Getting Metal Out of Processed Vegetables and Fruit – Magnetic Separation and Metal Detection

Processed vegetables and fruit are one of the most critical aspects of the food chain. From lettuce and tomatoes at fast food restaurants to peas and carrots in the frozen food section, you can find some form of processed vegetable anywhere you can find food. Often, we don’t even think about the processed vegetables and fruit involved in sauces, juices, canned soup, baby food, and ready-made meals. Because vegetables and fruit are so important to us, both from a health standpoint as well as a flavor standpoint (what would chips be without salsa?!), vegetable processing plants are a vital part of the food manufacturing industry. It’s important to make sure that there is no metal contamination present in vegetables and fruit. But, processing takes an exceptional amount of care and attention since vegetable and fruit products are often delicate and prone to being damaged. Fortunately, Bunting magnetic separation and metal detection can be easily installed into vegetable processing lines and remove metal contamination without damaging valuable produce.

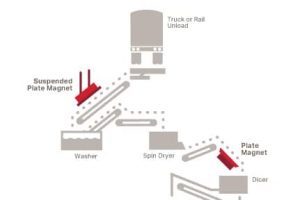

Magnetic Separation and Metal Detection Locations in a Vegetable and Fruit Processing Plant

Stage 1: A Magnetic Separator Handles Untreated Vegetable and Fruit Feedstock

When raw vegetables and fruit are being transported and collected, there is constantly a high risk of metal contamination being picked up. If metal contamination is not promptly removed, that metal contamination will enter the processing plant and go on to cause damage to other processing equipment. To remove this tramp metal, Bunting recommends using a magnetic separator such as a suspended plate magnet or installing a plate magnet within a chute. A suspended plate magnet completely avoids any contact with vegetables and fruit, which reduces the likelihood of damaging them. A suspended plate magnet is positioned above the conveyor that is feeding the washer. Here, metal is attracted to the magnet’s face and held until the magnet is cleaned. Here, the goal is to remove larger tramp metal items such as nails and screws.

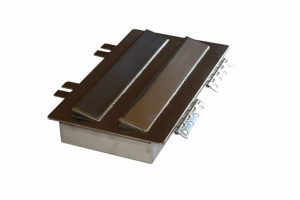

- Technical Information: Suspended Plate Magnet

Stage 2: A Magnetic Separation Prior to Dicing

A dicing machine is highly efficient for cutting vegetables and fruit, and uses many delicate, expensive blades to accomplish this task. If metal contamination comes into contact with these blades, significant damage can occur. This damage is not only expensive, but also can lead to further metal contamination if pieces of the blades break off and enter the product stream. In order to ensure that there is no ferrous metal present, dried vegetables and fruit should be fed over a plate magnet that features one or two tapered steps. This type of installation allows for a higher level of ferrous metal separation compared to installations where a plate magnet is suspended above flowing material. When product flows over the surface of a plate magnet, the vegetables and fruit and metal contamination trapped within them are passing closer to the area of maximum magnetic strength. Additionally, this type of separation scenario sees heavier metal contamination migrate to the bottom of the product flow and onto the face of the plate magnet. The risk for potential damage occurring to the vegetables and fruit as they flow over the plate magnet’s face is limited, as there is no obstruction present. The smooth, tapered steps on the face of the plate magnet allow for easy removal and entrapment of trapped ferrous metal out of the product flow under the lip of a tapered step.

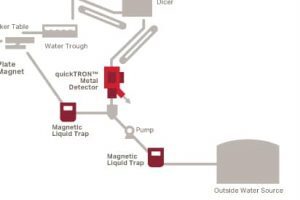

Stage 3: A Metal Detector Handles Undersized Vegetables and Fruit

Smaller, undersized vegetables and fruit, such as those that have been diced, are often treated on a separate process route. Immediately after being diced, these smaller particles are fed through Bunting’s quickTRON metal detector in order to remove any small ferrous and non-ferrous metals. This includes any broken blades from the dicer that may have entered the process. Stainless steel processing equipment is frequently used in vegetable plants, but stainless steel cannot be reliably removed by magnetic separation. For this reason, it is important that product passes through a metal detector in order to ensure all metal contamination is removed.

- Technical information: quickTRON Metal Detector

At this stage in the process, diced vegetables and fruit will be mixed with water from an external source in order to facilitate easier transportation. Before this water enters the process, the water itself will pass through a liquid pipeline magnetic separator or magnetic liquid trap in order to make sure that any rust or other ferrous metal contamination is not introduced into the process. These undersized diced vegetables and fruit are mixed with the water, then reintroduced into the main process.

- Technical information: Liquid Pipeline Magnetic Separator

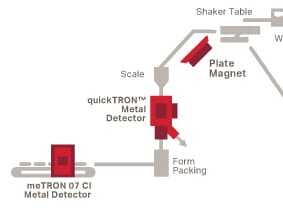

Stage 4: Magnetic Separation and Metal Detection Prior to Packing

For the next step in the process, all vegetables and fruit will be remixed, then fed through a shaker table in order to size them into specific products. Following the shaker tables, these individual sized fractions will pass over a plate magnet with tapered steps, and then go through a final quickTRON metal detector. The plate magnet will be able to capture and hold any remaining ferrous metal contamination, such as fragments of damaged processing equipment originating from broken screens and dicer blades. Then, the metal detector will identify and remove any residual non-ferrous and stainless-steel metal contamination. This equipment combination ensures that all metal will be removed before the final packing stage.

Step 5: A Metal Detector Checks the Final Packed Product

Finally, after vegetables and fruit have been packed, the finished package of processed product will pass through a tunnel-style meTRON™ 07 CI Metal Detector to complete one final check and ensure there is no unexpected metal contamination present in material prior to shipment. Often, this is a required step as part of an internal and external (customer) quality control system.

- Technical information: meTRON™ 07 CI Metal Detector

This is just one example of a vegetable processing plant. Every vegetable processing plant is unique, and presents its own unique layout and processing challenges. Bunting sales representatives are happy to visit your plant and assist you in designing the best metal contamination removal system for your unique plant. For more information about magnetic separation and metal detection for vegetables adnd fruit, Contact us Today.