Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

MagSlide® Conveyors

The MagSlide Conveyor for Maintenance-Free Operation

Bunting’s MagSlide® magnetic chip conveyors are built to handle your toughest conveying jobs. Designed for the most punishing jobs, the unique magnetic conveying system present in the MagSlide conveyor provides trouble-free, virtually maintenance-free operation. The MagSlide® utilizes powerful magnetic conveying to hold and transport even the dirtiest, most abrasive materials. The rugged construction of the MagSlide conveyor provides dependable performance that is suitable for even the most demanding jobs.

Bunting’s MagSlide® magnetic chip conveyors are built to handle your toughest conveying jobs. Designed for the most punishing jobs, the unique magnetic conveying system present in the MagSlide conveyor provides trouble-free, virtually maintenance-free operation. The MagSlide® utilizes powerful magnetic conveying to hold and transport even the dirtiest, most abrasive materials. The rugged construction of the MagSlide conveyor provides dependable performance that is suitable for even the most demanding jobs.

MagSlide conveyors are engineered to provide you outstanding performance and value. When handling materials such as dirty and oily metal chips, parts, jagged or abrasive scrap, and other punishing materials, conventional belted or steel hinged conveyors risk being damaged. Bunting’s MagSlide conveyors eliminate the problems that conventional conveyors struggle with. The MagSlide® has no external belts, so there’s no risk of belts jamming, tearing, or wearing out over time when conveying sharp, abrasive parts and scrap material. The MagSlide® has no external moving parts, eliminating the risk of such parts failing and compromising productivity and worker safety. Maintenance on the MagSlide® is minimal, and aside from the electric motor, all moving parts are totally enclosed.

Get a Custom Quote

For a Medium Duty MagSlide Conveyor that is Already Built and Ready to Ship SHOP HERE

The MagSlide® is available in several different configurations. Options include horizontal, incline, and angled models with fixed and mobile bases. Additionally, options including hoppers, tanks, and impact plates are also available. We offer three styles of Heavy-Duty MagSlide® Magnetic Chip Conveyors, three styles of Medium-Duty MagSlide® Magnetic Chip Conveyors, and a MagSlide® Low-Profile Conveyor for use in tight spaces. At the bottom of this page, we have included an extensive application guide to assist you in selecting the best MagSlide conveyor for your application.

All of Bunting’s MagSlide® Conveyors feature:

• Rugged construction allows conveyors to handle the toughest jobs with ease.

• No need for labor-intensive supervision, as there are no external moving parts to fail and compromise productivity and worker safety.

• Maintenance is minimal, and except for the electric motor, all moving parts are totally enclosed.

• MagSlide® configurations include horizontal, incline, and angled models with fixed and mobile bases plus hoppers, tanks, impact plates, and other options.

• Continuous chain lubrication with oil-impregnated UHMWPE SlideTrack™

and oil ports to allow extended chain service.

• Oil ports to allow extended chain service

• High-energy Ceramic or Rare Earth Magnets implemented based on your application needs

• Durable stainless steel slider beds with optional manganese add-on.

• Sealed precision drive and take-up bearings.

• Designed with 3-D solid-model technology and precision manufactured on CNC machines.

• Optional submersible housings available.

MagSlide Conveyor – Technical Specifications

Heavy-Duty MagSlide® Magnetic Chip Conveyors

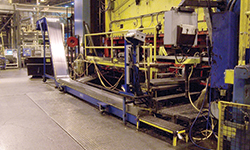

Ideal for use anywhere you need to transfer high volumes of ferrous chips, turnings, and small parts from lathes, mills, or stamping presses or from slitting, forming, and other metalworking operations. Chain-driven, permanently charged high-energy ceramic or rare earth magnets inside the conveyor housing attract and move ferrous material along the conveyor’s stainless steel faceplate with no external moving parts and without the need for an oil filled bath. Optional water-tight housings can be submerged into almost any type of hot or cold liquid. The 8″ thick units come in 12″, 15″, 18″, 24″, 30″, and 36″ widths with optional hoppers and impact plates.

Style A

• Usually straight horizontal feeder conveyors under a large press bringing the scrap out to an inclined conveyor to the dumpster

• Manganese slider-bed option for additional wear resistance

• Up and over stairs and mezzanines available

Get a Custom Quote

Style B

• Horizontal to incline design brings scrap out from under press into a tote.

• Standard fixed supports or optimal mobile bases available.

• Strong ceramic or rare earth magnets on centers from 12″ to 36″ depending on scrap size.

• Manganese slider-bed option for additional wear resistance.

Get a Custom Quote

Style C

• A nose-over unit designed for extending over scrap dumpsters.

• Optional side guards or flared in-feed hoppers available to direct scrap & chips onto the magnetic elements.

• Taller side guards with drain tubers or perforated side guards for coolant.

• Manganese slider-bed option available for additional wear resistance.

Get a Custom Quote

Medium-Duty MagSlide® Conveyors

Horizontal to inclined conveyors are ideal for removing small parts, chips and scrap from machining centers throughout your plant.

Style A

• The 4 ½″ frames come in 10”, 12”, 15” and 18” widths and are well suited for machining, milling, stamping, slitting and forming operations.

• For especially demanding applications, powerful rare earth magnets can be substituted in place of the standard ceramic magnets.

• It is a simple straight horizontal or inclined conveyor to convey parts or scrap from a machine to a dumpster.

Get a Custom Quote

Style B

• It is a straight horizontal to inclined conveyor to convey parts or scrap from a machine to a dumpster.

• These conveyors are also very commonly used in sealed submerged coolant applications or with coolant tanks included for quenching applications.

Get a Custom Quote

Style C

• Well suited for machining, milling, stamping, slitting and forming operations.

• It is a straight horizontal to inclined conveyor with top horizontal extensions to convey parts over a dumpster.

• Optional mobile bases are available.

Get a Custom Quote

Style D

• Captures and moves light ferrous parts and chips in tight spaces.

• Space-saving 3 1/8 ” high frames require less than 4 inches of vertical clearance.

• Designed for use where space is limited and conveyed materials are relatively small, these units fit easily under press dies and at the discharge of many machine tools.

Get a Custom Quote

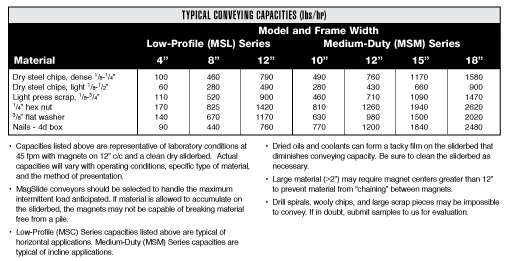

Magslide® Magnetic Chip Conveyors Application Guide

MagSlide® conveyors should be selected to handle the maximum intermittent load anticipated. If material is allowed to accumulate on the sliderbed, the magnets may not be capable of breaking material free from a pile.

Low-Profile (MLS) Series capacities listed above are typical of horizontal applications. Medium-Duty (MSM) Series capacities are typical of incline applications.

Dried oils and coolants can form a tacky film on the sliderbed that diminishes conveying capacity. Be sure to clean the sliderbed as necessary.

Large material (>2”) may require magnet centers greater than 12” to prevent material from “chaining” between magnets.

Drill spirals, wooly chips, and large scrap pieces may be impossible to convey. If in doubt, submit samples to us for evaluation.