Ceramic Purification

Ensuring Quality and Performance in Ceramic Production

Bunting provides advanced magnetic separation solutions tailored to the ceramic industry. Our equipment is designed to efficiently remove ferrous and paramagnetic minerals, ensuring cleaner ceramic materials, reducing production waste, and enhancing profitability across various wet and dry applications.

Achieving High Purity in Ceramics

Bunting's advanced magnetic separators remove ferrous and para-magnetic particles from ceramic powders, slips, and glazes. Our equipment ensures high-purity output, minimizing defects and maximizing the quality of finished ceramic products.

Reduce Quality Control Rejects

Bunting's range of magnetic separation equipment reduces quality control losses and improves sustainability in the energy intensive ceramic production process.

Ceramic Processing Applications

Bunting supports various sectors with tailored solutions:

Remove ferrous metal contaminants from clay, silica, and other raw materials to improve ceramic product quality.

Remove ferrous metal contamination to reduce firing losses.

Remove ferrous metal contaminants to improve whiteness in sinks, toilets, and other sanitary products.

Enhance cosmetic appearance of premium tableware products.

Ensure the purity of advanced ceramic materials used in electronics, fibreoptic grade silica, aerospace, and other high-tech applications.

Ceramics

-

All

-

Magnetic Separation

-

Electromagnetic Filters

-

Material Handling

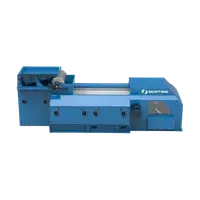

Removes fine ferrous contaminants from wet and dry products with high-strength magnetic fields.

Removes ferrous particles from liquids and slurries, ensuring purity and preventing contamination.

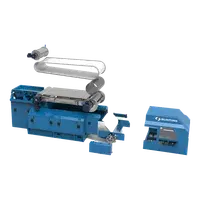

Continuously separates and discharges ferrous metals for automated, high-volume processing.

Separates weakly magnetic minerals, like garnet or ilmenite, from non-magnetic materials.

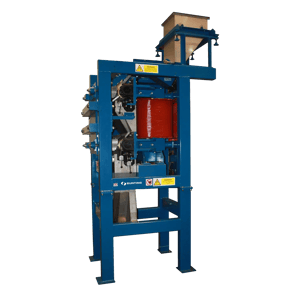

Delivers high-precision separation of weakly magnetic materials using powerful induced magnetic forces.

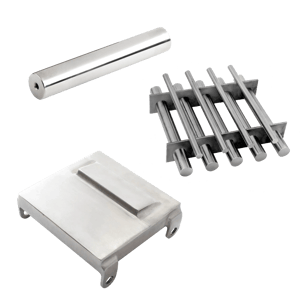

Remove ferrous contaminants from dry, free-flowing materials using stationary magnetic elements that fit easily into chutes, hoppers, and gravity flow systems.

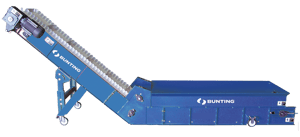

Bunting offers a range of conveyors that streamline workflows while integrating seamlessly with our separation technologies.

Talk to an Application Engineer

Need to remove ferrous metal from clay, feldspar, quartz, or ceramic material? Our experts will help you specify the right magnetic separator to remove contamination, and ensure product purity.