Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

Auto Shredding

Bunting Equipment for the Auto Shredding Industry

In auto shredding recycling applications, facilities handle massive amounts of recycled material every hour that they are in operation. There is a great deal of valuable material that can be recovered using this recycling method, but there are many unique challenges associated with it as well. Aside from the sheer volume of material handling involved in automobile shredding applications, there are also challenges in recovering the maximum amount of valuable material while separating material that is useless or potentially hazardous. Bunting’s magnetic separation and material handling products assist you in optimizing your car shredding facility.

When you are working with car shredding, or shredding other large metal waste products, it is important to move material quickly and efficiently. To aid in material handling, Bunting offers an extensive range of conveyors, including both magnetic conveyors, non-magnetic conveyors, and various parts and accessories such as conveyor belts. Bunting conveyors are designed with heavy-duty construction that endures the tough environment car shredding facilities present. Magnetic conveyors are an especially good option for automobile shredding applications, as they help maintain a steady pace and uninterrupted flow of material—often performing at significantly higher rates than non-magnetic units. All of Bunting’s conveyors are completely customizable, with options for custom conveyor style, incline angle, vertical height, horizontal extension length, or belt width.

Magnetic Separation and Conveying Equipment to Optimize Your Auto Shredding Business

Bunting’s magnetic separation equipment increases the value of your auto shredding application by separating out metals that are difficult to remove from product streams. This allows for increased metal recovery and significantly higher product purity. Our SSSC® Stainless Steel Separation Conveyor™ and HISC® High Intensity Separation Conveyor® are able to remove paramagnetic work-hardened stainless steel and lightly magnetic tramp metal fines, while the Eddy Current Separator is able to separate a wide range of nonferrous conductive materials. For removing ferrous materials from non-ferrous materials, we offer cross belt magnets to be installed over conveyor belts and deliver outstanding separation without disrupting your operational flow. Bunting equipment optimizes your auto shredding application by improving the flow of your material handling and increasing the purity and value of your recycled product.

Need help finding the right Bunting® Equipment for your Auto Shredding Applications?

Request a Quote for Your Automobile Shredding Facility

Electro Drum Magnets

These heavy-duty magnetic separators are designed to separate and recover large pieces of ferrous tramp metal out of the product stream.

SSSC® Stainless Steel Separation Conveyor™

Separate irregular shaped paramagnetic work-hardened stainless steel – up to 5″ in size – from your recycled materials or in copper wire application.

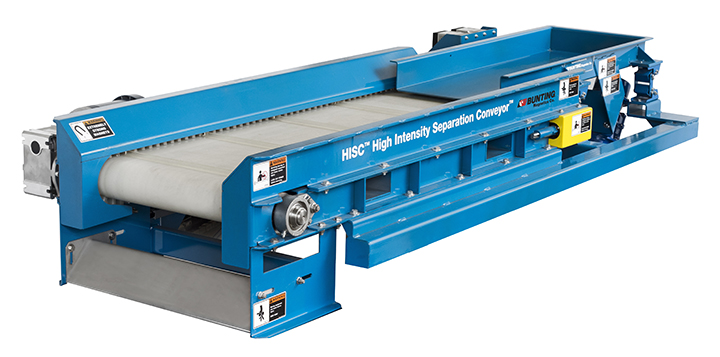

HISC® High Intensity Separation Conveyor®

Designed for extreme high gauss fields of magnetic separation of work hardened stainless steels and removal of lightly magnetic tramp metal fines.

Eddy Current Separator

The Eddy Current Separator core is designed to provide a high level of gauss intensity to enhance separation on a wide range of nonferrous conductive materials and sizes. It is protected with the tough urethane belt and a fiber shell. From aluminum cans to aluminum flakes, our ECS units do an excellent job of throw and separation.

Crossbelt Magnetic Separators for Recycling

Continuous over-conveyor separation for the recycling industry to remove ferrous materials from non-ferrous materials in plastics, wood, tire, metal and municipal scrap recycling.

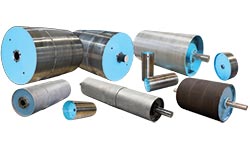

Magnetic Pulleys

Offering superior continuous removal and discharging of ferrous contamination like nails, staples, bolts, and wire from conveyors, all with maintenance free operation.