Magnetic Separators

Applications: Food, Plastics, Recycling, Mining, Aggregate, Pharmaceuticals, Ceramics, Printing, Textiles, Metalworking

Materials Handled: Dry bulk solids, powders, granules, pellets, liquids, and slurries

Magnetic Separation Products

-

All

-

Food & Pharma

-

Recycling

-

Plastics

-

Powder & Bulk

-

Battery

-

Minerals

-

Aggregate & Mining

-

Ceramics

-

Other

-

Metal Fabrication

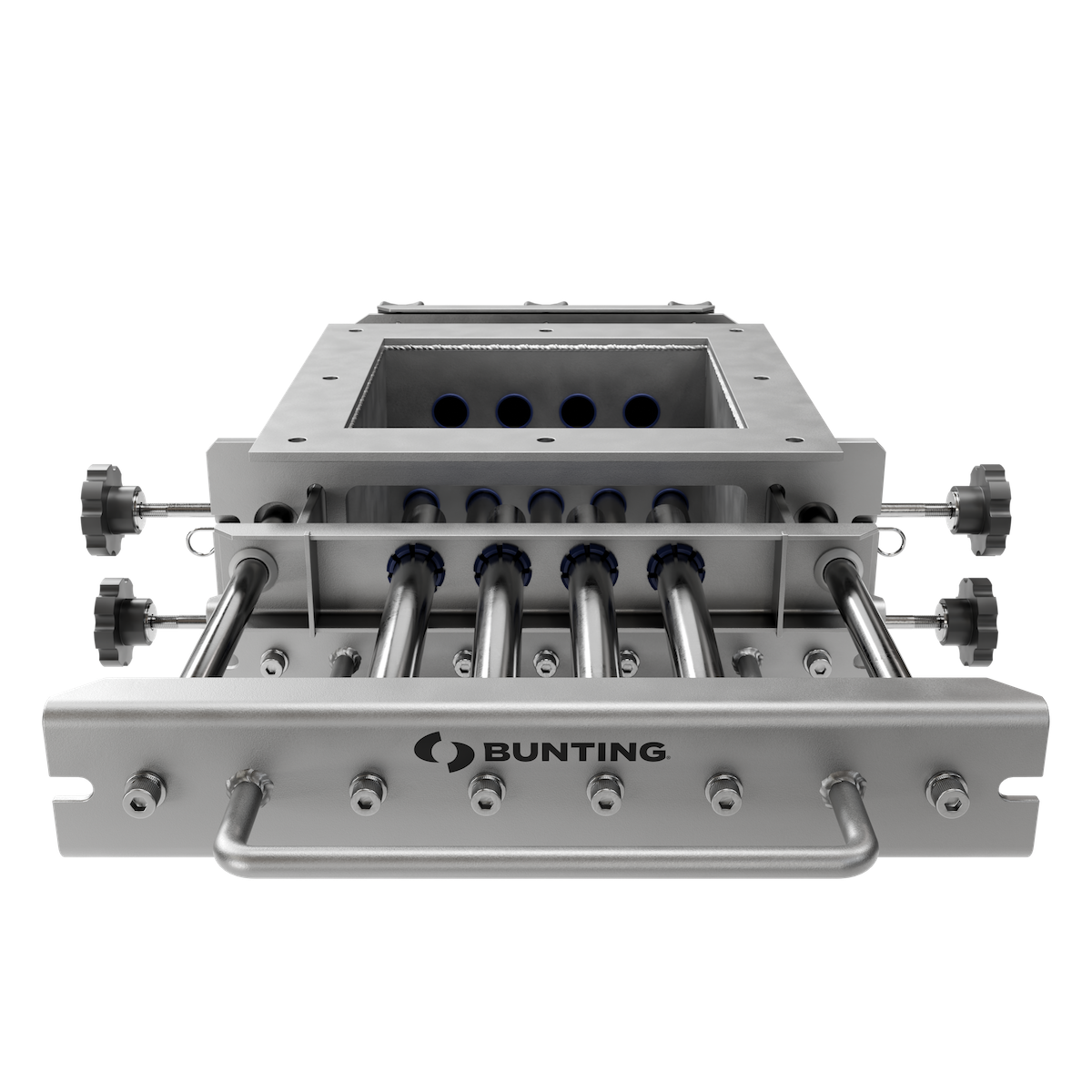

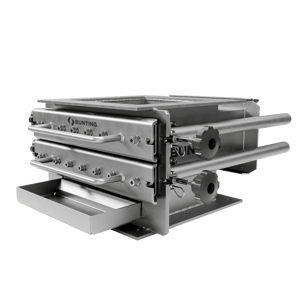

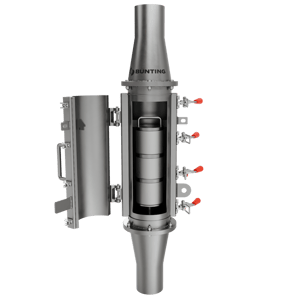

Capture and retain ferrous contaminants from gravity-fed powders and pellets to protect equipment and ensure product purity.

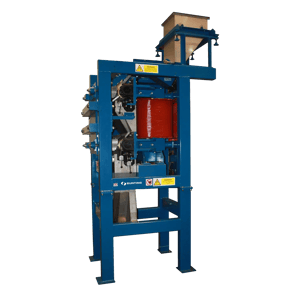

Continuously separates and discharges ferrous metals for automated, high-volume processing.

Captures ferrous contaminants in pneumatic and gravity-fed systems without slowing flow.

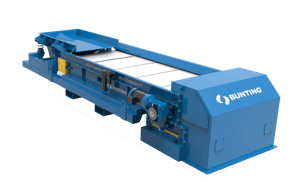

Removes tramp ferrous metals from conveyed bulk materials using overhead magnetic separation.

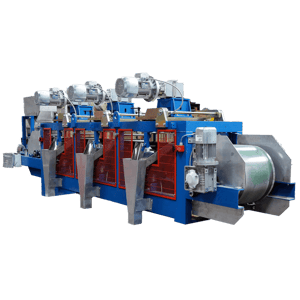

Continuously extracts large tramp iron from conveyor-fed material without halting production.

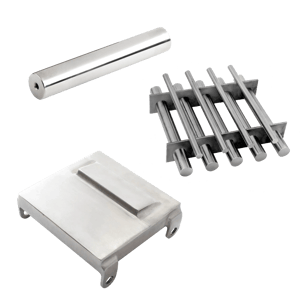

Remove ferrous contaminants from dry, free-flowing materials using stationary magnetic elements that fit easily into chutes, hoppers, and gravity flow systems.

Removes ferrous particles from liquids and slurries, ensuring purity and preventing contamination.

Separates non-ferrous metals like aluminum and copper from material streams.

Extracts stainless steel and weakly magnetic metals to deliver cleaner, higher-purity product output.

Removes fine ferrous contaminants from wet and dry products with high-strength magnetic fields.

Replaces standard head pulleys to continuously remove tramp ferrous metals from conveyors.

Removes tramp ferrous metals from gravity-fed product flow without disrupting throughput.

Mechanical separation method using differences in electrical conductivity to efficiently separate a wide range of materials.

Separates weakly magnetic minerals, like garnet or ilmenite, from non-magnetic materials.

Delivers high-precision separation of weakly magnetic materials using powerful induced magnetic forces.

Separates weakly magnetic minerals from non-magnetic material using high-intensity rotating discs.

The smart solution for fast, powerful cleanup of ferrous metal contamination.

Protect Your Product Quality. Safeguard Your Equipment.

Bunting® magnetic separators are trusted across industries to eliminate metal contamination and protect processing equipment from costly damage. Designed for maximum separation efficiency, our magnetic solutions can be custom-built to suit your material, process, and safety standards—helping you achieve cleaner end products, less downtime, and peace of mind.

We support industries including: food processing, dairy, grain and milling, plastics, chemicals, oil, recycling, textiles, and more. Whether you're removing tramp metal from powders, pellets, granules, liquids, or slurries, Bunting has the solution. To further enhance product safety, Bunting offers metal-detectable gaskets and grommets—standard in many of our food-grade systems. If a gasket chips or breaks, the fragment is immediately captured by the magnetic element or flagged by downstream metal detection or x-ray inspection.

Engineered to Your Standards

Every Bunting separator can be built to your specifications—whether you need food-grade, sanitary-grade, USDA-approved, or custom construction. Our engineers will help you select the right configuration, magnetic strength, and cleaning method (manual or self-cleaning) for your application.

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.