Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

Plastics

Bunting® is The Leader for Metal Detection in Plastics.

For over 60 years, Bunting has been a leading supplier of high-quality magnetic separation, metal detection, and material handling equipment for customers working in the many different facets of the plastics industry. Additionally, we supply the plastics industry with top-of-the-line magnetic printing cylinders for plastic decoration. Bunting’s wide variety of magnetic separation and metal detection products help you to protect your equipment from the costly repairs associated with metal contamination. If metal contamination is allowed to persist in material, severe damage can occur to expensive specialty equipment such as blow molding, injection molding, extrusion, and compounding machines.

Request a Quote

Magnetic Separation for diverse applications within the Plastics industry.

Bunting pioneered the industry standard FF Magnetic Separation Drawer for the plastics industry, and today we offer the greatest range of options for metal removal. No other company has the variety that Bunting does. Bunting’s magnetic separation equipment effectively removes ferrous metal contaminants from your product flow without interrupting your greater process. We offer extensive customization options, allowing us to easily meet your construction standards, facilitate easy installation, and satisfy your exact requirements. Many of the magnetic separation products we have designed for the plastics industry provide targeted solutions for industry-specific problems, such as our High-Temp FF350 Drawer, which tolerates the high temperatures associated with plastics applications such as drying hygroscopic resins.

Metal Detection

Bunting’s range of metal detectors for the plastics industry excel at sensing and removing ferrous, non-ferrous, and stainless steel metals from your process flow. These highly sensitive metal detectors remove all sources of harmful metal contamination from your material while minimizing loss of good product. Some of the specialty metal detectors we offer for the plastics industry include: the quickTRON™ 03R for gravity-free fall applications; the pTRON™ for pneumatic conveying systems; the meTRON™ 07 CI for finished parts inspection; the SL, S,D, and C coils for shredder and grinder protection; and the MMS metal detector for molding machines.

Material Handling Conveyors

For material handling in plastics applications, Bunting offers innovative conveyors that enable you to run your operation more smoothly and safely at every point in the process. For example, our complete line of shredder/grinder feeder conveyors accommodates the many customers who are now regrinding scrap and purging in-house. Many of our conveyors are easily paired with our metal detectors, meaning you can consolidate steps in your manufacturing process while increasing your overall product quality. Bunting offers a complete line of shredder/grinder feeder conveyors with and without metal detectors and magnetic separation to protect your equipment and purify your product along with Eddy Current Separators to further purification of PET and ground plastic.

Magnetic Cylinders

Bunting is also well known for our magnetic printing cylinders. Our range of products includes magnetic die cutting cylinders, two-piece can print cylinders, plastic decorating cylinders, and corrugated carton printing cylinders. Our magnetic cylinders can be used to print on any kind of plastic container with ease. We have invested in state-of-the-art precision machinery to manufacture our magnetic cylinders to exceed OEM specifications.

Many industries fall within the category of plastics, including injection molding, plastics recycling, large-scale manufacturing, and many more. Bunting’s custom design capabilities ensure that no matter what industry you are working in, you will receive a custom designed piece of equipment that meets the exact needs of your specific application. We offer total solutions and have decades of experience in creating the highest quality equipment.

Perfect Plastics Plant Diagram

Now is a GREAT TIME to update your CRITICAL EQUIPMENT and SPARE PARTS. Successful detection and separation of metal will protect your processing equipment from damage, which saves your organization money and downtime.

Click to View a Perfect Plastics Plant diagram.

FF Series Drawer Magnets

FF Series Drawer Magnets are built with strong Rare Earth magnets for strong holding force in gravity flow applications. They are temperature compensated with stainless steel construction and designed for the Plastics Industry.

HF Drawer Magnets

HF Drawer Magnets are for gravity flow applications. They house two or more magnetic cartridges for efficient product separation. For all industries – Food, Grain and Milling, Powder and Bulk, Recycling, and Plastics.

In-Line Magnets

In-Line Magnets are for Gravity or Pneumatic flow applications. Enclosed pipe systems for unobstructed product flow. Rare Earth Magnets are standard. For all industries.

Magnetic Cartridges & Grate Magnets

Grate Magnets and Magnetic Cartridges are engineered to achieve balance between reach-out and holding force. Can be used in all industries.

Plate Magnets

Plate Magnets capture fine metal particles from chutes, suspended in powdery, moist, clumpy, abrasive or bulk materials. Various models available. For all industries including, Food, Powder & Bulk, Grain & Milling, Recycling and Plastics.

Permanent Drum Magnets

Permanent drum magnets are versatile, robust magnetic separators that are well suited to a wide range of applications, including those in the food, plastics, powder and bulk, grain and milling, and metal recycling industries.

Drum Magnet

Drum Magnet Separators come in 3 grades of Rare Earth Magnets and are self-cleaning. They provide continuous removal of ferrous contaminants from product flow.

TurboGrate™ Magnetic Separator

TurboGrate™ Magnetic Separator features a powerful motorized rotating grate magnet to remove ferrous metals from powder and granular materials. For the Food and Powder & Bulk Industries.

High-Intensity Eddy Current Separator

The application of Eddy Current Separators in the recycling sector involves the retrieval or exclusion of non-ferrous metals from materials that lack metallic properties.

Gravity Free-Fall Style Metal Separators – Recycling and Plastics

Automatically detects all ferrous and non-ferrous metals without process interruptions by separating contaminated materials from product flow.

Pneumatic Style Metal Separators

These metal separators detect and reject all metal types in enclosed pipe systems. Easy operation, fast-acting reject flap, and maintenance-free.

Cleaning Systems

Cleaning systems use magnetic and electronic separators to remove both ferrous and nonferrous contaminants efficiently from free-flowing virgin resins, regrind, and recycled plastics.

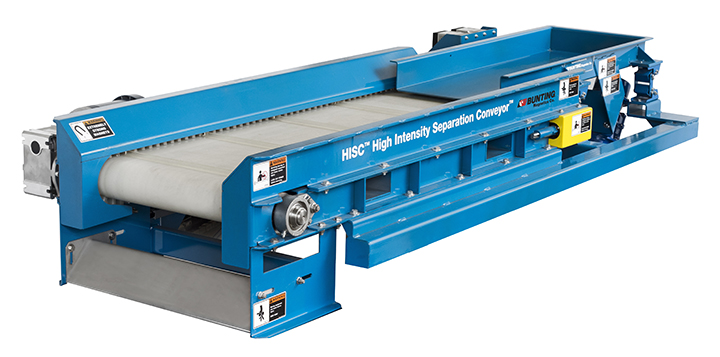

HISC® High Intensity Separation Conveyor®

Designed for extreme high gauss fields of magnetic separation of work hardened stainless steels and removal of lightly magnetic tramp metal fines.

Eddy Current Separator

The Eddy Current Separator core is designed to provide a high level of gauss intensity to enhance separation on a wide range of nonferrous conductive materials and sizes. It is protected with the tough urethane belt and a fiber shell. From aluminum cans to aluminum flakes, our ECS units do an excellent job of throw and separation.

Crossbelt Magnetic Separators for Recycling

Continuous over-conveyor separation for the recycling industry to remove ferrous materials from non-ferrous materials in plastics, wood, tire, metal and municipal scrap recycling.

Shredder Feeder & Discharge Conveyors

Grinder Feeder Conveyors can be used to protect your Shredder from being damaged by separating out the metal contaminant with a magnetic cross-belt or metal detector before the product is transferred to a shredder, and Discharge Conveyors can purify your product on the way out.

DragSlide Conveyors

DragSlide conveyors are totally enclosed and use UHMW drag flights in a chain conveyor design to move and convey film & fiber materials within a sealed conveyor. This makes for a much cleaner facility allowing you to use your employees for production versus clean-up maintenance.

Bale Inspection Conveyors

Bale Inspection Conveyors with metal detectors provide inspection for baled recycled materials. Can be used as either a stand-alone conveyor or as an in-feed conveyor to the shredder line.

Bale Break Conveyors

Bale Break Conveyors break up bales of recycled plastic bottle containers. Heavy-duty construction for rigorous applications. Designed to improve loading and separations efficiency with recycled materials.

Trough-Belted and Transfer Conveyors

Horizontal and inclined regrind or pellet transfer conveyors in any size your application requires. Various belt styles including smooth flat flexed wall, cleated or cleat topped belted conveyors to transfer bulk material to a Granulator or storage facility.

Hump Magnets

Hump Magnets are for high-volume product flow. Offset design breaks up clumps and directs material into magnetic field. Self-cleaning model available. For all industries.

Torpedo Magnets

Torpedo Magnets are used in “Just-in-Time” hopper loaders. They protect plastic molding machines by capturing tramp metal before entering machine. For the Plastics Industry.

Magnetic Pull Test Kits

These test kits has been developed for the purpose of field inspection, measurement and performance analysis of permanent magnetic separation equipment to guard against a lapse in magnetic protection.

Gaylord Cleaning Station

The Gaylord Cleaning Station combines a Bunting drawer magnet with an electronic metal detector to remove ferrous and nonferrous contaminants.

Tunnel Style Metal Detectors with Conveyors

Tunnel style metal detectors can be used to inspect raw foods or for final inspection in a packaging line, to make sure their is no metal in the product before shipping to the customer.

Metal Detectors for Conveyors – Recycling and Plastics

Our metal detection equipment works in conjunction with our conveyors to protect your product and equipment from damage. For under-the-belt and over-the-belt conveying for product inspection.

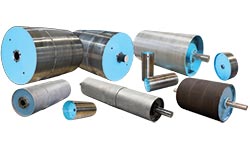

Magnetic Pulleys

Offering superior continuous removal and discharging of ferrous contamination like nails, staples, bolts, and wire from conveyors, all with maintenance free operation.

Wedge Magnets

Wedge Magnets are designed for narrow chutes and protect against tramp metal damage for pellet mills. Shape diverts product flow across collection surfaces. For all industries.

Metal Detector For Film, Web, or Textile Applications

These Flat Coil Detectors prevent costly repairs and production downtime. Units are self-monitoring for added reliability. The ProfiLine features advanced circuitry which reduces false signals and product waste.

Metal Detector Test Standards

They are an easy and economical way to maintain consistent operation and product quality. We offer precision test blocks and ball bearings for metal detector calibration and performance checks.

Move-IT™ Systems

Move-IT™ Conveyors are built to order but priced like stock, available in the most common conveyor sizes and can be custom ordered in a wide range of lengths and widths to fit your application.

Mattop Belted Conveyors

Usually designed for specific applications where the smooth top surface of a mattop belt has advantages over a fabric belted conveyor. Mattop belted conveyors are easier to slide parts across the belt and are better for accumulation applications.