Get Metal Out

The global supplier of magnetic separation, metal detection, & conveyors.

Magnetic Solutions Trusted Around

the World

Featured Products

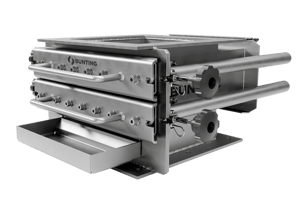

An air-cooled electromagnetic separator. Less weight, small footprint, enhanced metal separation.

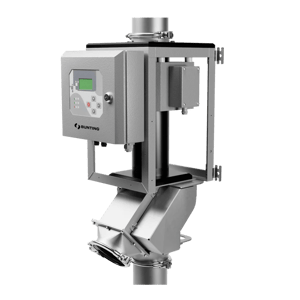

Detect ferrous, non-ferrous, and stainless-steel contaminants in gravity fall applications.

Feed material into shredders and remove it after processing with or without metal detectors.

Your Global Supplier of Magnetic Technology Solutions

For over 60 years, we've been at the forefront of innovation, designing and manufacturing solutions that serves a diverse range of industries. From food processing to recycling, mining to pharmaceuticals, our comprehensive lineup of magnetic separators, metal detectors, and conveyors enhances product purity, protects valuable machinery, and optimizes operational efficiency.

At Bunting, our experienced in-house engineering team uses advanced computer-aided design tools to develop custom solutions—when needed—that solve real-world problems and integrate seamlessly into your existing systems. Whether you're safeguarding a food line or protecting crushers in a quarry, our engineering expertise ensures your equipment performs with precision and reliability.

We’re committed to delivering standard and tailored solutions that meet your unique challenges, ensuring safety, quality, and profitability across your entire production process. Discover how our magnetic expertise, and our engineering strength, can revolutionize your industry today.

We Are Here to Help

Contact us to speak with a customer care representative for support, or connect with an application engineer to discuss your specific requirements.