Get in touch with us at our toll-free number 1-800-835-2526 or request a quote here:

Measuring Magnetic Separator Power

Magnetic separators work by attracting, capturing, and holding particles of ferrous metal to their surface. To successfully separate problematic ferrous metal contamination in any given application, the magnetic separator must meet a certain benchmark of magnetic strength. This strength will typically be stated in the quotation a supplier gives for a magnetic separator, or it will be specified in the tender. Typically, this “magnetic strength” is referred to as “Gauss,” a standard unit of measurement. However, this is a misleading and often meaningless claim, as it is extremely difficult to accurately measure “Gauss” in reality. To provide our customers with a trustworthy and reliable way of physically testing a magnetic separator’s strength, Bunting offers a method known as the “Pull Test.”

Measuring Magnetic Strength

As mentioned before, the magnetic strength of a magnetic separator is frequently referred to in terms of “Gauss,” named after the German scientist Carl Friedrich Gauss. Symbolized by G, Gauss is the centimeter-gram-second (cgs) unit of magnetic flux density. A flux density of 1 G represents one maxwell per centimeter squared (1 MX cm-2).

To measure Gauss, a Gaussmeter is used. However, it must be noted that a Gauss rating on its own provides an incomplete picture of a magnet’s strength. Additionally, gaussmeters can give a range of inaccurate readings dependent on the orientation of the probe and several other variable parameters.

It is common for proposals for products such as tube magnets and plate magnets to include details of length, diameter, and Gauss. However, because a Gauss reading is very difficult to reliably test and prove with any consistency, purchasers and users wind up being unable to verify that the tube magnets they were supplied with actually meet the specification designated in their quote and subsequent order.

Irrespective of Gauss, however, in terms of magnetic separation the user’s objective is simple: the magnetic force must be sufficient enough to enable reliable, consistent attraction and capture of any magnetically susceptible metal. That ability can be measured as a function of the required effort to remove a specific steel item from the magnet’s surface.

The Best Method

In order to measure the force needed to remove a steel item from the surface or face of a magnetic separator, the best method is to use a pull test kit. A pull test kit consists of a magnetic test piece, such as a 6mm ball bearing welding onto a non-magnetic attachment ring, which is then clipped onto the end of a spring balance.

During the test, measurements are taken in the center of the tube magnet or plate magnet as well as on the end poles. These measurements are repeated three times, and the average of the results is recorded as being the necessary force required to remove the magnetic test piece at each point.

The following video explains the Pull Test technique.

This method may not provide any record or indication of the gauss, but it gives a more accurate method of measuring what the magnet is actually being used for—which is to pull out and hang on to ferrous metal. The pull test is also a simple, effective way to gather data that can be used to compare a magnetic separator’s condition over time. This test is repeatable between individuals to generate similar results, whereas gauss testing is often hard to get similar results from different operators. Additionally, a magnetic pull test kit can be used to compare a magnetic separator’s performance with other similar designs of equipment.

Pull Test Kit Experiments

The design of a magnetic separator will considerably vary depending on what application they are intended to be used in. Pull test kits are highly suitable for measuring the magnetic strength of smaller magnetic separators including tube, cartridge, and plate magnets.

Tube or cartridge magnets may be used either alone or as part of a greater magnetic separator configuration, such as in a drawer filter or liquid trap. In a pull test kit, the metal test piece is first attached to the end of the spring balance. Then, it is placed into the magnetic field, where it will be attracted to the magnetic pole.

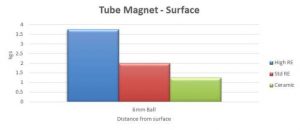

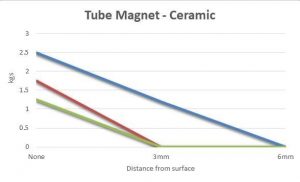

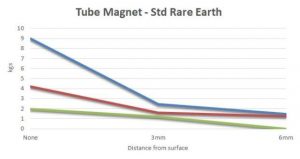

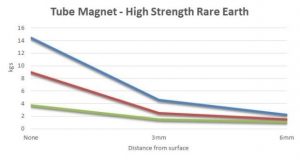

The following tests were taken using three different sizes of steel ball in the magnetic test piece (6mm, 12mm, and 25mm). The tests also introduced a non-magnetic spacer that was used to assess the magnetic strength at specific distances away from the surface (3mm and 6mm). All recorded measurements are in kilograms (kg). The notation “NR” means that no noticeable force was recorded.

Ceramic (Ferrite)

|

Gap

|

6mm Ball

|

12mm Ball

|

25mm Ball

|

|

None

|

1.25

|

1.75

|

2.5

|

|

3mm

|

NR

|

NR

|

1.2

|

|

6mm

|

NR

|

NR

|

NR

|

Standard Neodymium Rare Earth

|

Gap

|

6mm Ball

|

12mm Ball

|

25mm Ball

|

|

None

|

2

|

4.25

|

9

|

|

3mm

|

1.2 |

1.6

|

2.45

|

|

6mm

|

NR

|

1.25

|

1.5

|

High Strength Neodymium Rare Earth

|

Gap

|

6mm Ball

|

12mm Ball

|

25mm Ball

|

|

None

|

3.75

|

9

|

14.5

|

|

3mm

|

1.5 |

2.5

|

4.6

|

|

6mm

|

1.1

|

1.5

|

2.25

|

In every case, there is a significant drop off in magnetic strength when moving farther away from the surface of the tube magnet. This highlights the need for metal contamination to come into contact with the magnet’s surface. Arrangements where tube magnets are configured as a grate (i.e., are lined up and equally space) commonly have a deflector above the gap between the tubes. This deflector directs material in the area of maximum magnetic strength.

These tests highlight the difference in magnetic strength on the surface, with high strength rare earth magnets producing nearly 3 times as much pull compared to ceramic magnets.

Findings during Magnetic Separator Audits

Often, magnetic separator audits will highlight issues that had gone undetected previously. During an audit, the first check focuses on the magnetic separator’s physical integrity, where welds are inspected and wear and damage are assessed. After this, the magnetic separator’s measurements are taken. During magnetic separator audits, the most common findings include:

Weld Failure

Magnetic liquid traps, which are fitted into pipelines, feature tube magnets that are welded into a lid where they then project downwards into product flow. Metal contamination is attracted and captured on the surface of these tube magnets.

In some situations, welds on magnetic liquid traps will fail. This could be due to poor manufacturing techniques, but more commonly it is because the weld has been eaten away by acidic or alkaline liquids and liquid has gone on to seep into the tube and onto the magnets. The magnets then swell and lose magnetic strength before ultimately splitting the outer stainless-steel casing.

Tube Magnet Wear

It is important to check the durability of the wall thickness of a tube magnet, as a tube magnet’s surface can become worn over time as material falls directly onto its surface. Typically, wear occurs on the poles where magnetic particles have been captured. A tube magnet should be replaced once its outer stainless steel casing has been breached.

Weak Tube Magnets

Magnetic separation audits are an opportunity to show the variance in magnetic strength of different tube magnets. It is common to find in facilities that tube magnets have been installed for a long time, and their original specifications have been lost. Once the magnetic strength of these magnets is tested, they are sometimes found to have very poor magnetic strength, meaning they provide little to no protection from metal contaminants. This is of great concern when a tube magnet is installed in a position where it is intended to protect a particular process or piece of equipment in a processing plant where metal contamination damage could result in production downtime and costly repairs.

Conclusion

Performing pull test experiments highlights the importance of physically checking a tube magnet’s real magnetic strength rather than simply relying on a reported “gauss” measurement. A Request for Quote that includes details of the force needed to detach a 6mm steel ball from the surface of a magnetic separator protects the user and ensures that the supplied equipment is exactly as required to do the job it is intended to do.

Using a pull test kit as a standard measurement technique also enables a regular comparative test that can immediately highlight any drop in magnetic strength. This test can be used in annual inspections or audits as part of a quality management system within a facility. When there is a change in pull strength, the cause may be physical (e.g. failed weld, broken magnets from being dropped) or may be due to excessive heat. If a magnetic separator has significantly reduced magnetic force, it may no longer be suitable for use.