Energy Storage and Battery

Magnetic Separation Metal Detection & Conveyors for Battery Storage & Recycling

Recover Materials. Protect Equipment. Keep Operations Safe and Efficient.

Whether you're recycling lithium-ion cells, sorting manufacturing scrap, or managing critical raw materials, our solutions help you reclaim value, reduce risk, and ensure regulatory compliance.

Our systems are used in battery recycling and storage operations to:

- Remove ferrous and non-ferrous metal contamination from shredded battery material

- Protect critical equipment like shredders, granulators, separators, and processing lines

- Improve purity of battery grade lithium carbonates and graphite

- Streamline safe, automated material flow through every stage of the recycling process

Safeguarding Equipment and Maximizing Material Recovery

Metal contamination in battery recycling can compromise recovery rates, damage processing equipment, and create serious safety risks. Bunting’s magnetic separators and metal detectors are engineered to extract ferrous, non-ferrous, and weakly magnetic metals; protecting your operation while improving material purity and compliance.

Separation and Handling Solutions

We deliver systems for efficient processing of battery materials, from shredded EV cells to manufacturing scrap. Our magnetic separation and material sorting solutions are engineered to handle mixed feedstocks. Whether recovering valuable cathode and anode materials or separation for downstream processing, our technology is built to meet the challenges of modern battery recycling and manufacturing.

Solutions

Our range of separation equipment removes ferrous, non-ferrous, and weakly magnetic metals such as steel casings, battery tabs, and shredded components from mixed battery feedstock. These systems are integrated at critical points like conveyor transitions, material infeed, or downstream of shredders to protect equipment, improve purity, and maximize recovery rates of valuable battery metals.

To identify ferrous tramp contamination, such as battery terminal posts. Designed for rugged recycling environments, these detectors ensure maximum safety and purity; whether mounted inline with conveyors, or integrated into automated sorting lines.

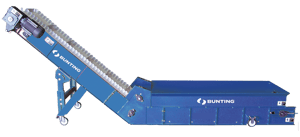

Bunting conveyors handle active materials, mixed scrap, and deconstructed battery cells with precision and control. Our corrosion-resistant, sealed, and liquid-tight designs prevent electrolyte leaks, reduce manual handling, and seamlessly integrate with metal detection systems—ensuring safe, efficient throughput from intake to final sorting.

Industries Served

Magnetic separators and metal detectors are essential in battery recycling facilities to recover valuable metals and remove contaminants from shredded EV batteries, consumer electronics, and manufacturing scrap. These systems improve recovery rates and reduce equipment failure.

Battery packs from electric and hybrid vehicles are processed using integrated conveying, separation, and detection systems. These technologies safeguard equipment from ferrous and non-ferrous debris while helping reclaim critical materials like lithium, nickel, and cobalt for reuse in new battery manufacturing.

Our separators ensure battery-grade material quality in lithium-ion, EV, and automotive battery manufacturing, while reducing waste in the production process.

Consumer electronics and small-format batteries are processed using magnetic separation systems that recover aluminum, copper, cobalt, nickel, gold and other valuable materials. Our solutions lead to improved purity standards for more efficient downstream chemical processing.

Energy Storage and Battery Manufacturing Equipment

-

All

-

Magnetic Separation

-

Electromagnetic Filters

-

Material Handling

Continuously separates and discharges ferrous metals for automated, high-volume processing.

Removes fine ferrous contaminants from wet and dry products with high-strength magnetic fields.

Separates weakly magnetic minerals, like garnet or ilmenite, from non-magnetic materials.

View

Ensure reliable movement of ferrous and non-ferrous materials.

FAQ's

A: Returned products and e-waste shipments often contain undeclared or damaged lithium-ion batteries. When these items pass through shredders, crushers, or compactors, thermal runaway can occur—resulting in intense fires, explosions, or toxic gas release.

Bunting helps mitigate this risk in multiple ways:

- Upstream Detection: Our high-sensitivity metal detectors scan incoming material streams to identify lithium-containing items before they reach crushing or shredding stages. Real-time rejection prevents battery fragments from triggering combustion under pressure.

- Magnetic Separation: While lithium itself is non-magnetic, battery housings and tabs often contain steel or other ferrous materials. Our magnetic separators remove these markers—acting as an early warning signal and reducing the likelihood of intact batteries making it downstream.

- Automated Conveying Isolation: Our conveyor systems can be designed with divert gates, fire-rated enclosures, and zoned material control—minimizing the spread of hazardous material and allowing for safe isolation of suspect loads.

- Workflow Integration: By placing metal detectors before high-pressure mechanical processing points, you create an intelligent screening layer that flags potential threats and stops fires before they start—preserving your facility, reducing liability, and maintaining compliance with fire codes and insurance requirements.

In short, Bunting systems act as your facility’s first line of defense—detecting, separating, and isolating battery threats before they become warehouse emergencies.

A: Magnetic separation is highly effective for removing ferrous and weakly magnetic metals from shredded lithium-ion, EV, and automotive battery feedstocks. When combined with other separation technologies such as eddy current, rare earth roll, and electrostatic separation, it helps achieve high-purity recovered streams, improving downstream recovery efficiency and ensuring battery-grade material quality.

A: Absolutely. Liquid-tight and touchless conveyors protect against leaks and preserve battery integrity. Roller and screw systems maintain throughput and orientation for automated sorting.

A: We supply separation equipment to process all major chemistries, Li-ion (EV, electronics), LiFePO₄, NiMH, lead-acid; and recover cobalt, nickel, copper, aluminum, graphite, black mass and more.

A: Highly customizable: modules can be retrofitted or scaled, from pilot lines to full industrial systems, with full remote monitoring, automation, and regulatory compliance support.

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.