Electromagnetic Wet Filter

| Magnet | Electromagnet |

| Strength | Up to 10,000 gauss (background field) |

| Material | Slurries and Liquids |

| Separates | Fine Iron, Paramagnetic Minerals |

Options / Features

.gif?width=300&name=bun_heimfilter_craneanimation_240424_v07%2B(1080p).gif)

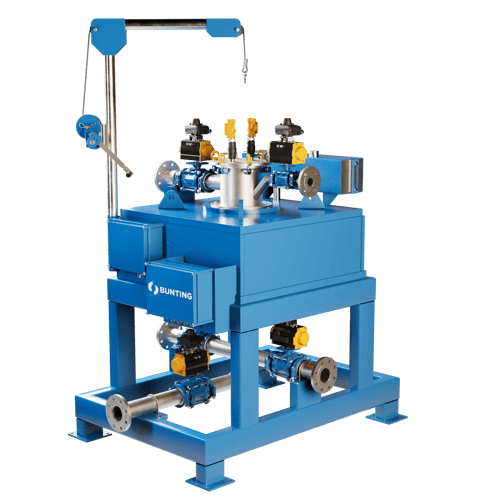

Includes a removable jib crane for easy removal of the top pole and matrix assembly for maintenance and cleanings.

%2B(1).gif?width=300&name=bun_heimfilter_airgraphics_240530_v02%2B(1080p)%2B(1).gif)

Automated back flush cleaning cycle to clean captured contaminants off the matrix.

Animations

Cleaning

Electromagnetic Removal

- About

- Benefits

- Tech Specs

- Capacity

- Drawings

Electromagnetic Filters: Powerful Magnetic Separation Technology

Electromagnetic filters provide highly effective removal of fine iron and paramagnetic minerals from ceramic slips, glazes, and industrial mineral slurries. Key features include:

- Generates background magnetic fields up to 10,000 Gauss, amplified 3–4 times on the matrix for higher separation efficiency

- Remove problematic magnetic particles as small as 0-500 microns

- Automated cleaning cycles for continuous processing

How Electromagnetic Filters Work

- Electromagnetic coil induces an intense magnetic field onto the matrix

- Slurry pumped through matrix, magnetic particles attracted and captured

- Periodic cleaning cycles flush out captured particles

- Can be set up in pairs for non-stop operation

Key Benefits

- More effective than permanent magnetic separators

- Removes very fine iron and paramagnetic minerals

- Improves purity of ceramic materials and industrial minerals

- Automated operation with programmable controls

Common Applications

- Cleaning ceramic glazes and slips

- Purifying mineral slurries like silica sand, feldspar, kaolin, etc.

- Removing contaminants from ball clay, calcium carbonate, talc

For industries requiring high-purity materials, electromagnetic filters offer powerful magnetic separation capabilities to remove even the finest magnetic contaminants. Their adjustable field strength and automated operation make them ideal for a wide range of ceramic and mineral processing applications.

High Magnetic Field Strength: Offers a range of background magnetic field strengths from 3,500 to 10,000 gauss for effective separation of fine iron and paramagnetic minerals from liquids and slurries.

Applications: Used to remove fine iron and paramagnetic minerals from non-metallic mineral slurries.

Efficient Separation: Higher separation efficiency than permanent magnetic separators by generating significant background magnetic field strength, and a high-magnetic field gradient on the matrix surface.

Back Flush Cleaning: Automated back flush cleaning cycle to clean captured contaminants off the matrix. Cycle times can be adjusted via the HMI to suit application needs.

Energy Efficiency: Utilizes highly efficient computer-designed coils paired with a water over oil heat exchange to maintain optimal operating temperature.

Easy Maintenance: Includes a removable job crane for easy removal of the top pole and matrix assembly for maintenance and cleanings. This minimizes downtime and needs for additional infrastructure.

Controlled Operation: Can be fully automated using a control system with a Siemens S7-1200 PLC and HMI for managing cleaning frequency and parameters.

Valve Configurations: Available in 4-valve to 8-valve configurations to suit different applications.

Testing Facilities: Bunting offers controlled tests on laboratory-sized filters to confirm separation capabilities.

Magnet Type

Electromagnet

Magnetic Strength

Up to 10,000 Gauss background field (3-4 times higher on matrix surface)

Materials Handled

Slurries and liquids

Separation Targets

Fine iron particles, paramagnetic minerals, magnetic contaminants

Industries

Ceramics, battery manufacturing, recycling, mineral processing

Construction

Coil: Circular or rectangular steel casing

Wetted surfaces: 300-series stainless steel

Matrix: 400-series (magnetic) stainless steel

Matrix Design

Expanded metal mesh discs, sized to suit application

Control System

Siemens S7-1200 PLC with HMI (other options available)

Cleaning Mechanism

Manual or fully automated with programmable cleaning cycles

Optional Features

Adjustable magnetic field strength

Custom inlet/outlet configurations

Built-in jib for easy matrix removal and maintenance

Performance

Capable of removing very weakly magnetic particles untouched by other magnetic separation technologies

Customization

Available in various sizes and configurations to suit specific application requirements

*All capacities are dependent on the solid content

Fill out the form below and the drawings will be emailed to you.

Application Photos

Application Photos

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.