Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

DragSlide Conveyors

Sealed DragSlide Conveyors for Plastic Film, Paper, and Fiber in the Recycling Industry.

Bunting’s sealed DragSlide conveyors are an excellent solution for customers working with plastic film, paper, and fiber in the recycling industry. The DragSlide conveyor was originally designed for the thin mil plastic film industry in order to solve that industry’s problem of static electricity. The DragSlide conveyor also excels at handling other materials that are prone to static charges.

Bunting’s sealed DragSlide conveyors are an excellent solution for customers working with plastic film, paper, and fiber in the recycling industry. The DragSlide conveyor was originally designed for the thin mil plastic film industry in order to solve that industry’s problem of static electricity. The DragSlide conveyor also excels at handling other materials that are prone to static charges.

When plastic films and other fiber materials are shredded, the shredding process generates a very high static charge that causes the material to stick to the steel frames of standard conveyor. Bunting’s DragSlide conveyors are totally enclosed and use UHMW drag flights in a chain conveyor design to efficiently move and convey material within a sealed conveyor, eliminating the daily house cleaning conventional belting conveyors require when handling this material. Running static charged plastic on conventional belted conveyors can result in material being carried around and dropping off on the bottom side, resulting in a heap of material on the floor that demands constant cleaning. Using DragSlide conveyors for handling this type of material results in a much cleaner facility, which allows your employees to focus on production rather than unnecessary cleanup and maintenance.

Bunting’s DragSlide conveyors have extensive customization options and are available in various different styles.

Get a Custom Quote

Dragslide Conveyor – Technical Specifications

• Dragslide conveyors feature a totally enclosed design, using UHMW drag flights to efficiently move and convey material.

• Sealed conveyor eliminates static conveying issues and results in a much cleaner facility.

• Reduces downtime as employees can focus on production instead of time-consuming clean-up and maintenance.

• Available in standard heavy duty units or larger max duty units, with floor supported or mobile bases based on your production needs.

• In-feed hoppers designed to match up to shredder discharge points, allowing for seamless integration with your existing equipment.

• Optional rare earth plate magnets in discharge chute can help eliminate ferrous tramp material in your stream.

• Units equipped with clear sight windows, allowing operator to view material flow within the enclosed system.

Hockey-Stick Style Inclined DragSlide Conveyors

Designed and built to match up to and fit up to shredder discharge openings. After receiving material from a shredder discharge opening, these inclined conveyors can then raise the material to the desired elevation, transfer material to another conveyor, or transfer material directly into an extruder.

Get a Custom Quote

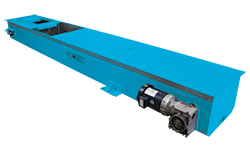

Horizontal DragSlide Conveyors

These conveyors work well for conveying film or fiber materials from one point to another in long horizontal runs. They are great transfer conveyors for a system which is moving free flowing materials and will keep your floor and shop area clean and neat.

• Standard heavy duty units available for clean house conveying.

• Floor supported or mobile bases available based on your facility needs.

• In-feed hoppers designed to match up to shredder discharges or from the preceding conveyor.

• Clear sight windows for viewing material flow.

• Optional high-intensity rare earth plate magnets available.

• UHMW flights allow for extended wear.

Get a Custom Quote