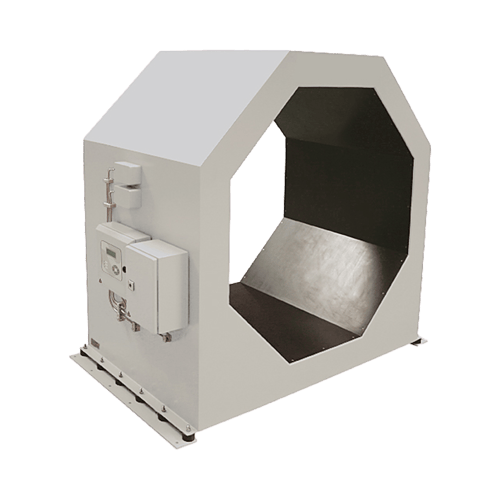

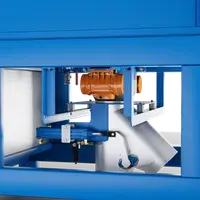

Performer Pro LO

Tunnel Metal Detector

The Performer Pro LO is a specialized octagonal tunnel metal detector engineered for comprehensive tree trunk examination. Designed to integrate seamlessly within logging and timber processing operations, this detector provides precise metal contamination screening for logs before and after debarking.

Options / Features

Engineered specifically for log and timber processing, enabling precise metal contamination detection.

Accommodates log diameters up to 80 inches (2000 mm)

Built to withstand harsh logging and timber processing environments, ensuring long-term reliability

Animation

- About

- Benefits

- Tech Specs

The Performer Pro LO is an octagonal tunnel metal detector designed for comprehensive log examination in timber processing operations. Engineered to integrate seamlessly with conveyor systems, this detector offers precise metal contamination screening across log sizes ranging from 35 inches to over 80 inches (890 mm to over 2000 mm).

Utilizing advanced detection technology, the Performer Pro LO identifies ferrous, non-ferrous, and stainless steel contaminants embedded within logs. This capability is crucial for protecting sawmill equipment from potential metal damage, ensuring operational efficiency and maintaining high product quality standards.

The detector's robust design enables consistent performance across diverse environments, from humid forest processing facilities to exposed outdoor logging sites. Its industrial-grade construction and digital signal processing technology provide reliable metal detection, while flexible installation options make it adaptable to various conveyor systems.

Key capabilities include digital signal processing, electromagnetic stability, and optional integration with color marking devices. By helping timber professionals reduce waste, protect expensive machinery, and maintain product integrity, the Performer Pro LO represents an essential tool in modern timber processing operations.

With its comprehensive approach to metal detection, the Performer Pro LO delivers a sophisticated solution for identifying and mitigating metal contamination risks in log processing, ultimately supporting more efficient and safer timber production practices.

Specialized Timber Protection: Designed specifically for log examination, preventing metal contamination in timber processing and safeguarding valuable sawmill equipment from damage.

Operational Efficiency: Seamlessly integrates into existing conveyor systems, allowing for efficient metal detection before and after debarking without disrupting production flow.

Versatile Log Handling: Accommodates a wide range of log sizes with its expansive diameter options, ensuring comprehensive metal detection across various timber dimensions.

Advanced Contaminant Identification: Precisely detects metal objects embedded in logs, including nails, wire fragments, and other foreign metallic materials, enhancing overall product quality.

Cost-Effective Processing: Minimizes potential financial losses by identifying metal contaminants early in the timber processing chain, reducing equipment damage and product waste.

Enhanced Safety Compliance: Supports adherence to industry safety standards and regulatory requirements, demonstrating commitment to worker safety and product integrity.

Robust Environmental Performance: Engineered to operate reliably in challenging logging and timber processing environments, ensuring consistent metal detection in various conditions.

Detection Capability

Detects ferrous, non-ferrous, and stainless steel contaminants in logs

Aperture Sizes

Octagonal design with diameters ranging upto 80 inches (2000 mm)

Customizable to specific timber processing requirements

Installation Options

Adaptable to various conveyor trough systems

Suitable for use before and after log debarking processes

Control Unit

Integrated electronic control panel with multiple detection modes

High-resolution iron discrimination with 40 levels

Construction

Robust design for harsh timber processing environments

Submersible up to 10 feet (3 meters)

Power Supply

Standard power supply (specific voltage requirements available upon request)

Long battery life for extended operation

Operating Temperature

Designed for outdoor use in various climatic conditions

Specific temperature range available upon request

Connectivity

Compatible with color marking devices and heavy-duty conveyors

Optional data logging and reporting features

Compliance

Meets industry safety standards for timber processing equipment

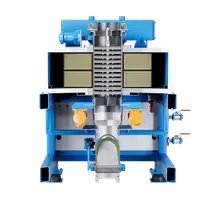

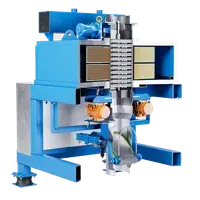

Application Photos

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.