Metal Detection

Metal Detection Products

-

All

-

Food & Pharma

-

Recycling

-

Plastics

-

Powder & Bulk

-

Aggregate & Mining

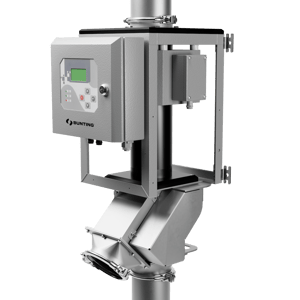

Used where products fall freely by gravity through a detection coil, these detectors are ideal for inspecting granules, powders, and pellets in plastics and food processing applications.

Remove metal contaminants from powders, granules, and pellets in vacuum or pressure pneumatic lines. Ideal for plastics, chemical, and food processing.

Provide high-sensitivity inspection for food, plastics, recycling, and manufacturing. Available in one-piece and two-piece designs for easy integration.

Installed beneath conveyors, these detectors continuously inspect bulk materials and detect tramp metal before it damages crushers, shredders, or grinders.

Detects and removes metal contaminants from liquid, slurries, pastes and meat in pumped product streams. Custom-designed to fit any pipeline application.

Detect ferrous and manganese steel tramp metal from conveyed materials. The TN Series protects crushers, screens, and belts in mining and quarrying.

Integrated conveyor and metal detection systems for the food industry. Detect ferrous, non-ferrous, and stainless steel contaminants to protect products, equipment, and brand integrity.

High-sensitivity inspection systems for film, foil, paper, and textile production. Detect metal contaminants, prevent damage, and ensure consistent quality.

Uncompromising Quality Control

Bunting supports various plastic recycling sectors with tailored solutions:

Optimize production efficiency, enabling higher output and reducing manufacturing interruptions.

Prevent product recalls, reduce waste, and minimize false rejects with precision metal detection technology.

Ensure product purity and consumer safety by detecting microscopic metal contaminants before distribution.

Why Choose Bunting's Performer Metal Detectors?

Animation

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.