Food & Pharma

Magnetic Separation and Metal Detection for Food & Pharmaceutical Processing

Protect Product Integrity. Safeguard Patient Safety. Meet Regulatory Requirements.

Bunting designs and manufactures high-performance metal detection and magnetic separation systems for the food and pharmaceutical industries. With over 60 years of expertise, we help you remove metal contaminants, prevent recalls, comply with safety standards, and protect your brand—and your customers.

The Critical Cost of Metal Contamination

In Food Processing: A Threat to Consumer Trust and Safety

Metal fragments can enter the product flow from machinery wear, broken parts, or packaging damage. Contaminants pose a risk of choking, internal injury, or dental damage.

Without proper detection and removal systems, contamination can lead to:

- Costly Class II recalls

- Product liability lawsuits

- Damage to brand reputation

- Disruption of supply chains

In Pharmaceutical Manufacturing: Zero Tolerance, Zero Margin for Error

Pharma regulations are strict—and noncompliance is expensive. According to CFR Title 21 §211.67, equipment must be maintained to prevent contamination that could alter a drug’s safety, identity, strength, or purity.

Metal contamination in pills, powders, or capsules can result in: facility shutdowns, regulatory investigations, loss of licenses or certifications, patient safety risks, long-term brand erosion

The European Medicines Agency (EMA) requires justification for the absence of metal detection. In most facilities, detection is now considered mandatory.

Industries Served

We offer solutions for a wide range of food processing industries, including:

Bunting equipment is trusted across every segment of the food industry to prevent metal contamination during bulk handling, mixing, processing, and packaging. We support:

- Dairy Processing: Milk powders, cheeses, yogurts, and frozen dairy products

- Meat & Poultry: Ground meat, sausage, cooked products, and ready-to-eat meals

- Grains & Cereals: Flour, rice, corn, oats, wheat, and processed grain mixes

- Snack Foods: Chips, crackers, granola, nuts, seeds, trail mixes, popcorn

- Sauces & Condiments: Tomato-based products, dressings, dips, and purees

- Beverage Production: Juices, flavored waters, syrups, alcohol, and concentrates

Metal contamination can affect product purity and lead to failed batch testing in nutraceutical manufacturing. Bunting helps protect:

- Protein & Meal Replacements: Whey, soy, pea, collagen, and powdered blends

- Dietary Supplements: Capsules, tablets, powders, and gummies

- Herbal & Vitamin Products: Botanicals, multivitamins, immune blends

Pharmaceutical facilities require zero-tolerance metal control. Bunting systems are engineered for cGMP environments and support:

- Tablet and Capsule Production: Metal detection before and after tableting

- Powder Handling: Bulk APIs, excipients, and fine powders

- Liquid Pharmaceutical Processing: Injectable drugs, oral solutions, sterile suspensions

- Packaging Lines: Bottle, blister pack, and sachet inspection and quality control

Animal feed must meet safety standards to prevent harm to livestock and pets. Bunting helps manufacturers comply with FSMA and AFIA standards:

- Dry Kibble and Treats: For dogs, cats, and small animals

- Wet and Canned Foods: Including gravies, pâtés, and stews

- Feed and Meal for Livestock: Poultry, swine, cattle, equine, and aquaculture feeds

- Supplement Blends: Mineral mixes, vitamins, and performance nutrition

Food Processing Equipment

-

All

-

Magnetic Separation

-

Metal Detection

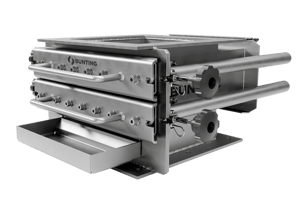

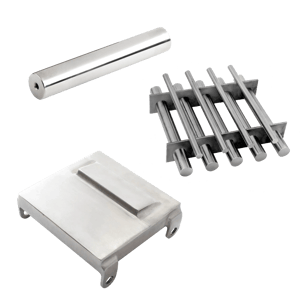

Capture and retain ferrous contaminants from gravity-fed powders and pellets to protect equipment and ensure product purity.

Continuously separates and discharges ferrous metals for automated, high-volume processing.

Captures ferrous contaminants in pneumatic and gravity-fed systems without slowing flow.

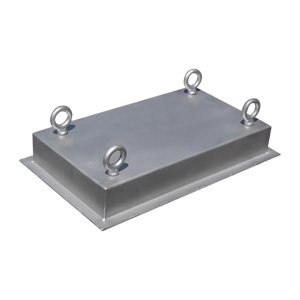

Removes tramp ferrous metals from conveyed bulk materials using overhead magnetic separation.

Removes ferrous particles from liquids and slurries, ensuring purity and preventing contamination.

Removes tramp ferrous metals from gravity-fed product flow without disrupting throughput.

Remove ferrous contaminants from dry, free-flowing materials using stationary magnetic elements that fit easily into chutes, hoppers, and gravity flow systems.

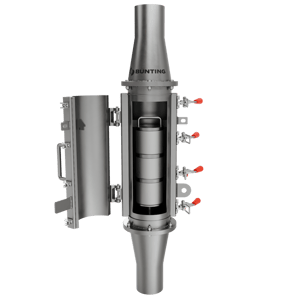

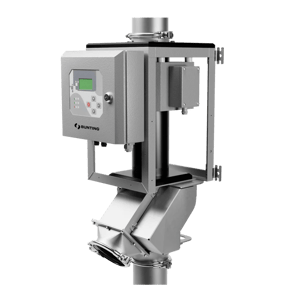

Used where products fall freely by gravity through a detection coil, these detectors are ideal for inspecting granules, powders, and pellets.

Detects and removes metal contaminants from liquid, slurries, pastes and meat in pumped product streams. Custom-designed to fit any pipeline application.

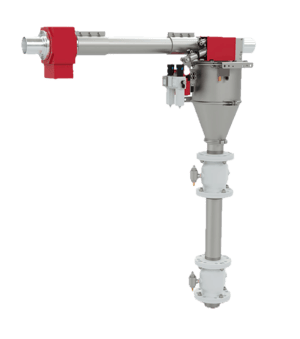

Remove metal contaminants from powders, granules, and pellets in vacuum or pressure pneumatic lines. Ideal for plastics, chemical, and food processing.

Provide high-sensitivity inspection for food, plastics, recycling, and manufacturing. Available in one-piece and two-piece designs for easy integration.

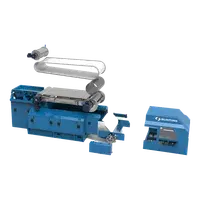

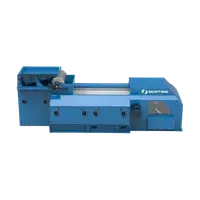

Integrated conveyor and metal detection systems for the food industry. Detect ferrous, non-ferrous, and stainless steel contaminants to protect products, equipment, and brand integrity.

Frequently Asked Questions

Bunting systems detect and/or remove ferrous metals (iron and steel), non-ferrous metals (aluminum, brass, copper), and stainless steel—even when embedded inside product or concealed in packaging. Our high-intensity magnets and advanced metal detectors identify small particles.

Our sanitary-grade magnetic separation and metal detection systems are built to meet or exceed:

- USDA/AMS Meat and Poultry Accepted Equipment criteria

- FDA and FSMA regulations

- 3-A Sanitary Standards

- GFSI and HACCP compliance

We also manufacture food-safe and utility-grade equipment for non-contact bulk applications.

In most food and pharma applications, yes. Magnetic separation removes ferrous metal at high volumes early in the process. Metal detectors then catch non-magnetic metals or stainless steel downstream. Together, they create a layered defense to ensure product purity and equipment protection.

Yes. We offer equipment specifically designed for pharmaceutical cleanroom environments, including:

- Compact, sanitary metal detectors for tablets and capsules

- Magnetic separation for bulk powders, excipients, and APIs

- Designs that meet cGMP and CFR Title 21 §211.67 equipment maintenance standards

Absolutely. We offer sanitary-grade equipment (BMC 300) with:

- 316 stainless steel construction

- Electropolished finishes

- Tool-free cleaning and removal

- FDA-approved gaskets and seals

These designs are ideal for direct contact with food or pharmaceutical product streams.

Typical sources include:

- Machinery wear (screens, blades, mixers, conveyor parts)

- Dropped tools or fasteners during maintenance

- Packaging line breakdowns (twist ties, foil, staples)

- Raw material contamination from suppliers

Bunting systems help eliminate these threats before they reach your customers.

Yes. We offer free product testing in our on-site applications lab. Send us your material, and we’ll simulate real-world separation and detection to recommend the best solution.

Talk to an Application Engineer

Processing flour, spices, dairy powders, or frozen foods? Our experts will help you select the right magnetic separator or metal detector to keep your line safe and your product contaminant-free.