Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

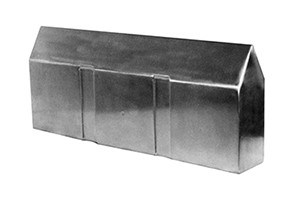

Wedge Magnets

Wedge Magnets Prevent Equipment Damage

Bunting’s Wedge Magnets provide economical protection against the severe damage that tramp metal contamination can cause to equipment in a facility, to product integrity, and to brand reputation. They are ideal for implementation in pellet mills or with other equipment used in processing particulate or semi-solid materials under gravity flow. Wedge magnets are best placed in narrow, vertical, or steeply inclined chutes that are easily accessible and can be opened on a regular basis for equipment inspection and manual cleaning.

The unique shape of Bunting’s wedge magnet resists bridging and diverts the product flow across the front and back collection surfaces of the magnet. Ferrous material is able to be captured and firmly held, preventing it from re-entering the product stream. If ferrous metal contamination is allowed to remain in the product stream, it can cause damage to the other equipment in your facility. Often, metal contamination grates against the metal equipment in your facility, leading to metal-on-metal wear that creates a domino effect of more metal contamination entering your product flow that leads to more equipment degradation down the line. Additionally, if metal contamination is allowed to make its way into your final product, the reputation of your brand may be severely compromised.

Get a Custom Quote

Wedge magnetic separation requires minimal mounting space, meaning they are well suited to being installed in tight, narrow locations. The standard design of a wedge magnet places the magnets within a stainless steel skin to resist wear and corrosion. Wedge magnets can be designed with high-intensity rare earth magnets, which delivers the strongest possible magnetic reach and hold. Wedge magnets are versatile pieces of magnetic separation equipment, and allow for configurations such as installing multiple wedge magnets in a single large chute to enable exceptionally thorough magnetic separation. Bunting’s wedge magnets are a simple, economical magnetic separation solution.

Features Include:

• Design allows for easy installation in difficult areas, such as narrow chutes.

• Require minimal mounting space, allowing for extra ease in installation.

• Stainless steel construction resists wear and corrosion.

• Unique wedge shape helps prevent product build-up and bridging, keeping material moving smoothly through the production line.

• Available in both ceramic and rare earth magnet configurations.

Wedge Magnet – Technical Specifications