Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

SSSC® Stainless Steel Separation Conveyor™

Patented SSSC® Stainless Steel Separation Conveyor™

Recover Up to 98% of Small and Mid Fraction 300 Series Stainless Steel, and Up to 94% of Large Fraction Stainless Steel from ASR Zurik Lines

PATENTED MAGNETIC CIRCUIT AND OPTIONAL PATENTED AIR KNIFE

With a patent magnetic circuit design of high-intensity neodymium magnets, you can recover up to 98% of small and mid fraction 300 Series Stainless Steel and remove up to 94% of irregular shaped stainless steel from ASR zurik lines – 5” minus in size – from your auto shredding or wire chopping stream. The result is the purest zurik and maximum removal of stainless steel and ferrous dust from wire fraction. Come test your product yourself with our engineers in our Recycling Test Lab to see what the SSSC® Stainless Steel Separation Conveyor™ can do for you and your profitability.

Request a Quote

SSSC® ROI Calculator

LAB PROVEN RESULTS

Bunting Magnetics Lab Tests indicate the SSSC® Stainless Steel Separation Conveyor™ will remove 90-95% of stainless steel from your Zurik medium fraction and 85-94% on Zurik large fraction streams. Our engineers are also seeing that, on Customer Wire Streams before their Wire Choppers, the product is removing approximately 95% of the stainless steel pieces plus a large portion of the foam and fabric that has ferrous dust embedded in it. The total volume of stainless steel and dirt removed from these streams has been running approximately 15% by weight which allows increased production rates, higher purity and considerably less knife damage and down time.

Applications

• ASR Zurik Stainless Steel Recovery & Purification for Domestic Sales

Magnetically pulls out stainless steel from the finder stream or recovery of stainless steel from mid to large fractions to improve purity for domestic sales (estimated purity levels of up to 98% depending on total system layout).

• Appliance Recycling – Stainless Separation Recovery

Magnetically recovering lost stainless steel to improve profitability

• Cleaning ICW Wire before Chopping / Post Chopping Copper Purification

For wire-cleaning applications, it magnetically pulls out stainless steel and ferrous dirt for less knife damage, higher throughput and higher profitability. Tests show total volume of stainless steel and ferrous dirt removed is approximately 15% by weight.

SSSC Stainless Steel Separation Conveyor Features:

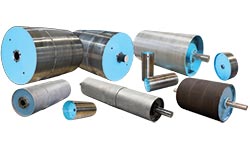

• 8” and 12″ diameter High Intensity Magnetic pulleys to hold 300 Series Stainless Steel of all sizes.

• Packaged put in place system with HD frame – SSSC – Vib Feeder as seen above

• Patented High Intensity Neo Magnetic Circuit Head Pulley

• 2-ply tough urethane belt with 30 mm flexwall and ½” sweeper cleats

• Heavy duty formed 3/16” sideguard with flexwalled belt to seal off and contain flow

• Heavy duty formed 3/16” frame with stainless steel frame at disc and forklift lifting slots for installation

• VFD Controllers to operate between 30 and 120 fpm for effective separation

• General capacities run about 1,000 #/hr/ft width on small fraction, 1,500 #/hr/ft width on mid-fraction, and about 2,000 #/hr/ft width on large fraction.

• Easily adjustable rack and pinion splitter adjustment while in operation.

• Adjustment wheel to easily adjust the bottom splitter forward and back while in operation.

Optional Patented Air Knife and Discharge Hood

• The patented air knife gently blows ferrous foam, dust and cloth from your material to purify the stainless steel stream.

• Discharge hood contains and protects the discharge area.

Optional Vibratory Feeder

• Provides uniform single-layer feeding for maximum separation efficiency

• Customizable width and length to match applications

• Power supply and isolator designed to match flow requirements

• Mild steel or stainless steel fabrication

• Comes complete with controls and can be integrated into existing system

Click here to download our brochure.

Stainless Steel Separation Conveyor – Technical Specifications

YOU MAY ALSO BE INTERESTED IN:

|

|

|

|

|