Recycling

Increase Recovery Across Every Recycling Stream

Recycling operations handle more than just metals and plastics. From wood waste and glass to construction debris, e-scrap, and mixed municipal material, profit depends on how efficiently you recover value while protecting critical equipment.

Bunting designs magnetic separation, metal detection, and conveying systems to help recyclers remove damaging metal contamination, improve material quality, and keep lines running at high throughput. Every system is engineered to fit your process, your layout, and your material mix so you can recover more value without slowing production.

How Bunting Systems Improve Recycling Operations

- Remove damaging ferrous and non-ferrous metal from mixed material streams

- Protect grinders, shredders, screens, and optical sorters from costly downtime

- Improve product purity for resale or downstream processing

- Maintain consistent performance in high-volume recycling environments

- Integrate seamlessly into existing recycling lines

- Support a wide range of materials beyond metal and plastics

Recycling Applications

Bunting magnetic separators, eddy current separators, and conveying systems are fundamental to metal recycling operations where recovery rates drive profitability. These systems recover ferrous, non-ferrous, and stainless steel from scrap and residue streams, helping recyclers increase metal yield, improve product quality, and maximise value at high throughput.

Plastics recycling operations depend on clean, consistent material streams to produce high-quality regrind and pellet. Bunting magnetic separation and metal detection systems remove ferrous and non-ferrous metal contamination from plastic material, protecting extruders and granulators while improving product quality and line reliability.

Bunting magnetic separators and eddy current separators play a critical role in MRFs where material purity and uptime drive profitability. These systems remove ferrous and non-ferrous metals from mixed recyclables, improving downstream sorting efficiency, protecting optical sorters and screens, and increasing the value of recovered paper, plastic, and aluminum streams.

In wood recycling and biomass operations, tramp metal poses a serious risk to grinders, chippers, and hammermills. Bunting magnets and metal detectors capture nails, screws, and other metal contamination from inbound wood waste, reducing equipment damage, minimizing downtime, and improving the quality and consistency of processed wood products.

Glass recycling operations rely on clean material streams to maximize cullet quality and reduce wear on processing equipment. Bunting magnetic separation systems remove ferrous and non-ferrous metal contamination ahead of crushers and screens, helping recyclers improve product quality, reduce maintenance costs, and maintain consistent throughput.

Construction and demolition recycling involves highly variable material streams where effective metal removal is essential. Bunting systems recover ferrous and non-ferrous metals from concrete, brick, wood, and mixed debris, allowing recyclers to generate additional revenue from recovered metals while protecting processing equipment and improving overall line efficiency.

E-scrap and specialty recycling operations depend on precise separation to recover value from complex material streams. Bunting magnetic and eddy current systems separate ferrous and non-ferrous metals from shredded electronics and specialty materials, increasing recovery rates while protecting sensitive downstream equipment.

MRFs handle mixed streams where metal recovery directly impacts profitability. Bunting magnetic and eddy current systems recover ferrous and non-ferrous metals from high-volume material flows, creating cleaner product streams and adding metal revenue without slowing throughput.

Solutions

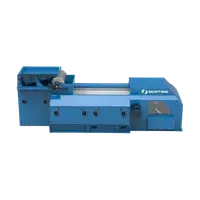

Magnetic separation is critical to both protecting equipment and increasing recovery across recycling operations.

Bunting magnetic separators remove ferrous metal from material streams before it can damage shredders, grinders, crushers, and screens. Capturing ferrous metal early prevents costly downtime while turning tramp metal into a recoverable product stream. Cleaner material improves downstream processing, supports higher recovery rates, and helps recyclers increase revenue without slowing throughput.

Higher recovery rates. Protected equipment. More value per ton.

Metal that goes undetected creates risk and lost value.

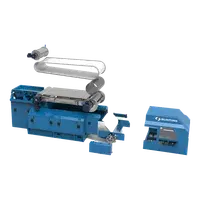

Bunting metal detection systems are designed to identify ferrous and non-ferrous metal that escapes upstream separation. By locating contamination before it reaches critical equipment, these systems help prevent costly damage while capturing additional recoverable metal. The result is improved line reliability, cleaner material streams, and more value recovered from every ton processed.

Material that doesn’t move efficiently costs money.

Bunting conveyors are built to keep recycled material moving at the pace your operation demands. Designed for abrasive, high-volume recycling environments, our custom conveyor systems support steady throughput and consistent separation across mixed material streams. By matching conveyor design to your layout, tonnage, and material type, you reduce bottlenecks, limit rehandling, and keep revenue moving from intake to final product.

Talk to an Application Engineer

Every recycling operation is different. Talk to Bunting about your material stream, throughput, and recovery goals, and we will help you identify the right combination of magnetic separation, metal detection, and conveying to increase recovery and protect your equipment.

FAQ's

Recycling operations face different challenges depending on material type, throughput, and process layout. The questions below address common considerations around metal recovery, equipment protection, and system performance across a various recycling applications.Bunting systems are designed to handle a wide range of materials including wood waste, glass, mixed municipal recyclables, construction debris, plastics, e-scrap, and metal-bearing residue streams. Systems are built to perform in abrasive, high-tonnage recycling environments.