Powder and Bulk

Magnetic Separation & Metal Detection for Powder & Bulk Solids

Eliminate Contamination. Protect Equipment. Safeguard Product Quality.

From fine powders to coarse aggregates, manufacturers and processors across industries depend on clean, contamination-free materials. Bunting delivers integrated magnetic separation, metal detection, and conveying solutions engineered specifically for the handling of powders and bulk solids.

Why Metal Contamination Matters

In bulk material handling, even a small piece of metal can cause significant damage. Metal contamination—whether from processing equipment wear, raw material impurities, or accidental introduction—can:

- Damage downstream equipment like mills, mixers, extruders, and baggers

- Compromise product purity and lead to recalls or regulatory violations

- Cause line shutdowns, costly downtime, and lost revenue

- Tarnish your brand reputation with customers and auditors

Whether you're moving material by gravity, pneumatic, or mechanical means, protecting your product and equipment from tramp metal is critical to safe, efficient operations.

Solutions

Bunting magnetic separators remove ferrous metal contamination from powders, granules, flakes, pellets, and abrasive solids. Common system locations include:

- Gravity chutes and hoppers

- Pneumatic transfer lines

- Belt conveyors and discharge points

- Feeders and pack-out stations

We offer high-strength magnets in multiple configurations to match your application—ensuring maximum separation efficiency without restricting flow.

Our all-metal detectors identify and reject ferrous, non-ferrous, and stainless steel contaminants—whether free-flowing, embedded, or coated. Designed for:

- Pneumatic conveying systems

- Free-fall material flows

- Conveyor belts and packaging lines

Advanced digital signal processing, auto-calibration, and product effect compensation ensure high sensitivity with low false alarms—even in difficult conditions like powdered sugar, cocoa, or fine chemical blends.

Bunting conveyors are engineered to transport bulk solids efficiently while incorporating inline detection and separation. Systems can be customized for:

- Vertical or horizontal orientation

- Sanitary or heavy-duty construction

- Integrated reject mechanisms

- Powder containment and dust control

Materials Handled and Industries

We design solutions for materials of varying particle sizes, densities, and flow characteristics, including:

- Fine powders (e.g., flour, starch, talc, carbon black)

- Granular solids (e.g., sugar, fertilizer, salt, coffee, grains)

- Fibrous materials (e.g., hemp, wood shavings, paper pulp)

- Abrasive or dense solids (e.g., cement, minerals, foundry sand)

The powder & bulk solids label spans a wide range of sectors. Bunting protects processing lines in:

- Food & Beverage – Ingredients, grains, sugar, spices, chocolate, dairy powders

- Pharmaceuticals – Active ingredients, excipients, nutritional powders

- Plastics & Rubber – Resin pellets, regrind, colorant powders

- Mining & Minerals – Cement, silica, kaolin, ores, sand

- Chemicals – Detergents, fertilizers, pigments, industrial powders

- Pulp & Paper – Cellulose, fillers, recycled paper fibers

- Pet Food & Animal Feed – Meals, grains, supplements

- Cosmetics – Talc, powders, mica-based ingredients

- Hemp & Agriculture – Biomass, pre-extraction feedstocks

No matter the industry, Bunting designs systems to meet safety, regulatory, and quality standards.

Powder and Bulk Processing Equipment

-

All

-

Magnetic Separation

-

Material Handling

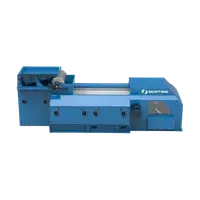

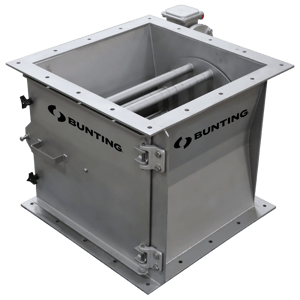

Capture and retain ferrous contaminants from gravity-fed powders and pellets to protect equipment and ensure product purity.

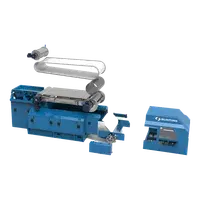

Continuously separates and discharges ferrous metals for automated, high-volume processing.

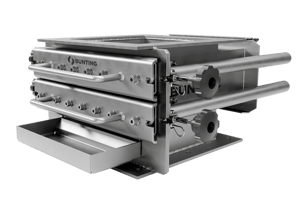

Captures ferrous contaminants in pneumatic and gravity-fed systems without slowing flow.

Removes fine ferrous contaminants from wet and dry products with high-strength magnetic fields.

Removes tramp ferrous metals from gravity-fed product flow without disrupting throughput.

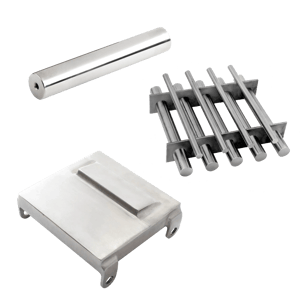

Remove ferrous contaminants from dry, free-flowing materials using stationary magnetic elements that fit easily into chutes, hoppers, and gravity flow systems.

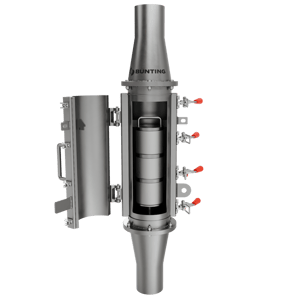

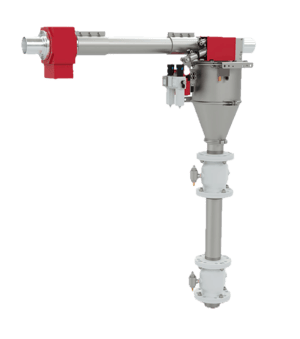

Remove metal contaminants from powders, granules, and pellets in vacuum or pressure pneumatic lines. Ideal for plastics, chemical, and food processing.

Detects and removes metal contaminants from liquid, slurries, pastes and meat in pumped product streams. Custom-designed to fit any pipeline application.

Engineered for difficult-to-flow powders, TurboGrate’s rotating magnetic action breaks up clumps and ensures thorough removal of metal contaminants.

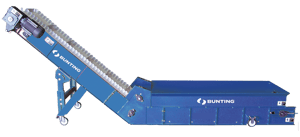

Efficiently move powders and bulk solids with conveyors that include magnetic separators and metal detectors for contaminant removal.

FAQ's

A: Our solutions capture and reject ferrous, non-ferrous, and stainless steel contamination—including fines, wires, and embedded particles.

A: No. Our detectors compensate for product effect and are optimized for powders, granules, and dusty materials.

A: Bunting designs each system to match your material’s flow characteristics. For challenging powders, we offer staggered magnetic arrays, smooth housing finishes, and low-profile configurations.

A: Ideal locations include material intake points, pre-processing stages (mixing, blending), and final pack-out. Our team can audit your line and recommend optimal installation points.

A: Yes. We offer systems engineered for dense-phase, dilute-phase, or gravity-fed transfers—complete with dust-tight and sanitary options.

A: Most customers achieve ROI after preventing just one equipment failure or batch contamination. Additional savings come from reduced downtime, fewer recalls, and better process efficiency.

Talk to an Application Engineer

Handling abrasive powders, dense minerals, or fibrous biomass? Our experts will help you select the right magnetic separator or metal detector to protect your equipment and keep your material flow clean.