Eddy Current Separators

Advanced Non-Ferrous Metal Separation Technology

For more than 30 years Bunting® has engineered high‑performance Eddy Current Separators (ECS) that repel non‑ferrous metals — such as aluminum, copper and zinc — from non‑conductive material streams. The result: higher product purity, higher metal yield and lower operating costs.

Applications: Plastic Recycling, Auto Shredder Residue (ASR), Electron Waste (E-Waste Recycling, Municipal Solid Waste (MSW) & Aluminum Can Recovery, Glass Recycling, Wood and Biomass Recycling

How Eddy Current Separation Works

-

Short centered conveyor presents material to a high‑speed magnetic rotor housed inside a non‑metallic shell.

-

Rapid polarity reversal induces eddy currents in conductive particles (Fleming’s left‑hand rule).

-

Magnetic repulsion throws non‑ferrous metals, while inert material falls naturally.

-

Adjustable splitter isolates the two fractions for clean recovery.

Eddy Current Separator Models

| Model | Magnet Rotor Ø | Poles | Belt Widths | Best For |

|

High‑Intensity Eccentric (HIE) |

190mm (7.5") |

24 |

300-1250mm (12"-50") |

Fines ≥ 3 mm (e‑scrap, granulated plastic) |

|

High‑Intensity Concentric (HIC) |

300mm (8") |

24 |

300-2000mm (12"-80") |

Mixed recyclables ≥ 10 mm |

|

R‑Type |

190mm (5") |

12 |

750-1250mm (30"-50") |

Household & C&I waste ≥ 20 mm |

|

Can Sorter (CS) |

120mm (4.5") |

6 |

500 or 600mm |

Aluminum beverage cans |

Quick‑Change Belt

The HIE, HIC and R-Type models feature an under‑frame cantilever jacking system. One technician can swap the conveyor belt without removing the rotor, minimizing downtime and safeguarding rotor alignment.

Why Choose Bunting's Eddy Current Separators?

- Designs

- Throughput

- Options

Eccentric vs. Concentric Eddy Current Separators: What’s the Difference?

Bunting manufactures both eccentric and concentric rotor eddy current separators, each designed for specific material characteristics and recovery goals. The key distinction lies in the position of the magnetic rotor within the head pulley and how the magnetic field interacts with the conveyed material.

-

In concentric designs, the rotor sits centrally inside the pulley, delivering a symmetrical magnetic field. This setup offers balanced repulsion and is ideal for coarser non-ferrous metals in steady feed conditions.

-

In eccentric designs, the rotor is offset within the pulley shell, focusing the magnetic field at a single discharge point. This improves the separation of small, lightweight, or low-conductivity particles, especially when targeting fines under 10 mm.

Choosing between the two depends on your material’s particle size, conductivity, throughput, and purity requirements.

Comparison Table: Eccentric vs. Concentric Eddy Current Separators

| Feature | Eccentric Rotor ECS | Concentric Rotor ECS |

|---|---|---|

| Rotor Position | Offset from center | Centered in pulley |

| Magnetic Field | Focused | Symmetrical around shaft |

| Best For | Fines < 10 mm | Bulkier metals > 10 mm |

| Throw Efficiency | Intensified localized repulsion | Strong, even throw |

| Precision Sorting | Excellent | Good |

| Common Models | HIE (High-Intensity Eccentric) | HIC (High-Intensity Concentric) |

Typical Applications & Throughput

(Metric range followed by rounded imperial range)

| Application | Particle Size | Recommended ECS | Max Capacity (t / h / m) |

|---|---|---|---|

|

Aluminum Dross (Oversize) |

20 - 200 |

HIC |

20 |

|

Aluminium Dross (Screened) |

0 - 20 |

HIE |

5 |

|

Household Refuse (unsorted) |

0 - 300 |

R Type |

20 |

|

Household Refuse (pre-sorted) |

50 - 200 |

R Type or CS |

10 |

|

Glass - Cullet (Bottles Crushed) |

0 - 50 |

HIC |

20 |

|

Glass - Light Bulbs (Crushed) |

0 - 30 |

HIE |

7 |

|

Incineration Ash |

0 - 40 |

HIC |

20 |

|

Plastic Waste (Granulated) |

3 - 10 |

HIE |

2 |

|

Scrap (Oversized Frag) |

0 – 150 |

HIC |

20 |

|

Scrap (Screened Frag) |

10 - 40 |

HIE |

15 |

|

UPVC Window Frames (Screened) |

10 - 40 |

HIE |

20 |

|

WEEE (Electronic Scrap) |

0 - 30 |

HIE |

20 |

|

White Goods |

40 - 150 |

HIC |

20 |

|

Woodchip |

0 - 60 |

HIC |

13 |

Optional Extras & Integration

-

Sequenced PLC control cabinet

-

Ceramic coating on carbon‑fibre rotor shell

-

Custom chassis with primary ferrous separation (drum, pulley or overband magnet)

-

Rotary or static belt brushes for sticky/wet feed

-

Laboratory‑scale units available for trials in Bunting’s UK Recycling Test Facility

FAQ's

The Eddy Current Separator (ECS) uses a high‑speed magnetic rotor to generate repulsive magnetic forces that separate non‑ferrous metals (like aluminium, copper, zinc) from non‑conductive materials in recycling streams. It’s commonly integrated with a drum magnet that first removes ferrous metals.

Bunting offers four ECS models tailored for different particle sizes and applications:

-

High‑Intensity Eccentric (HIE) — for small non‑ferrous metals down to 3 mm

-

High‑Intensity Concentric (HIC) — for general use, non‑ferrous metals above 10 mm (16/64")

-

R‑Type ECS — for general household recycling, non‑ferrous metals above 25 mm (1")

-

Can Sorter (CS) ECS — cost‑efficient option designed for recovering aluminium cans

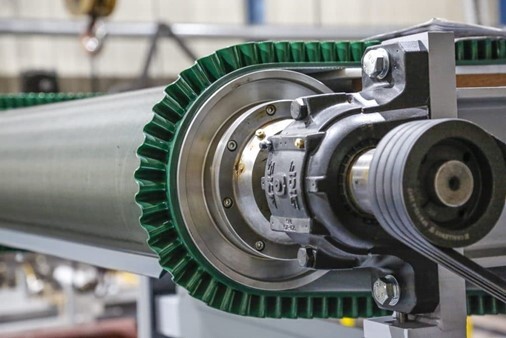

An Eddy Current Separator consists of a short belt conveyor with its drive located at the return end, and a high-speed magnetic rotor system installed at the discharge end. The magnetic rotor, housed within a separately rotating non-metallic drum, operates at speeds of up to 3,000 revolutions per minute, while the outer drum cover rotates at the same speed as the Eddy Current Separator’s belt conveyor.

As the rotor spins at these high speeds, it produces a changing magnetic field. The strength of this field depends on the rotor's speed and the number of magnetic poles.

When a conductive metal piece passes over the rotor and through this changing magnetic field, an eddy current is induced within it. These eddy currents, in turn, create their own magnetic fields that oppose the original magnetic field (Lenz’s Law). This interaction generates a repulsive force that pushes the object away from the magnetic field (Fleming’s Left-Hand Rule).

Inert, non-conductive materials (such as glass, plastic, etc.) simply fall off the rotor due to gravity—their distance thrown is determined solely by the belt speed. In contrast, conductive metal pieces are repelled and thrown farther from the rotor.

A splitter plate is positioned between these two material streams to enable separation. By adjusting the belt speed, rotor speed, and splitter plate position, the Eddy Current Separator can be configured to suit the specific characteristics of the customer’s material.

The HIE, HIC. and R-Type model feature a cantilever jacking system beneath the hinge frame, allowing one person to lift and hold the conveyor from one side. After drive belt removal, the main belt can be easily and quickly replaced without removing the rotor—minimizing downtime and simplifying maintenance.

-

Recover non‑ferrous metals from shredded cars, aluminium cans, WEEE, etc.

-

Remove non‑ferrous contaminants from cullet, plastics, woodchip and other waste materials

Applications span metal recycling, glass re‑melting, plastics reuse, wood processing, and waste-to-energy operations.

Application Photos

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.