Plastics Processing

Magnetic Separation | Metal Detectors | Conveyors

Magnetic Separation, Metal Detection & Conveyors for Plastics Processing

Remove Contaminants. Protect Equipment. Keep Production Moving.

From pellet to part, Bunting delivers integrated systems to detect, separate, and eliminate metal contamination in plastics processing environments. Whether you're working with virgin resins or engineered compounds, our solutions protect your line from metal that can damage tooling, cause product defects, or bring production to a halt.

Our systems are used in injection molding, extrusion, blow molding, and recycling operations to:

- Remove ferrous and non-ferrous metal contamination

- Protect critical equipment like extruders, granulators, shredders, and molding machines.

- Ensure consistent product quality and compliance

- Minimize downtime, maintenance, and scrap

- Streamline material flow between every stage of production

Safeguarding Equipment and Enhancing Product Purity

Metal contamination in plastic processing can lead to costly equipment damage, production downtime, and compromised product quality. Bunting's magnetic separators and metal detectors are engineered to identify and remove ferrous, non-ferrous, and stainless steel contaminants, ensuring the longevity of your equipment and the integrity of your products.

Total Metal Separation Solutions

We offer a total solution approach to removing problematic and damaging metal contamination from a diverse range of plastic material such as plastic flake, shredded plastic waste, plastic bottles and many more.

Solutions

Our powerful magnetic separators remove ferrous metals—such as steel fines, wire, or bolts—from plastic granules, powders, regrind, and flakes. These systems are strategically installed at feed throats, hoppers, and conveyors to protect your most valuable assets from contamination-related damage.

For non-magnetic threats like aluminum, brass, and stainless steel, our high-sensitivity metal detectors identify and reject contaminants in real-time. Designed for gravity, pneumatic, and conveyor systems, these detectors deliver protection with minimal material loss—even in abrasive, recycled, or dusty conditions.

Our conveyors move raw materials, in-process scrap, and finished plastic parts efficiently while incorporating separation and detection technologies. Engineered for reliability, they prevent contamination from spreading downstream and can be tailored to fit seamlessly into your workflow—reducing manual handling and improving throughput.

Industries Served

Magnetic separators and metal detectors protect injection molding equipment from metal particles that could cause damage, ensuring the production of high-quality plastic parts and extending the lifespan of expensive machinery.

Both magnetic separators and metal detectors are crucial in recycling facilities to remove metal contaminants from recycled materials like PET bottles, LDPE and HDPE films, PET-flakes, and shredded PVC

Metal detection and separation are used throughout the production process to ensure product purity and protect equipment, from raw material intake to final product packaging, maintaining consistent quality standards.

Metal detectors and magnetic separators are employed to purify plastic pellets before distribution. These technologies effectively remove metal contaminants, ensuring the quality of raw materials for downstream plastic manufacturing processes, protecting equipment, and maintaining the integrity of final plastic products.

Metal detection and magnetic separation is used in the manufacturing of plastic films to remove contaminants, ensuring the production of high-quality, defect-free films for various applications such as packaging and construction.

Plastic Processing Equipment

-

All

-

Magnetic Separation

-

Metal Detection

-

Material Handling

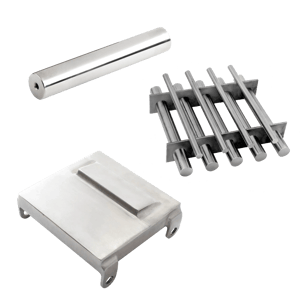

Capture and retain ferrous contaminants from gravity-fed powders and pellets to protect equipment and ensure product purity.

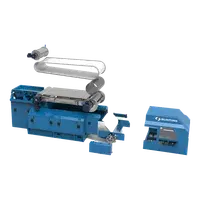

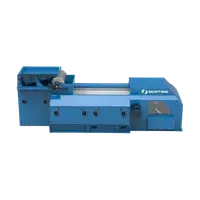

Continuously separates and discharges ferrous metals for automated, high-volume processing.

/PIM-4-NE-F_sm0008.png?width=300&name=PIM-4-NE-F_sm0008.png)

Captures ferrous contaminants in pneumatic and gravity-fed systems without slowing flow.

Replaces standard head pulleys to continuously remove tramp ferrous metals from conveyors.

Remove ferrous contaminants from dry, free-flowing materials using stationary magnetic elements that fit easily into chutes, hoppers, and gravity flow systems.

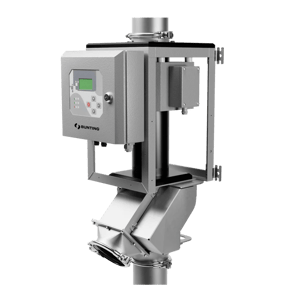

Used where products fall freely by gravity through a detection coil, these detectors are ideal for inspecting granules, powders, and pellets in plastics and food processing applications.

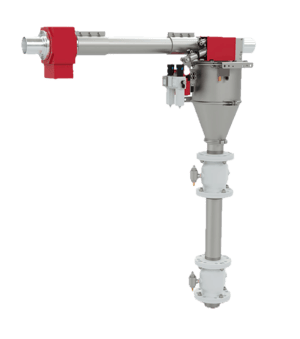

Remove metal contaminants from powders, granules, and pellets in vacuum or pressure pneumatic lines. Ideal for plastics, chemical, and food processing.

One-piece and two-piece tunnel, and under-belt configurations to detect ferrous, non-ferrous, and stainless steel contaminants in food, plastics & recycling.

Streamline plastic processing operations by efficiently transporting materials between production stages.

FAQ's

By combining detection, separation, and conveying, Bunting provides plastics manufacturers and recyclers with complete, contamination-free material handling systems—all built to withstand demanding production environments.

Talk to an Application Engineer

Dealing with virgin resin, colorant, or regrind? Our experts will help you choose the right magnetic separator or metal detector to protect your molding or extrusion line.