Magnetic Disc Separator

| Industries | Minerals, Recycling, Mining |

| Magnet | Electromagnetic |

| Strength | Up to 20,000 Gauss (adjustable) |

| Material | Dry |

| Separates | Mineral beach sands, tin tungsten, black mass processing, gold recovery from e-waste |

Options / Features

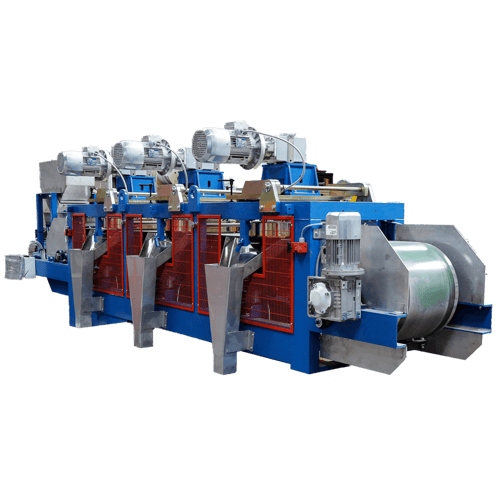

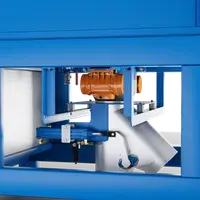

Up to three electromagnetic discs for precise separation of minerals by magnetic susceptibility.

One pair of coils per disc for tailored magnetic intensity and enhanced separation efficiency.

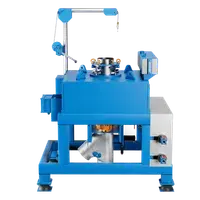

Laboratory-scale separator for controlled testing and customized separation solutions.

Animation

- About

- Benefits

- Tech Specs

The Magnetic Disc Separator is a highly effective solution for separating minerals based on their magnetic susceptibility. Utilizing advanced electromagnetic technology, this separator is designed to process a variety of materials, including granular minerals and waste products, to improve purity and recovery rates.

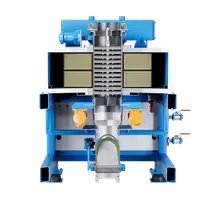

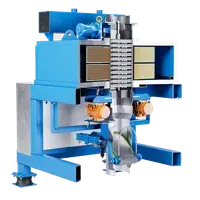

The separator features up to three high-intensity electromagnetic discs, each is infinitely adjustable between 1,000 and 20,000 Gauss. This design allows for precise separation of various grades of magnetic materials, making it suitable for applications in industries such as ceramics, glass manufacturing, and recycling.

Bunting is dedicated to providing high-quality equipment that meets industry standards. The Magnetic Disc Separator is built to withstand demanding industrial environments while delivering reliable performance. We also offer laboratory-scale models for testing and validation, allowing clients to optimize their processes before full-scale implementation.

With a focus on customer satisfaction and sustainable practices, Bunting’s Magnetic Disc Separator addresses the evolving needs of the market while supporting efficient resource recovery and minimizing waste. Whether you aim to enhance mineral purity or improve operational efficiency, our Magnetic Disc Separator is designed to meet your separation requirements effectively.

Precision Separation: The Magnetic Disc Separator utilizes advanced electromagnetic technology to separate minerals based on their magnetic susceptibilities accurately, ensuring high purity and recovery rates.

Optimized Performance: With up to three adjustable electromagnetic discs, this separator allows for tailored separation processes that can be fine-tuned to meet specific material characteristics.

Robust Design: Built with durable materials, the Magnetic Disc Separator is designed to withstand demanding industrial environments, ensuring long-lasting performance and reliability.

Laboratory Testing Support: Bunting provides access to a laboratory-scale separator for controlled testing, enabling clients to validate separation parameters before full-scale implementation.

Versatile Applications: Suitable for a wide range of mineral processing applications, including the separation of beach sands, coltan recovery, and quartz purification, making it a versatile solution for various industries.

Magnet Type

Electromagnet

Magnetic Strength

Up to 20,000 Gauss

Materials Handled

Dry, granular minerals

Separation Targets

Paramagnetic and weakly magnetic materials and minerals

Industries

Minerals, Recycling, Mining

Typical Configuration

Typically supplied with three discs, each adjustable to different heights, allowing the machine to produce up to seven separate material streams in a single pass.

Feed Size

Up to 2mm (0.08")

Capacity

600 kg/hr (1300 lbs/hr) depending on material

Features

Adjustable magnetic field strength for each disc half

Variable disc speed

Adjustable disc height and angle relative to the conveyor belt

Electro feeder for controlled material flow

Application Photos

Want To Know More?

Contact one of our sales representatives to discuss your specific needs and interests.