Overband Magnets

Remove Tramp Iron. Protect Equipment. Maintain Throughput.

Bunting® Overband Magnets, also known as Crossbelt Magnets, are powerful, self-cleaning magnetic separators built to remove tramp ferrous metal from conveyed material. Installed inline or across the belt, they protect crushers, shredders, and other downstream equipment from costly metal damage and keep operations running without unplanned stops. Offered in permanent or electromagnetic models, Bunting Overband Magnets are widely used in mining, aggregates, recycling, and other heavy industrial applications around the world.

Overband Magnet Models

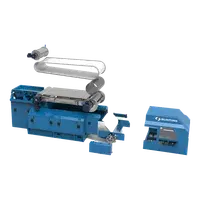

Permanent Overband Magnet (PCB)

The most economical and low-maintenance option for continuous tramp metal separation. These self-cleaning magnets use high-strength permanent magnet blocks to extract ferrous metal from conveyed materials.

Ideal for:

- Mobile crushers and screeners

- Lightweight ferrous recovery

- Construction and demolition recycling

Key Features:

- No power required for magnetic field

- Cleated self-cleaning belt system

- Available in to suit working gaps up to 400mm (16")

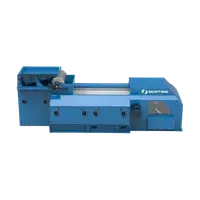

ElectroMax Air-Cooled Overband Magnet (EMAX)

This high-intensity electromagnetic separator is 185% stronger and 25% lighter than conventional permanent overband (crossbelt) magnets. Ideal where weight, space, and enhanced metal separation are critical.

Ideal for:

- Mobile recycling and crusher systems

- Mining, quarrying and bulk aggregate systems

- Removal of challenging ferrous metal such as digger teeth

Key Features:

- Powerful electromagnetic coil

- Air-cooled design, no oil present

- Highest magnetic power to weight ratio of any overband magnet

- Optional armored belt

- Supplied with air or oil cooled transformer rectifiers

Oil-Cooled Electromagnetic Overband Magnet (OCW)

Engineered for heavy-duty applications where maximum separation strength is essential. Oil-cooled electromagnets achieve deep field penetration for removal of large tramp metal pieces from deep burden depths.

Ideal for:

- Mining, quarrying, and bulk aggregate

- Bulk handling terminals and waste to energy plants

- Deep burden depths and high-speed belts

Key Features:

- Rugged construction with armored belt options

- Works at increased suspension heights up to 800mm (32")

- Suitable for belt widths up to 2400mm (96")

- ATEX rated models available

Air-Cooled Electromagnetic Overband Magnet (ACW)

Engineered for demanding environments where reliability and low maintenance are critical. The heavy-duty air-cooled electromagnetic overband range is available in over 300 sizes, providing powerful tramp metal separation without the need for oil circulation systems.

Ideal for:

- Mining, quarrying, and bulk aggregate

- Recycling and waste management facilities

- Bulk handling terminals and waste to energy plants

Key Features:

- Air-cooled design – no oil present, reducing maintenance

- For conveyors from 500mm (20") up to 3000mm (118") wide

- Effective suspension heights up to 1000mm (40")

- Permanent extension magnets can be attached to extend the discharge zone away

- ATEX rated models available

Model Comparison Chart

| Features | Permanent (PCB) | ElectroMax (EMAX) | Oil-Cooled (OCW) | Air-Cooled (ACW) |

| Magnet System Power Source | None | Electromagnetic (Air Cooled) | Electromagnetic (Oil Cooled) | Electromagnetic (Air Cooled) |

| Cooling Method | N/A | Air | Oil | Air |

| Typical Belt Widths | 450mm (18") to 1800mm (72") | 1000mm (40") - 1800mm (72") | 500mm (24") to 2400mm (96") | 500mm (24") to 3000mm (118") |

| Max Suspension Height | Up to 400mm (16") | Up to 500mm (20") | Up to 800mm (32") | Up to 800mm (32") |

| Optional ATEX rating | Yes | No | Yes | Yes |

| Optional Armored Belt | Yes | Yes | Yes | Yes |

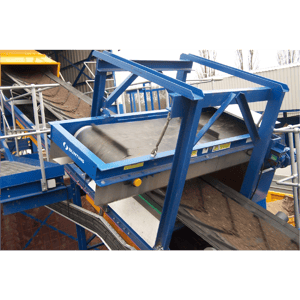

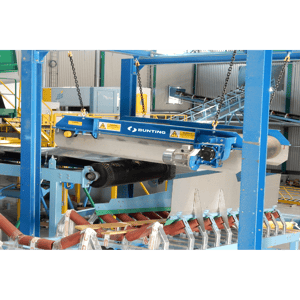

Application Photos

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.