Metal Recycling Equipment

Maximizing metal recovery and enhancing recycling efficiency with advanced magnetic separation and detection technologies

Bunting offers magnetic separation, metal detection, and material handling equipment tailored to the metal recycling industry. Our solutions maximize metal recovery, improve material purity, and enhance profitability across a wide range of applications.

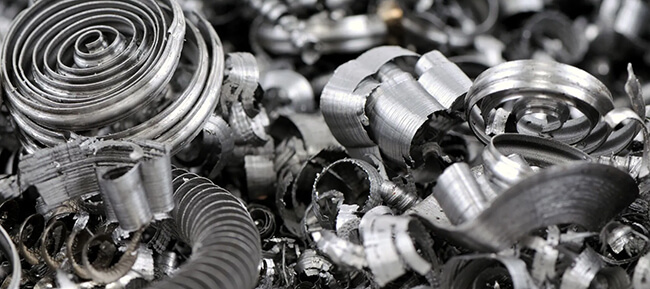

Efficient separation is key to profitability in metal recycling. Bunting's advanced magnetic separators and metal detectors precisely identify and extract valuable metals from mixed scrap streams. Our equipment ensures high-purity output, maximizing recovery rates and boosting revenue for recycling operations.

Total Metal Separation Solutions

We provide a comprehensive suite of solutions for efficiently separating and recovering valuable metals from diverse scrap sources, including end-of-life vehicles, industrial waste, and electronic scrap. Our advanced technologies maximize metal recovery rates, enhance material purity, and optimize profitability in metal recycling operations.

Metal Recycling Applications

Bunting supports various metal recycling sectors with tailored solutions:

Efficiently separate ferrous, non-ferrous, and stainless steel components from end-of-life vehicles.

Recover precious and base metals from discarded electronics while removing hazardous materials.

Process and sort mixed metal waste from manufacturing and construction industries.

Efficiently separate and recover various metals from community recycling programs.

Maximize metal recovery from auto shredder residue (ASR) and other shredded waste streams.

Metal Recycling Equipment

-

All

-

Magnetic Separation

-

Material Handling

Durable and reliable, these magnets remove large ferrous contaminants from high-volume waste streams.

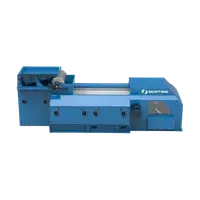

Ideal for continuous separation of ferrous metals from bulk materials in recycling facilities.

Replace standard conveyor pulleys to provide effective ferrous metal separation without additional equipment.

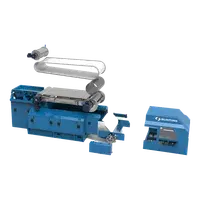

For recovering non-ferrous metals like aluminum and copper from mixed waste streams, maximizing resource recovery and boosting profits.

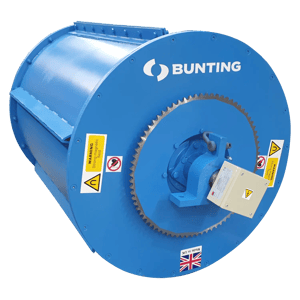

High-intensity magnetic technology designed to recover stainless steel and weakly magnetic materials from waste streams.

Streamline plastic processing operations by efficiently transporting materials between production stages.

Expert Support at Your Service

At Bunting, we understand that selecting the right magnetic separation solution can be a complex decision. That’s why our team of experienced professionals is here to assist you every step of the way.