Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

Printing Products

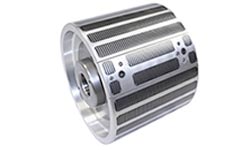

World Leader in the Manufacture of Magnetic Printing Cylinders

Bunting® provides unmatched quality, superior service, accurate, and unique to meet your demands in the printing industry. We specialize in magnetic printing cylinders, die-cutting cylinders, can decorating products, and more.

Most Accurate in the World

Bunting is recognized as the world’s leading manufacturer of magnetic die-cutting cylinders. Our magnetic cylinders hold the tightest tolerances in the industry. We have invested in state-of-the-art precision machinery to manufacture our magnetic cylinders to meet or exceed OEM specifications.

Groundbreaking

Our patented Cerface™ magnet circuitry design features higher quality magnets and better bonding of the magnets within the cylinder.

Unique

We have developed special techniques for the grinding process of our magnetic printing cylinders. This allows us to hold tighter tolerances than competitive cylinders. In fact, the runout tolerances on our X-treme® Series cylinders are so precise, many competitors do not have the tools necessary to measure them.

The bottom line is that we have state-of-the-art equipment and the most innovative manufacturing techniques in the industry. These capabilities allow us to make the most respected magnetic cylinders in the world while providing our customers quick turnaround to meet your needs.

Meets Close-Tolerance Demands

Our tight tolerance magnetic printing cylinders greatly reduce the time typically required for set-ups. Machined to run out tolerances of just 1 micron and finished with a grinding process unmatched by anyone in the industry, these cylinders stand the test of time.

Repair & Inspection

Comprehensive inspection and repair service on many magnetic cylinders, anvil cylinders and stamping bases.

Request a Quote for Your Magnetic Printing Applications

ANC Rexam Megyesi Cylinder and Shaft

After Rexam purchased ANC at the beginning of the new millennium, some of the 22 US-based and 13 Europe-based plants continued using the ANC/Rexam tapered shaft and cylinder design.

Cone Cylinder and Shaft Assembly

Starting in 2023, a new Bunting facility known as the “Manufacturing Center for Magnetic Decorator Cylinders” will be equipped to produce CONE-style tapered shafts and tapered bore cylinders.

Plastic Container

We also manufacture cylinders to be used on plastic containers. Many OEMs utilize Magnetic print cylinders in their equipment to print cups, pails, buckets and caps.

PlateMaster™ Printing Cylinder Assembly

Perfect for today’s high definition print jobs and 2-piece can decorating. The patented PlateMaster™ offers a combined shaft and cylinder runout of less than 7/10,000th of an inch.

2-Piece Can Decorators

Dry Offset Cylinders offer fixed or patented adjustable pin options to reduce costs. Features include light weight, sleeved, multiple registration, and application specific designs to ensure quick plate changeovers.

Folding Carton

Two Bunting® Magnetic Die-Cutting Cylinders can convert your narrow web press for folding carton and other die-cut production. These cylinders give you quick changeovers and guaranteed fit.

Label & Narrow Web

Magnetic Die-Cutting Cylinders use magnets to hold flexible dies in place. Variations include standard tolerance, x-treme precision tolerance and folding carton.

Corrugated Board

The Magnetic Corrugated Cylinder allows you to finish more jobs per day using metal-backed plates on your flexo-folder gluer or flexo-printer die cutter. Optional Matthews Fast Lock available.

Special Order Cylinders

Depending on your application needs, Special Order Cylinders can be customized for non-standard dimensions, outfitted with special bearers, or equipped with high-energy Neodymium magnets.

Flat Bases for Stamping

Magnetic Stamping with flat bases are for Platen and Flatbed Printing and Die Cutting. Magnetic Hot Stamping Bases are for foil stamping. They can be used for automatic and semi-automatic processes.

Cylinder Accessories

Accessories for Cylinders include Plate Formers, Web Protection Magnets, and Corner Rounders. Used to protect cylinders, enhance plate performance, and make operations safer.