Aggregates, Mining & Biomass

Magnetic Separation and Metal Detection

for Aggregate, Mining & Biomass

Protect Your Equipment. Ensure Product Purity. Minimize Downtime.

Bunting delivers engineered metal separation and detection solutions purpose-built for the demanding environments of aggregate, mining, and biomass operations. Our rugged systems remove ferrous and non-ferrous contaminants from bulk materials—safeguarding critical equipment, preserving product quality, and improving your bottom line.

Why Metal Contamination Is a Serious Risk

Prevent Crusher Damage from Tramp Metal

Tramp metal causes serious damage to jaw crushers, impactors, screens, and conveyor belts. Even small fragments can crack liners, jam screens, or rip belting—resulting in costly repairs and lost production.

Ensure Product Quality and Regulatory Compliance

In biomass processing, metal contamination can introduce secondary pollution during combustion or pelletizing. Aggregate and mining operations must meet strict specifications to deliver clean, contaminant-free material.

Our systems intercept these risks before they reach your critical processing equipment.

Magnetic Separation and Metal Detection Solutions

Bunting delivers a full line of equipment engineered to withstand harsh, high-volume industrial operations:

Self-cleaning systems for continuous tramp metal removal—available in permanent, air-cooled, and oil-cooled electromagnetic models.

Suspended Magnets

Ideal for removing ferrous contaminants from conveyors handling crushed rock, coal, sand, or biomass.

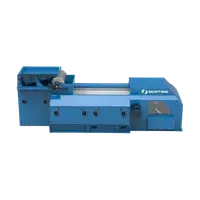

Drum Magnets and Magnetic Pulleys

Extract metal from high-flow materials in quarry, mining, or wood processing applications.

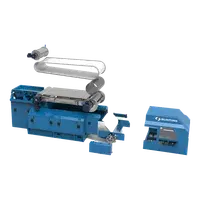

Eddy Current Separators

Designed to separate non-ferrous metals like aluminum and copper from biomass, ash, and mineral streams.

Tunnel and Conveyor Metal Detectors

Detect ferrous and non-ferrous metals in bulk materials—protecting screens, crushers, and other downstream systems.

Every plant is different. That’s why Bunting equipment is built to integrate seamlessly with your production flow, physical layout, and contamination profile.

-

Built to match your belt width, suspension height, and burden depth

-

Available in standard and deep-reach configurations

-

Multiple mounting and drive options for permanent or electromagnet setups

-

Designed for low maintenance, easy cleaning, and long-term durability

Our magnetic separation and metal detection equipment is used in:

-

Quarrying and aggregate plants (stone, gravel, sand)

-

Hard rock and coal mining operations

-

Biomass fuel and wood pellet production

-

Cement, fly ash, and mineral processing plants

-

Recycling and concrete batch plants

Aggregates, Mining & Biomass

-

All

-

Magnetic Separation

-

Metal Detection

-

Electromagnetic Filters

Continuously extracts large tramp iron from conveyor-fed material without halting production.

Removes tramp ferrous metals from conveyed bulk materials using overhead magnetic separation.

Continuously separates and discharges ferrous metals for automated, high-volume processing.

Detects tramp metal—especially manganese steel—in harsh environments. Prevents damage, reduces downtime, and improves operating efficiency.

Replaces standard head pulleys to continuously remove tramp ferrous metals from conveyors.

Removes fine ferrous contaminants from wet and dry products with high-strength magnetic fields.

Separates non-ferrous metals like aluminum and copper from material streams.

Animation

Talk to an Application Engineer

Need to remove metal from crushed stone, mineral feed, or biomass fuel? Our experts will help you specify the right magnetic separator or metal detector to protect your line.