Conveyor Metal Detectors

Conveyor metal detectors from Bunting are engineered to detect ferrous, non-ferrous, stainless steel, and manganese steel contaminants in a wide range of conveyed materials. Available in one-piece (closed coil), two-piece (devisable coil), and under-belt configurations, these systems serve critical roles in food processing, plastics processing, recycling, and heavy-duty bulk handling applications such as aggregate, mining, and minerals. Depending on the setup, detectors can be installed around the conveyor belt or directly beneath the belt to inspect product as it moves through the line.

By detecting metal contamination before it reaches crushers, extruders, packaging machines, or grinders, Bunting conveyor metal detectors help manufacturers avoid equipment damage, product recalls, and costly downtime. When paired with automatic reject mechanisms or used in combination with magnetic separation equipment, they provide a comprehensive metal control solution. Whether protecting a food brand or preventing tramp metal from destroying quarry equipment, these detectors deliver peace of mind, operational efficiency, and long-term cost savings.

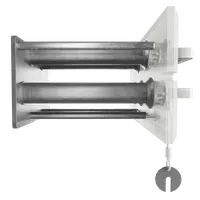

One-Piece Tunnel Style Metal Detectors

Applications

Food processing, packaging, and ingredient handling

Materials Handled

Packaged and unpackaged products, frozen foods, baked goods, bulk powders, grains, spices, dairy, meats, and snacks

Benefits

- High-sensitivity detection of ferrous, non-ferrous, and stainless steel contaminants

- Hygienic one-piece design for easy cleaning and washdown compatibility

- Integrated system with digital signal processing for high-speed accuracy

- Supports HACCP, FSMA, FDA, USDA, and GFSI compliance

- Seamless integration with pushers, diverters, or air blast reject systems

- Low-maintenance operation with durable construction for 24/7 environments

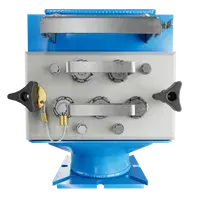

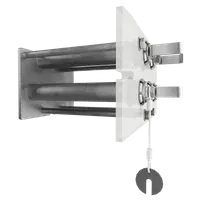

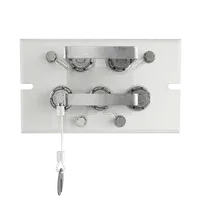

Two-Piece Tunnel Style Metal Detectors

Applications

Plastics processing, recycling, and general manufacturing

Materials Handled

Shredded plastic, granules, pellets, bulk fiber, and conveyed product on non-metallic belts

Benefits

- High-sensitivity detection of ferrous, non-ferrous, and stainless-steel contaminants

- Split-coil design enables installation around existing conveyors without cutting the belt

- Ideal for retrofitting inspection capabilities.

- Compatible with reject systems and integrates easily into automation environments

- Corrosion-resistant construction options for washdown or industrial settings

- Supports regulatory compliance and quality assurance programs across industries

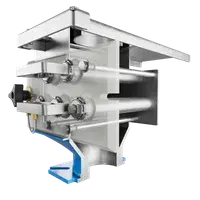

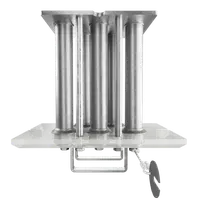

TN Series Metal Detectors

Applications

Quarrying, mining, mineral processing, and bulk material handling

Materials Handled

Sand, gravel, crushed stone, coal, limestone, gypsum, and bulk raw materials on non-metallic conveyor belts

Benefits

- Detection of ferrous metals and manganese steel contaminants

- Split-frame design enables easy installation around existing conveyors without cutting the belt

- Engineered to detect ferrous tramp metal such as drill bits, bucket teeth, and manganese crusher liners

- Prevents equipment damage and reduces downtime by stopping tramp metal before it reaches crushers or screens

- Weather-resistant construction built for harsh outdoor and dusty environments

- Reliable, low-maintenance operation in high-throughput, heavy-duty processing lines

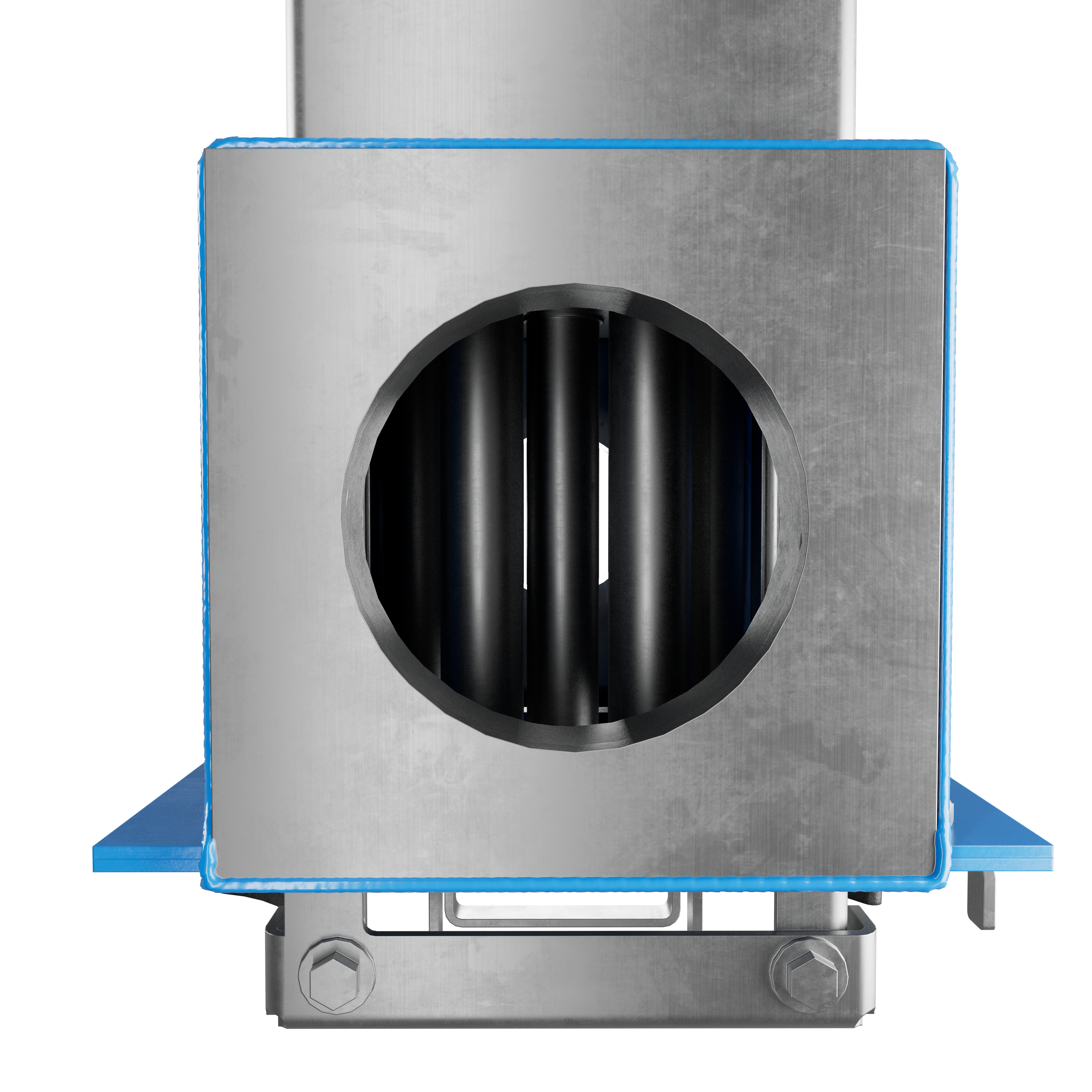

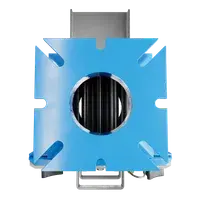

Under-Belt Metal Detectors

Applications

Mining, recycling, biomass, wood processing, glass, and bulk material handling

Materials Handled

Sand, gravel, coal, shredded plastics, biomass fuel, wood chips, cullet, raw silica, and other bulk conveyed materials

Benefits

- Installs beneath non-metallic conveyors to detect tramp metal without disrupting material flow

- Detects ferrous, non-ferrous, and manganese steel contaminants

- Protects shredders, crushers, chippers, grinders, and downstream equipment from metal damage

- Reduces downtime, repair costs, and production losses across multiple industries

- Interfaces with alarms, marker systems, and stop-on-detect controls for rapid response

- Built for harsh, dusty environments with heavy-duty components and minimal maintenance

Metal Detector Conveyor

Applications

Food processing, packaging, and quality control

Materials Handled

Packaged and unpackaged food products, finished goods, and bulk items on conveyor belts

Benefits

- Integrated conveyor and metal detector system for seamless inspection and conveyance

- Detects ferrous, non-ferrous, and stainless-steel contaminants with high accuracy

- Available in a range of tunnel sizes, belt widths, and reject configurations to suit your line

- Built with stainless steel construction and sanitary design for food-grade environments

- Simplifies installation with plug-and-play operation—no separate integration required

- Improves product safety, reduces recalls, and supports regulatory compliance (FDA, USDA, CE)

- Designed for 24/7 production with minimal maintenance and reliable performance

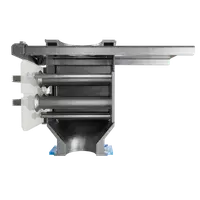

Feeder-Discharge Conveyor w/ Metal Detector

Applications

Plastics recycling, shredding, granulating, and extrusion operations

Materials Handled

Shredded plastic, scrap material, regrind, and recycled plastics prior to size reduction or extrusion

Benefits

- Detects and removes ferrous, non-ferrous, and stainless-steel contaminants before material enters shredders, granulators, or extruders

- Prevents equipment damage by stopping metal before reaches shredders and granulators

- Maximizes product purity at both the shredder infeed and granulator discharge

- Integrated metal detector and conveyor solution designed to fit directly into recycling workflows

- Improves overall system efficiency by reducing downtime and minimizing costly repairs

- Available with custom paint and configuration options to match your shredder system and plant layout

Checkweigher

Applications

Food packaging, pharmaceuticals, nutritional products, and bulk goods

Materials Handled

Packaged foods, bottles, bags, cartons, sachets, powdered ingredients, and consumer goods

Benefits

- Combines high-accuracy weight inspection with metal detection in a single inline system

- Uses Electro-Magnetic Force Restoration (EMFR) for ultra-precise weight measurement

- Reduces product giveaway and ensures consistent portion control

- Supports regulatory compliance with full traceability and audit logging

- Handles up to 225 products per minute with minimal downtime

- Available with air blast, pusher arm, or dual-bin reject systems

- Built for wet, dry, or washdown environments with IP54, IP66, or IP69K options

- Configurable for diverse line layouts in food, pharma, and consumer goods applications

About

Bunting's Performer Series tunnel metal detectors provide advanced contamination detection for various applications, including food processing, pharmaceuticals, and manufacturing. Our reliable systems are designed to offer high-precision identification of ferrous, non-ferrous, and stainless steel contaminants, ensuring product purity and protecting valuable equipment.

These tunnel metal detectors feature customizable designs that can seamlessly integrate into existing production lines. They come equipped with user-friendly control panels for easy operation and advanced detection capabilities that deliver superior sensitivity. Optional waterproof and epoxy-filled search heads enhance durability, while efficient rejection systems minimize product loss.

Key Benefits of Implementing Bunting Tunnel Metal Detectors Include:

- Protecting product integrity and brand reputation

- Safeguarding downstream equipment from damage

- Ensuring compliance with industry standards and regulations

- Improving overall production efficiency

- Minimizing costly downtime and repairs

Our systems can detect ferrous metal particles as small as 1.75-2.0mm, non-ferrous metals at 2.0-2.5mm, and stainless steel at 2.5-3.0mm, making them ideal for industries requiring the highest level of detection.

Enhance your quality control process with Bunting's reliable and efficient tunnel metal detectors. Contact us today for a customized solution tailored to your specific needs!

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.