ElectoMax Overband Magnets

| Material | Bulk materials, aggregates, recycled products, wood, biomass, and scrap |

| Separates | Ferrous tramp metal including iron, steel, and magnetic contaminants |

| Operation | Suspended electromagnetic separation with automatic metal discharge |

| Applications | Recycling, quarrying, mining, aggregates, wood processing, and bulk material handling |

Features

185% increased magnetic power than comparable permanent overband magnet.

25% less weight than comparable permanent overband magnet.

Optional heavy-duty belt resists damage from sharp, abrasive tramp metal.

Animation

- About

- Benefits

- Tech Specs

- Videos

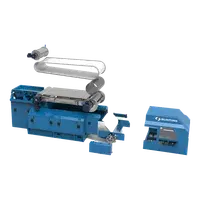

ElectroMax Overband Magnets are suspended electromagnetic separators engineered to extract ferrous tramp metal from bulk materials carried on conveyor belts. Positioned above the conveyor, they generate a controlled magnetic field that attracts ferrous contaminants from the conveyed product.

Once lifted from the material stream, captured metal is carried away from the magnetic field by a continuously running belt and discharged clear of the conveyor. This automatic discharge process allows tramp metal to be removed without stopping production or requiring manual intervention.

Designed for high-impact and high-volume applications, ElectroMax Overband Magnets are commonly used in recycling, quarrying, mining, and bulk material handling operations where tramp metal can cause equipment damage, downtime, or safety risks. Their robust construction and electromagnetic design make them well suited for harsh operating conditions.

Remove Ferrous Tramp Metal Automatically

Continuously extract iron and steel contaminants from conveyed materials without interrupting production.

Protect Downstream Equipment

Prevent tramp metal from damaging crushers, shredders, screens, grinders, and conveyors.

Provide Consistent Electromagnetic Separation

Electromagnetic design delivers reliable lifting force for ferrous metal removal in demanding applications.

Support Continuous Operation

Automatically discharge captured metal while the conveyor remains running.

Handle Harsh Operating Conditions

Designed for dusty, abrasive, and heavy-duty environments common in recycling and quarrying operations.

Help Reduce Downtime and Maintenance Costs

By removing tramp metal early in the process, systems experience fewer breakdowns and unplanned stoppages.

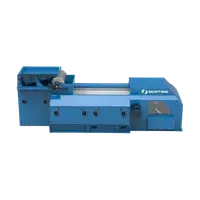

Magnet Type

Electromagnet

Installation Position

Suspended above conveyor belts

Inline or crossbelt configurations available

Belt Construction

Heavy-duty continuous belt

Armored belt option for sharp, abrasive, or high-impact tramp metal

Overband Construction

Frame: Heavy-duty fabricated steel

Designed for high-impact, dusty, and abrasive environments

Discharge Method

Automatic tramp metal discharge via continuously running belt

Discharge direction configured to suit installation

Operating Mode

Continuous operation

Suitable for high-throughput processing lines

Power Requirements

Electromagnetic system requiring external power supply

Electrical specifications vary by magnet size and application

Control Options

Supplied with control equipment for magnet operation

Integration available with plant control systems

Finish

Painted steel finish

Finish options available to suit operating environment

Optional Features

- Armored belt for severe-duty applications

- Inline or crossbelt mounting arrangements

- Custom magnet sizing to match conveyor width and burden depth

FAQ's

An ElectroMax Overband Magnet is a suspended electromagnetic separator that removes ferrous tramp metal from materials conveyed on belt systems using automatic metal discharge.

ElectroMax Overband Magnets remove ferrous metals such as iron, steel, bolts, bars, tools, and other magnetic contaminants.

They are installed above conveyor belts, either inline or crossbelt, to remove tramp metal before it reaches downstream equipment.

The magnet is automatically cleared of captured metal by the belt, which carries the metal to a discharge point. The belt itself does not clean itself.

Yes. They are designed for high-impact, high-volume environments including recycling plants, quarries, and mining operations.

By removing tramp metal before it reaches critical equipment, ElectroMax Overband Magnets help prevent damage, breakdowns, and unplanned shutdowns.

Application Photos

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.