Plastics Recycling

Magnetic Separation, Metal Detection, and Conveyors

Increase Profit Through Cleaner Plastic and Consistent Output

In plastics recycling, profit is driven by material quality and consistency. Contamination lowers yield, creates rejects, and puts finished material at risk of missing buyer specifications. Even small amounts of metal can disrupt processing, lead to scrap, and reduce the value of every pound produced.

Bunting designs magnetic separation, metal detection, and conveying systems to help plastics recyclers deliver cleaner material, tighter consistency, and reliable output. By removing metal before it reaches critical processing stages, our systems help protect grinders, extruders, and pelletizers, preventing unplanned downtime that interrupts production and impacts margins.

Cleaner plastic means higher yield, fewer rejects, and stronger pricing from buyers.

Our equipment removes ferrous and non-ferrous metal from flakes, regrind, pellets, and mixed material streams early and consistently. This reduces scrap, limits rework, and helps maintain stable processing conditions so lines run predictably shift after shift and finished material stays within specification.

Every system is engineered to fit into existing processing lines with minimal disruption. The result is consistent quality, improved uptime, and plastics recycling operations that perform reliably, keeping material moving and profit intact.

Solutions

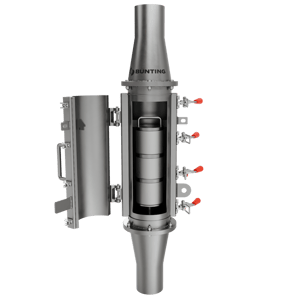

Magnetic separation plays a critical role in protecting material quality and maintaining stable plastics recycling operations.

Bunting magnetic separators remove ferrous contamination from material streams before metal can compromise consistency or damage downstream equipment. Early removal helps protect grinders and extrusion systems, reducing unplanned stoppages that lead to scrap and lost production. Cleaner material supports higher yield, fewer rejects, and more predictable output.

Metal detection provides the final safeguard for material quality and line stability.

Bunting metal detectors identify and reject non-magnetic metals such as stainless steel and aluminum that pass beyond magnetic separation. Installed in gravity-fed, pneumatic, and conveyor applications, these systems help prevent off-spec material and reduce the risk of metal events that can shut down extrusion or pelletizing lines.

Consistent material flow supports consistent quality.

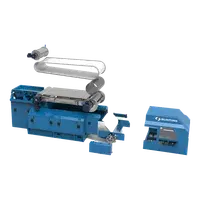

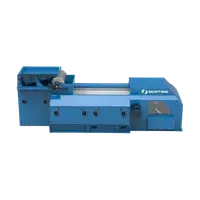

Bunting conveyors are designed to move material steadily through plastics recycling lines without introducing variation or disruption. Controlled flow helps maintain stable processing conditions, reduces handling issues, and supports consistent separation and detection, keeping lines running smoothly and material quality intact.

Industries Served

Post-consumer streams bring wide variation and high risk of contamination. Bunting systems help recyclers remove metal early in the process, improving consistency across washed and processed material. Cleaner output reduces rejects, stabilizes downstream processing, and supports tighter quality standards required by buyers.

Post-industrial scrap offers strong margin potential, but only when quality is protected. Bunting magnetic separation and metal detection systems help maintain clean material streams, preserving yield and reducing the risk of off-spec production. The result is predictable quality and less material loss during processing.

Metal contamination in regrind and flake leads to scrap, rework, and inconsistent output. Bunting systems remove ferrous and non-ferrous metal before it can affect size, appearance, or melt consistency. This helps recyclers maintain tighter control over finished material and improve usable yield.

Pellet and compound buyers demand consistency. Even small metal contamination can result in rejected batches. Bunting solutions help recyclers maintain clean material throughout the process, reducing scrap, avoiding quality issues, and supporting repeatable, spec-compliant production.

Mixed plastic streams increase contamination risk and quality variation. Bunting systems help recyclers control metal contamination across film, rigid, and blended materials, improving consistency through washing, grinding, and extrusion. Cleaner streams mean fewer interruptions and more reliable finished product.

Sorting and wash lines set the foundation for material quality. Bunting equipment removes metal contamination at key transfer points, helping protect consistency through the wash process. Stable material flow and cleaner output reduce downstream issues and support higher-quality finished plastic.

Recycling Equipment

-

All

-

Magnetic Separation

-

Metal Detection

-

Material Handling

Continuously remove ferrous metal from conveyed material.

Keeps product streams clean without stopping flow.

Remove ferrous metal from bulk material using overhead separation. Supports clean output in continuous operations.

Automatically separate ferrous metal from bulk material. Delivers consistent, high-volume separation.

Remove ferrous metal at the conveyor discharge point. Provides continuous contamination control.

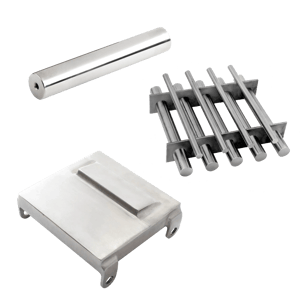

Capture ferrous contamination from dry, free-flowing material. Helps maintain clean, consistent output.

Remove ferrous metal from gravity-fed or pneumatic lines. Maintains flow while controlling contamination.

Remove ferrous contaminants from dry, free-flowing materials using stationary magnetic elements that fit easily into chutes, hoppers, and gravity flow systems.

Detect and reject metal in free-falling material.

Helps prevent off-spec output and reduce scrap.

Detect metal in pneumatically conveyed material. Maintains quality without disrupting airflow.

Detect ferrous, non-ferrous, and stainless steel contamination. Supports consistent quality on moving material.

Move material through the process with steady, controlled flow. Supports consistent quality and stable operation.

Separate mixed plastics by polymer type after washing and drying. Improves material purity and buyer acceptance.

Talk to an Application Engineer

Need to remove metal from shredded scrap, recycled plastic, municipal waste, or ground tire rubber? Our experts will help you select the right magnetic separator or metal detector to protect your equipment, improve material purity, and keep your recycling line running efficiently.

FAQ's

Even small amounts of metal can disrupt processing, create defects, and cause off-spec material. Contamination leads to scrap, reprocessing, and lost value, especially in regrind, flake, and pellet production.