Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

Grain & Milling

Bunting: Superior Removal of Metals for the Grain and Milling Industry

Bunting® Since 1979, Bunting’s company headquarters have been located in Newton, KS. We are a global company, with locations throughout the United States, the United Kingdom, and the rest of the world, but since our headquarters are located in the heart of America’s breadbasket, we find ourselves especially close to the grain and milling industries that are of such great importance to this region—and the world. Grain and milling industries nourish the world with essential crops such as wheat, corn, barley, and more. Because these products are so essential, they must be free of harmful metal contamination for the safety of consumers as well as to protect the other manufacturing equipment in a grain and milling facility.

Request a Quote for Your Grain & Milling Facility

Separation technology that protects equipment and reduces metal contamination.

When crops are harvested, there are many points of entry for metal contamination to enter the product stream. Metal contamination can take many forms, ranging from a broken piece of harvesting equipment, to a screw, or a tiny metal shaving. This is of great concern, as even the smallest metal shaving can have devastating consequences if it is allowed to travel undetected in a processing line and go on to cause damage to other equipment, such as roller or hammer mills.

To combat metal contamination in the grain and milling industries, Bunting offers a wide range of magnetic separation and metal detection products. Our powerful magnetic separation equipment is able to capture and hold even the smallest of ferrous tramp metal, protecting your product purity as well as your equipment. Our metal detection equipment detects and rejects all ferrous metal, non-ferrous metal, and stainless-steel metal contamination in your product flow. Additionally, Bunting offers an extensive catalog of material handling conveyors to assist you in efficiently transporting product throughout your facility.

At Bunting, we are committed to serving our customers in the grain and milling industries and seek to provide them with efficient, dependable magnetic separation and metal detection equipment. We are proud members of GEAPS and showcase and support IAOM chapters throughout the country. Bunting is proud to play a part in helping those in the grain and milling industries provide their customers with safe, high-quality products.

Now is a GREAT TIME to update your CRITICAL EQUIPMENT and SPARE PARTS. Successful detection and separation of metal will protect your processing equipment from damage, which saves your organization money and downtime.

Click to View a Grain and Milling Perfect Plant diagram.

HF Drawer Magnets

HF Drawer Magnets are for gravity flow applications. They house two or more magnetic cartridges for efficient product separation. For all industries – Food, Grain and Milling, Powder and Bulk, Recycling, and Plastics.

In-Line Magnets

In-Line Magnets are for Gravity or Pneumatic flow applications. Enclosed pipe systems for unobstructed product flow. Rare Earth Magnets are standard. For all industries.

Magnetic Cartridges & Grate Magnets

Grate Magnets and Magnetic Cartridges are engineered to achieve balance between reach-out and holding force. Can be used in all industries.

Plate Magnets

Plate Magnets capture fine metal particles from chutes, suspended in powdery, moist, clumpy, abrasive or bulk materials. Various models available. For all industries including, Food, Powder & Bulk, Grain & Milling, Recycling and Plastics.

Permanent Drum Magnets

Permanent drum magnets are versatile, robust magnetic separators that are well suited to a wide range of applications, including those in the food, plastics, powder and bulk, grain and milling, and metal recycling industries.

Drum Magnet

Drum Magnet Separators come in 3 grades of Rare Earth Magnets and are self-cleaning. They provide continuous removal of ferrous contaminants from product flow.

TurboGrate™ Magnetic Separator

TurboGrate™ Magnetic Separator features a powerful motorized rotating grate magnet to remove ferrous metals from powder and granular materials. For the Food and Powder & Bulk Industries.

meTRON™ 07 CI Metal Detector with Bulk Sense Kit

Accurately detects metal in 50lb-100lb bags of dry product such as large bags of flour, powder, and other dry bulk products.

Pneumatic Style Metal Separators

These metal separators detect and reject all metal types in enclosed pipe systems. Easy operation, fast-acting reject flap, and maintenance-free.

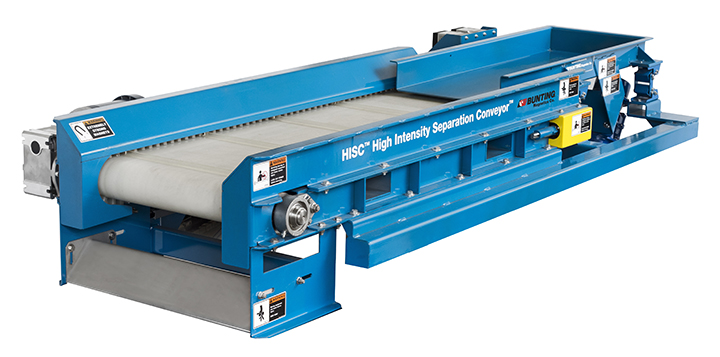

HISC® High Intensity Separation Conveyor®

Designed for extreme high gauss fields of magnetic separation of work hardened stainless steels and removal of lightly magnetic tramp metal fines.

Hump Magnets

Hump Magnets are for high-volume product flow. Offset design breaks up clumps and directs material into magnetic field. Self-cleaning model available. For all industries.

Magnetic Pull Test Kits

These test kits has been developed for the purpose of field inspection, measurement and performance analysis of permanent magnetic separation equipment to guard against a lapse in magnetic protection.

Tunnel Style Metal Detectors with Conveyors

Tunnel style metal detectors can be used to inspect raw foods or for final inspection in a packaging line, to make sure their is no metal in the product before shipping to the customer.

Gravity Free-Fall Metal Separators – Food, Powder & Bulk

Automatically detects and rejects ferrous and nonferrous contaminants from product flow, safely and efficiently.

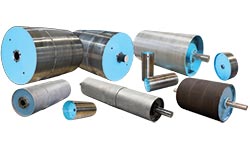

Magnetic Pulleys

Offering superior continuous removal and discharging of ferrous contamination like nails, staples, bolts, and wire from conveyors, all with maintenance free operation.

Wedge Magnets

Wedge Magnets are designed for narrow chutes and protect against tramp metal damage for pellet mills. Shape diverts product flow across collection surfaces. For all industries.

Metal Detector Test Standards

They are an easy and economical way to maintain consistent operation and product quality. We offer precision test blocks and ball bearings for metal detector calibration and performance checks.