with large drives.

• Optional accessories include magnetic crossbelt separator, magnetic head pulley or meTRON™ D 05 metal detector with flip gate rejects of contaminant.

Standard-Duty GFC Hockey Stick Conveyors

• Formed steel frame construction.

• Uses 6″ to 10″ diameter pulleys with optional magnetic pulley.

• Heavy cleated cross-rigid flex wall belts.

• Flared in-feed hoppers to match shredder discharge openings.

• Optional under the belt or loop style metal detectors.

• Optional flip gate of contaminant, and mobile bases.

• Can be used as direct transfer of material from shredder to grinder.

Shredder/Grinder Discharge Conveyor Optional Accessories:

• Magnetic Crossbelts

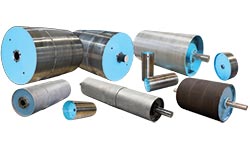

• Ceramic and Rare Earth Magnetic Head Pulleys

• Rare Earth Plate Magnets mounted above the belts

• Metal Detectors with and without automatic contaminate reject flip gates

• Sacker stations for shredded and ground material

GFC Conveyor – Technical Specifications

Enhance your Shredding Operation with Bunting® Equipment

Application or Quotation Assistance

Please call 1.800.835.2526 or 316.284.2020 and ask for extension #142 or #146 to discuss your needs with an Inside Sales Design Associate or to get an Application Engineer to visit your facility. We can also email you a RFQ form that you can quickly fill out to get a quotae.

YOU MAY ALSO BE INTERESTED IN:

|

|

|

|

|