Rare Earth Roll

| Magnet | Neodymium |

| Material | Dry |

| Separates | Weakly magnetic materials |

| Particle Size | 75 microns to 15mm |

Features

Utilizes powerful neodymium magnets to effectively separate weakly magnetic materials.

Processes particle sizes from 75 microns to 15mm, suitable for various applications.

Offers adjustable roll speed, splitter position, and feed rates for optimum separation efficiency.

Animation

- About

- Benefits

- Operation

The Rare Earth Roll Magnetic Separator (RE Roll) stands at the forefront of high-intensity magnetic separation technology, offering unparalleled performance in purifying dry minerals and waste materials. This separator utilizes powerful Neodymium Iron Boron (NdFeB) magnets to generate an ultra-strong magnetic field, capable of removing weakly magnetic materials from non-magnetic materials.

Originally developed for the ceramics and glass industries, the RE Roll has expanded its applications to include stainless steel and brass separation from e-waste recycling processes. It can also be used to separate anode from cathode material in electric vehicle batteries.

The RE Roll's specialized head pulley ensures maximum separation efficiency. This advanced technology allows for the extraction of even the most weakly magnetic minerals, such as muscovite mica, and iron stained quartz.

Applications of the Rare Earth Roll span across multiple industries:

- Mineral Processing: Feldspar, silica sand, and high-purity quartz purification

- Ceramics: Removal of fine iron from spray-dried ceramics

- Recycling: Processing of cullet, granulated steel slag, and plastic waste

- Urban Mining: Recovering precious metals from e-waste

High-Intensity Separation: The Rare Earth Roll effectively separates weakly magnetic materials from non-magnetic ones, enhancing product purity and value.

Adjustable Parameters: Variable roll speed, feed rate and adjustable splitter plate allow for fine-tuning of separation efficiency to suit different material characteristics.

Versatile Application: Capable of processing particles from 75 microns to 15mm, making it suitable for a wide range of industries and materials.

Efficient Design: The unique roll configuration maximizes magnetic field strength while ensuring smooth material flow and high throughput.

Customizable Options: Available in various sizes and configurations to meet specific application needs and processing capacities.

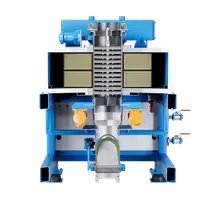

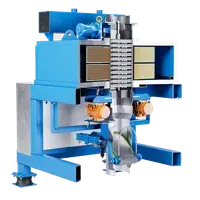

- In operation, a dry material mix, with particle sizes ranging from 75 microns to 15mm, is fed as an even monolayer onto a short-centred thin conveyor belt.

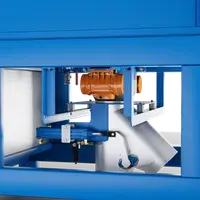

- As the material moves into the separation zone of the magnetic head pulley, magnetically susceptible materials are held to the roll, while non-magnetic materials continue on their normal trajectory.

- A carefully positioned splitter then separates the two fractions: magnetically susceptible minerals and non-magnetic materials. In certain applications, it is also possible to create a third 'middlings' fraction that consists of weakly magnetic materials.

- The trajectories of all fractions can be controlled and adjusted by changing the speed of the conveyor belt, which is managed through an inverter located in the main control panel.

Application Photos

Want To Know More?

Contact one of our sales representatives to discuss your specific needs and interests.