Manufacturing & Capabilities

Advanced Manufacturing Capabilities at Bunting Magnetics

At Bunting Magnetics, manufacturing isn’t just what we do—it’s the foundation of everything we deliver. Across our globally integrated facilities in Newton (KS), DuBois (PA), Berkhamsted and Redditch (UK), we combine the power of precision machinery, skilled craftsmanship, and advanced automation to produce reliable, high-performance magnetic assemblies and components for industries worldwide.

Full-Spectrum Manufacturing, In-House

Our vertically integrated operations allow us to control every stage of production, from raw materials to final quality assurance. This ensures faster turnaround times, consistent quality, and total flexibility for custom solutions.

Core Capabilities Include:

- CNC Machining & Milling: Precision milling, turning, and routing deliver exact tolerances for metal and plastic components across a range of volumes.

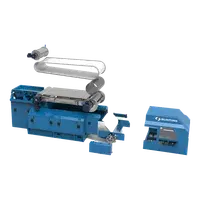

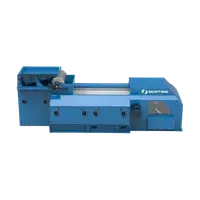

- Stamping & Press Work: High-speed and high-tonnage presses create repeatable components critical for magnetic assemblies and sub-systems.

- Fabrication & Welding: Our fabrication teams build durable, application-specific housings and frameworks with expert welding and finishing.

- Paint & Powder Coating Booths: In-house paint and finishing systems allow us to meet appearance, durability, and industry-specific coating standards.

- Water Jet Cutting: Enables intricate, high-pressure cutting across a range of materials without thermal stress or distortion.

- Automated Robotic Assembly: Robotics ensure repeatable, high-throughput production lines with consistent precision.

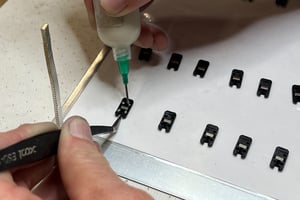

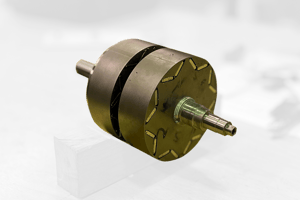

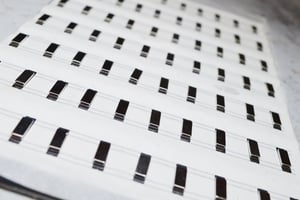

- Magnet Production & Magnetizing Equipment: We don’t just source magnets—we build them. Our custom machinery manufactures compression bonded magnets in-house, giving us full control over magnetic properties, shapes, and materials. With on-site magnetization, we customize field strength and polarity for each application.

Engineering-Driven Manufacturing

Each product we manufacture is backed by our engineering team’s close collaboration with production. From prototyping and tooling design to process optimization and final testing, we combine creativity with control to meet exacting specifications. Our engineers and machinists are not siloed—they’re synchronized. This alignment ensures seamless transitions from CAD model to finished part.

Quality Without Borders

Whether you're working with our team in the US or the UK, you'll experience:

- ISO-certified quality systems

- Common design and production protocols

- Centralized documentation and traceability

- Localized support with global resources

- From high-volume OEM runs to complex custom builds, we manufacture with a mindset of reliability, repeatability, and responsiveness.

What We Do

-7387.jpg?width=300&name=Hitachi_High-Tech_XRF_Analyser(HR)-7387.jpg)

.jpg?width=300&name=Adcutech%20Job%20-%20Talk%20to%20Dave%20Richards%20(1).jpg)