Mineral Processing

Magnetic and Electrical Solutions for Mineral Processing

Efficient, high-purity mineral processing is essential for maximizing yield and profitability in the mining industry. Bunting’s advanced magnetic and electrostatic separation solutions are engineered to recover valuable minerals.

Laboratory Sample Testing Service

To ensure the best separation results, Bunting offers a fully equipped material testing laboratory to help determine the ideal equipment for each application. Customers are welcome to send in samples for testing and evaluation, allowing us to measure separation performance and provide detailed results along with our equipment recommendations.

Mineral Processing Applications

Bunting supports various sectors with tailored solutions:

Magnetic separators extract magnetite and other magnetic minerals, producing high-grade ore concentrates efficiently.

Remove iron mineral contaminants from quartz, feldspar, and silica sand to enhance product purity.

Separate valuable minerals like ilmenite, monazite and zircon from sands, maximizing recovery and product value.

Eliminate ferrous metals from coal to improve quality and protect processing equipment.

Efficiently recover critical minerals from feedstocks such as lithium and rare earth minerals.

High-intensity separators remove weakly magnetic impurities from minerals like kaolin and magnesite.

Specialized separators concentrate valuable minerals such as improving recovery of chrome and tungsten.

Electromagnetic filters remove fine iron particles from kaolin and calcium carbonate slurries, ensuring high material purity.

Recover metals and remove contaminants from recycled mineral streams to support sustainability.

Mineral Processing Equipment

-

All

-

Magnetic Separation

-

Electromagnetic Filters

Replaces standard head pulleys to continuously remove tramp ferrous metals from conveyors.

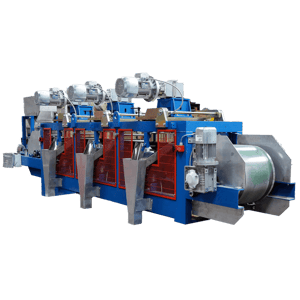

Continuously separates and discharges ferrous metals for automated, high-volume processing.

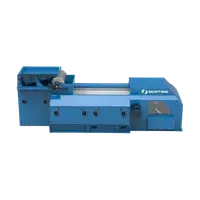

Separates weakly magnetic minerals, like garnet or ilmenite, from non-magnetic materials.

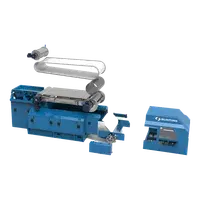

Delivers high-precision separation of weakly magnetic materials using powerful induced magnetic forces.

Separates weakly magnetic minerals from non-magnetic material using high-intensity rotating discs.

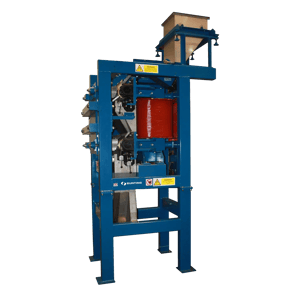

Removes fine ferrous contaminants from wet and dry products with high-strength magnetic fields.

Mechanical separation method using differences in electrical conductivity to efficiently separate a wide range of materials.

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.