Inline Magnets

| Magnet | Ferrite, Neodymium |

| Material | Dry powders, granular materials |

| Separates | Ferrous and weakly magnetic particles |

| Conveying | Gravity-fed and pneumatic pipelines |

Options

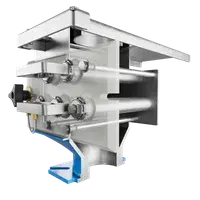

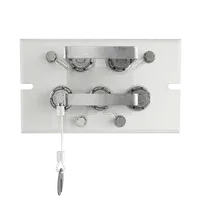

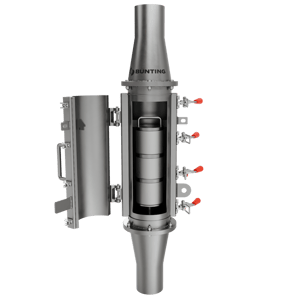

Captures ferrous contaminants from pneumatic conveying systems without interrupting product flow. Its powerful rare earth magnetic circuit and streamlined housing maintain line pressure while protecting downstream equipment.

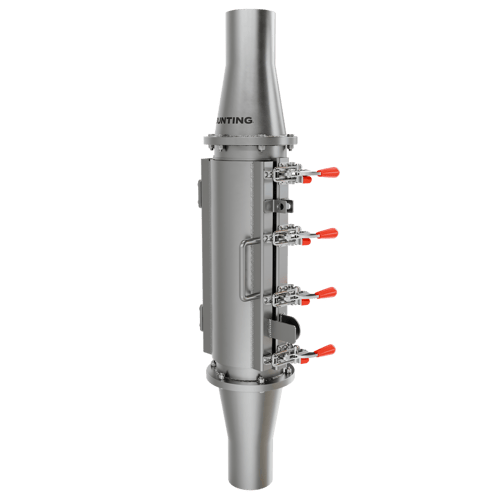

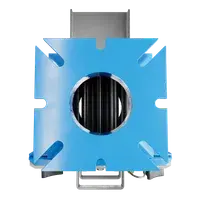

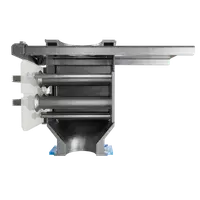

Removes fine ferrous particles from pneumatically conveyed granular or pelletized materials. Its tapered, aerodynamic design maintains flow velocity while maximizing contact with a high-strength magnetic cartridge.

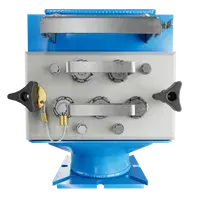

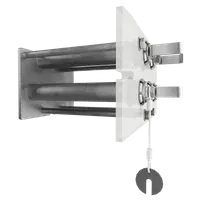

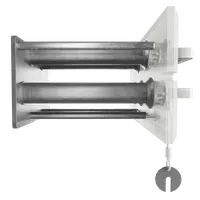

Efficiently captures ferrous contaminants from gravity-fed product streams. Its tapered step magnet design ensures maximum tramp metal removal even in tight spaces, maintaining smooth product flow and protecting downstream equipment.

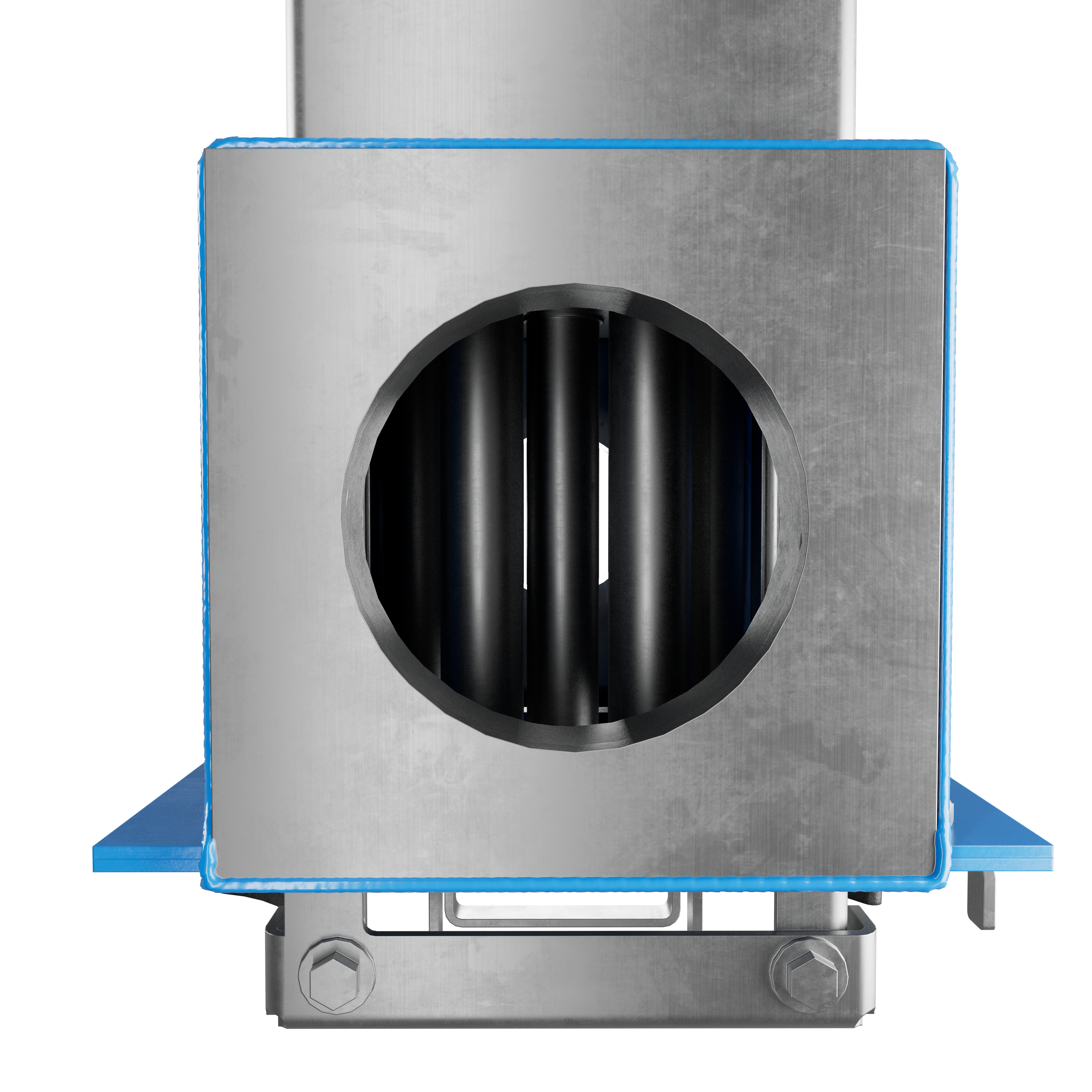

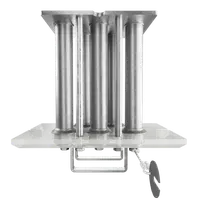

Heavy-duty cylindrical magnet housed in stainless steel. Ideal for removing large tramp metal from high-volume gravity flow applications.

Animation

- About

- Benefits

- Tech Specs

- Drawings

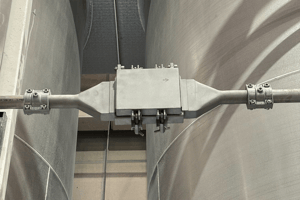

Inline Magnets are magnetic separators used to remove ferrous contaminants from materials conveyed through pipelines. Designed for both gravity-fed and pneumatic systems, they support a wide range of industrial applications, including food processing, plastics, ceramics, and bulk material handling.

Constructed from durable stainless steel, Inline Magnets are available in standard, food-grade, and sanitary models to meet USDA and FDA requirements. Depending on the model, they feature either side-mounted plate magnets (as in Gravity and Pneumatic Inline Magnets) or centrally located cartridge or cone-style magnets (as in center-flow) to ensure efficient metal capture.

Available with either Ceramic or Neodymium Rare Earth magnets, these systems can be tailored to specific application needs. Ceramic magnets offer a wider but weaker field suitable for capturing larger metal pieces, while Neodymium magnets provide a stronger, more focused field ideal for fine metal particles.

Inline magnets are typically used in pipelines ranging from 50mm (2") to 250mm (10") in diameter, with custom sizes available. Many models feature easy-access doors or hinged housings for quick cleaning, minimizing downtime during maintenance.

Whether your goal is product purity, regulatory compliance, or equipment protection, Inline Magnets provide powerful, reliable magnetic separation that keeps your process running smoothly.

Minimal Product Flow Restriction

Inline magnets are engineered to maintain smooth product flow, reducing the risk of blockages or material build-up during operation.

Targeted Magnetic Strength

Equipped with Ceramic Ferrite or Neodymium Rare Earth magnets, inline magnets offer customizable magnetic fields.

Reliable Ferrous Metal Capture

Strong magnetic fields ensure that captured metal remains firmly attached to the magnetic surface, even under high-flow conditions.

Quick & Easy Cleaning

Most models feature hinged plates or removable cartridges, allowing for fast, tool-free cleaning during maintenance cycles.

Flexible Sizing & Installation

Available for pipeline diameters from 50mm (2") to 250mm (10"), inline magnets integrate easily into both new builds and retrofits.

Cross-Industry Versatility

Ideal for food, plastics, ceramics, recycling, and bulk solids processing—inline magnets meet a wide range of contamination control needs.

Improved Product Safety

By removing tramp metal, inline magnets help ensure product purity and compliance with industry safety standards like HACCP and FDA guidelines.

Reduced Maintenance & Downtime

Durable, low-maintenance designs extend equipment life and minimize unscheduled production interruptions.

Magnet Type

- Ceramic Ferrite

- Neodymium Rare Earth

Magnetic Strength

- Varies by model and magnet type

- Neodymium offers higher gauss for fine contaminants

- Ceramic provides broader reach for larger tramp metal

Pipeline Diameter

- Standard sizes: 50mm to 250mm (2" to 10")

- Custom options available upon request

Body Material

- 304 or 316 stainless steel

- Food-grade and sanitary construction available (USDA/FDA compliant)

Flange Options

- Standard sizes: 50mm to 250mm (2" to 10") used with compression clamp

- Custom round, rectangular, or sanitary flange adapters available

Maximum Pressure (Pneumatic Models)

- Rated for dilute-phase pneumatic systems up to 15 psi

Models

- Gravity Inline Magnets (GIM) – For sloped gravity-fed systems

- Center Flow Magnets (CFM) – For dry powders with high exposure

- Pneumatic Inline Magnets (PIM) – For pneumatic conveying lines

- HD Center Flow Magnet -For high-volume gravity flow applications.

Optional Features

- Tapered magnetic face or step face for improved ferrous capture

- Pipe adapters and transitions for easy installation

- Sanitary seals and FDA-approved gaskets

Complete the form below and the drawings will be emailed to your inbox.

Application Photos

-0476-200h.png?width=300&name=Bunting_Pneumatic_In_Line_Magnets(HR)-0476-200h.png)

-0506.png?width=300&name=Bunting_Pneumatic_In_Line_Magnets(HR)-0506.png)

-0471.png?width=300&name=Bunting_Pneumatic_In_Line_Magnets(HR)-0471.png)

-0470.png?width=300&name=Bunting_Pneumatic_In_Line_Magnet(HR1)-0470.png)

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.