Getting Metal Out of Spices – Magnetic Separation and Metal Detection

Any chef can tell you that the first step in cooking a delicious meal is making sure you have a well-stocked spice cabinet. Whether you’re making a casual weeknight dish or a holiday feast, spices are essential to making sure your dinner tastes delicious. No matter what spice you’re using in a dish, it is essential that the spice is free of any harmful metal contamination. That’s where Bunting metal detectors and magnetic separation equipment come in.

Where do Spices Come From?

Spices tend to be cultivated in hot, tropical regions of the world, although some spices thrive in cooler climates. Some of the most popular spices are actually seeds, and these seed spices, such as coriander seed, are grown in Africa, Northern India, and the wheat producing regions of Western New South Wales and South Australia.

The location where a spice is grown, the method spices are harvested, and the way that spices are processed and converted into powders all provide opportunities for metal contamination to enter the product stream. To combat this, magnetic separators and metal detectors detect and remove any harmful contamination that may be lurking within the spices.

Delivery, Grinding, and Screening

During the first stage of processing, the farmed spices are delivered to the processing plant. Then, they will be ground into a powder, and the powder will then be screened to remove any oversized particles.

Delivery

Ideally, any stray pieces of metal contamination will be removed before product enters the processing facility. At this stage, metal contamination is usually larger in size and easier to separate. To enable automated cleaning, shortly after spices are delivered they will be passed over a Drum Magnet. Bunting’s Drum Magnets are available with either high-intensity rare earth magnets or ceramic ferrite magnets. A Drum Magnet is able to automatically separate any magnetically susceptible metal before spices are transported into their initial storage location within the facility.

Prior to Grinding

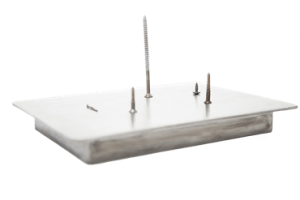

One of the most critical stages in the processing of spices is grinding down the spice seeds into the correct particle size range. During this stage, it is also notable that the grinder is particularly vulnerable to the damages that metal contamination can cause. If the grinder is damaged, there can be a significant cost to the manufacturer in the form of both equipment repairs as well as downtime. Prior to the grinding stage, the Drum magnetic separation used in the previous step will have removed the bulk of ferrous metal contamination. Still, to ensure maximum metal removal, the spice seeds will be fed over the face of a high-intensity rare earth Plate Magnet. By doing this, any remaining ferrous metal contamination will be captured and held by the Plate Magnet, removing it from the product stream and preventing reentry.

Post Grinding and Screening

During the grinding process, any entrapped metal will have been liberated from the spices. The grinding process also sees the grinder and subsequent shifter/screen experiencing general wear and tear. Both liberated metal and tiny metal particles produced by machine wear can serve as new sources of metal contamination within the product that must be removed. To combat this metal, after screened spices exit the sifter, they then pass through either a combination of a Plate Housing Magnet and a quickTRON Metal Detector, or simply the metal detector alone.

Bunting’s Plate Housing Magnet has a wide, open throat that is designed to eliminate any potential flow restriction. Within it are two high-strength facing Plate Magnets. Here, after material falls through the Plate Housing Magnet as a result of gravity, any ferrous metal contained within the product will be attracted to the Plate Magnet’s face, then held against it until the magnet is cleaned manually.

The quickTRON Metal Detector also receives spices via gravity, and goes on to identify and automatically reject all metal contamination—including non-ferrous metals and stainless steel.

Externally Processed Spices

Spice plants are not limited to processing raw seeds into spices. Some plants specialize in preparing mixtures of different spices, such as those used in sauces and taco seasoning packets. Here, the externally-sourced spices need to go through the same rigorous metal removal procedure to make sure no metal contamination is introduced back into the process.

Bag Breaking

When externally prepared spices are delivered to a secondary facility, they typically arrive in bags that must be broken, with the spices then fed into the process. Because this step in the process poses such a high risk for metal contamination, received spices will pass through a Grate Magnet positioned in a hopper as soon as they are emptied out of the bags they arrived in. Bunting’s Grate Magnet features high-intensity rare earth tube magnets that capture and hold both large as well as small, fine magnetically susceptible metals. If the spices being handled are not 100% dry, or if they have a larger particle size range, they may instead pass through a Plate Housing Magnet. The Plate Housing Magnet, with its large, unrestricted throat, excels at the magnetic separation of larger tramp metal.

Pneumatic Feed to Mixer

After spices arrived, they are then pneumatically conveyed to a mixer. Here, a magnetic separator and metal detector, both designed specifically for pneumatic lines, are mounted prior to the mixer. First, Bunting’s Inline Magnet uses a high-strength rare earth magnet to remove tramp ferrous metal contamination. Next, Bunting’s pTRON metal detector will automatically detect and reject both ferrous and non-ferrous metal contamination that may still be present in the spices.

Post Mixing–Prior to Drum Filling for Storage

Whether spices were processed internally or sourced externally, spices will be sorted either individually or blended into a specific mix. If spices are being mixed, such as spices in a taco seasoning blend, they will be processed through a mixer before being packed into drums for storage. The mixer is another point in the process where metal contamination may be introduced into the spices, as the mixer naturally degrades due to wear and tear over time. To combat metal contamination that enters during the mixing step, the combined spice mix is gravity-fed through a Drawer Magnet (with high-strength Neodymium Tube Magnets) and a quickTRON Metal Detector before the spices are fed into storage drums.

Prior to Final Packaging—The Final Check

When the spices are undergoing final packing prior to being sent out as a finished product, the storage drums are emptied into a filling station. This is the final stage before the spices are placed into their finished packaging (which can be a spice jar, a plastic sleeve within a cardboard box, etc.), and this stage should also include a final check for metal contamination.

Here, either a Drawer Magnet or a hopper-mounted Grate Magnet will use high-strength rare earth magnets to remove small, fine ferrous metal contamination. Then, once the majority of the ferrous metal has been removed, a quickTRON Metal Detector will reject any remaining ferrous or non-ferrous metal.

As a final means of quality control, once products have been packaged, they will pass through a conveyor mounted metal detector, such as the meTRON Metal Detector. This detects any metal present in the final packaged product, and protects the consumer from potentially coming into contact with a contaminated jar of spices.

Complete Protection with Magnetic Separation and Metal Detection

It is of utmost importance that spice facilities implement a rigorous metal removal program to ensure the quality of their product and the safety of their customers. Metal contamination can enter the product flow at any stage of the process, but it is especially prone to entering during the grinding and mixing phases. By installing specific designs of magnetic separators and metal detectors at critical locations within the process, the end product will be metal free and the other processing equipment in the facility will be protected from costly damage.