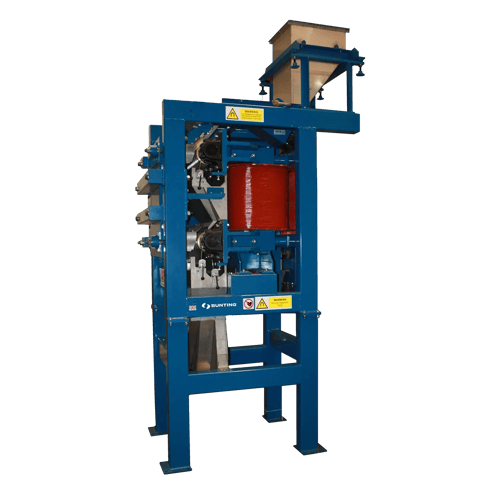

Induced Roll

| Magnet | Electromagnet |

| Strength | 22,000 Gauss |

| Material | Dry |

| Separates | Paramagnetic minerals |

Features

Variable magnetic field strength for separation optimization.

Processes particle sizes from 45 microns to 2mm across various industries, including ceramics and recycling.

Can handle mineral feeds up to 80°C, suitable for demanding industrial environments.

Animation

- About

- Benefits

- Operation

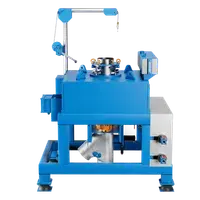

The Induced Roll Magnetic Separator (IRS) is a high-intensity dry magnetic separator designed to remove weakly and moderately magnetic materials from non-metallic minerals. By generating an electromagnetic field of up to 2.2 Tesla (22,000 Gauss), the IRS effectively separates materials such as mica, iron-coated silica, and other paramagnetic minerals from non-magnetic materials like feldspar, silica sand, and zircon.

This technology is widely used in the ceramics and glass industries to purify raw materials and is gaining traction in recycling applications where fine, weakly magnetic particles must be recovered. The IRS is built around a steel roll, which is magnetized by an electromagnet positioned between a bridge bar and a pole piece. It handles feed materials with particle sizes ranging from 2mm down to 45 microns and delivers consistent performance in continuous processing environments.

With decades of proven use, the IRS is recognized as one of the most robust and versatile dry magnetic separators available.

Adjustable Magnetic Field: Power to the electromagnetic coils can be varied to match material characteristics.

Variable Roll Speed: Allows fine-tuning of retention time for improved separation accuracy.

Customizable Roll-to-Pole Gap: Accommodates different feed size ranges for optimal processing.

Handles Heated Material: Capable of processing materials at elevated temperatures up to 80°C.

Minimized Static Charge: Generates limited static buildup, reducing impact on separation performance.

Durable Construction: Engineered for minimal maintenance and low spare parts requirements.

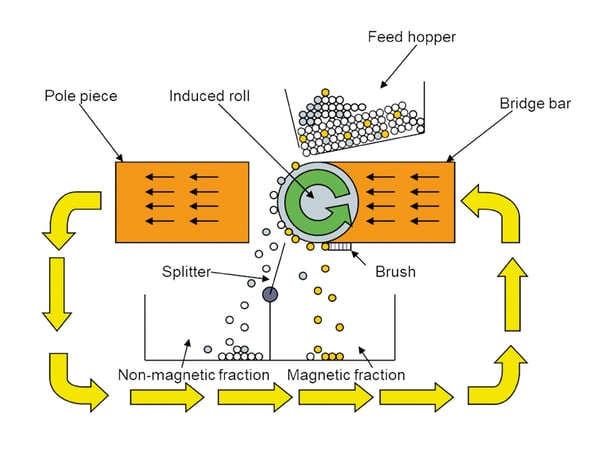

Material Feeding:

- A controlled amount of material is fed onto the rotating magnetically induced roll.

- The material feeds from a hopper or vibratory feeder.

- The roll typically rotates at speeds between 80 to 120 RPM.

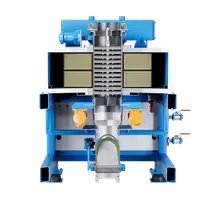

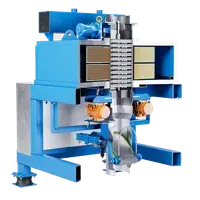

Separation Process:

- Paramagnetic materials are held to the roll surface.

- Non-magnetic materials fall freely, unaffected by the magnetic field.

Material Collection:

- Non-magnetic materials discharge away from the roll.

- Magnetic materials are deflected by the roll.

- A brush often helps remove the magnetic materials from the roll.

Separation Control:

- A splitter plate is placed between the two product streams for clean separation.

- A second splitter can be added to create a 'middlings' stream (very weak magnetic materials mixed with non-magnetics).

Enhanced Efficiency:

- Many units have two induced rolls in series.

- This allows for a double pass, improving separation efficiency and overall performance.

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.