About Us

Who We Are

Bunting is a global leader in the design, manufacturing, and distribution of advanced magnetic separation, metal detection, and conveying solutions. For over 60 years, we've partnered with industries worldwide, delivering custom-engineered equipment tailored precisely to each customer's unique challenges and facility requirements.

With two strategically located global headquarters—Newton, Kansas for North America, and Redditch, England for Europe—Bunting ensures consistent, expert support across continents. Our international presence is further bolstered by offices, distributors, and agents spanning the globe, guaranteeing prompt and professional service wherever your operations may be.

From cutting-edge magnetic separators and precision metal detectors to robust conveying systems, Bunting equipment is built to protect your products, enhance production efficiency, and safeguard your brand. We proudly serve diverse industries, including food processing, pharmaceuticals, plastics, recycling, auto shredding, mining, ceramics, textiles, metal stamping, and many more.

Driven by a legacy of innovation since 1959, our family-owned business is committed to continuous advancement, integrating new technologies into our solutions to meet the evolving demands of modern industry. Choose Bunting for global reach, local support, and unmatched expertise in magnetic solutions.

We exist to help manufacturers across the globe:

- Protect equipment from damage = Less downtime

- Ensure product purity = Protect your reputation

- Improve processing efficiency = Increase your profits

We’re driven by innovation, built on integrity, and backed by decades of experience.

What We Do

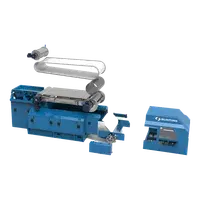

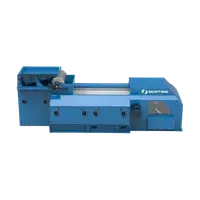

Our magnetic separators are engineered to efficiently remove ferrous and magnetic materials from non-magnetic products, ensuring purity in industries like mining, recycling, and food processing.

We provide advanced metal detection systems designed to identify and eliminate metal contamination across various sectors, including quarrying, mining, food, recycling, and plastics.

Our material handling conveyors are designed to work seamlessly with our magnetic separation and metal detection equipment, optimizing the transport and purification of materials.

Industries We Serve

Protect your belts and crushers from tramp metal while withstanding the harshest environment.

Identify and remove ferrous and paramagnetic particles from battery materials and slurries.

Efficiently detect and remove ferrous, non-ferrous, and stainless steel contaminants.

Remove and detect metal contaminants throughout your food & pharma processing operations.

Permanent magnetic conveyors and conveyor components for the metal stamping industry.

Bunting supplies complete systems for material recovery and recycling needs.

Remove tramp metal, recover valuable minerals, and protect processing equipment.

Bunting is the leader for Metal Detection in Plastics. Protect your equipment from costly repairs.

Remove metals from powder and chemical applications to prevent costly damage to processing equipment.

Bunting empowers the printing and decorating sector with innovative solutions designed for flawless results

Your Trusted Global Partner in Magnetic Separation, Metal Detection, and Conveying Solutions

Since 1959, Bunting Magnetics has been a trusted, family-owned leader in the magnetic separation and metal detection industry. With over six decades of proven performance, we provide not only innovative products but a long-term partnership grounded in stability, reliability, and a commitment to your success.

Industry-Leading Engineering and Customization

At Bunting, we deliver precision-engineered solutions tailored to your exact specifications. Our team of experts uses advanced computer-aided design (CAD), finite element analysis, and industry-specific simulations to create equipment that performs efficiently in even the most demanding applications. Whether you need magnetic separators, metal detectors, or integrated conveyor systems, we build solutions that solve your real-world challenges.

Built for Performance. Backed by Quality.

Every product we manufacture is built to last. Our ISO-certified facilities follow rigorous quality control processes to ensure durability, consistency, and superior performance. Bunting equipment is trusted worldwide for its low maintenance, high efficiency, and reliable results.

Global Service. Local Support.

With headquarters in Newton, Kansas and Redditch, England—and a vast network of international distributors and agents—we provide comprehensive customer support around the world. Whether you need parts, service, or expert application advice, Bunting is your global partner in magnetic technology.

Optimize Your Process. Protect Your Brand.

From safeguarding food quality to protecting processing equipment and improving end-product purity, our solutions help customers maximize productivity while minimizing downtime. Trust Bunting to deliver magnetic separation and detection systems that elevate operational performance and reinforce your reputation for quality.

Animation

Accreditations and Memberships

Bunting is proud to be a member of numerous professional organizations and trade bodies across a range of industries, and we are accredited by several complementary associations in support of our commitment to the highest standards.

Our employees also demonstrate their experience, skills, and expertise through individual professional memberships, ensuring that we consistently deliver trusted solutions and industry-leading service.

Below is more information about the organizations and associations Bunting and our staff are affiliated with.

ISO 9001:2015

Sets criteria for quality management systems focusing on customer satisfaction, leadership, process approach, and continual improvement to ensure consistent, reliable delivery of high-quality products and services that meet customer and regulatory requirements.

ISO 14001:2015

Specifies requirements for environmental management systems that help organizations systematically improve environmental performance, reduce impact, and support sustainability goals through responsible resource use and compliance with environmental regulations.

ISO 45001:2018

Defines occupational health and safety management system requirements to prevent workplace injuries and illnesses, promote proactive safety improvements, and ensure a safe, healthy working environment for employees across all industries.

EcoVadis

Global platform assessing corporate sustainability in environment, labor, ethics, and procurement, helping organizations manage ESG risks, ensure regulatory compliance, and improve transparency and performance across their supply chains.

EHEDG

Promotes food safety by advancing hygienic engineering and design, providing guidance to manufacturers to meet food safety regulations and hygienic machinery standards for safe handling, processing, and packaging of food products.

BVSE

Largest German and European association representing 950 recycling and waste companies focused on conserving natural resources, saving energy, and advancing climate protection through responsible secondary raw material supply and waste management.

PEMA

Unites companies supplying process equipment and systems, fostering industry connections, technical knowledge, and professional growth across sectors including mining, chemicals, food, and more through networking and collaboration opportunities.

PMMI

Supports over 950 packaging and processing manufacturers and suppliers, driving innovation, industry advocacy, and business growth through resources, training, and global events for the packaging and processing technology sectors.

AGG1

The aggregates industry’s premier event, featuring exhibits and education on the latest technologies, equipment, and innovations for aggregates producers and suppliers, supporting professional development and industry advancement.

British Metals Recycling Association

Represents over 250 UK metal recycling organizations producing environmentally responsible raw materials for global metal manufacturers, supporting sustainable recycling practices and contributing to resource conservation and circular economy initiatives.

British Safety Council

Since 1957, promotes workplace health and safety worldwide by helping members prevent accidents, reduce hazards, and improve worker well-being through advocacy, education, and the development of effective safety standards.

Plastic Industry Association

Represents the entire plastics supply chain, advancing sustainability, innovation, and competitiveness while advocating for responsible plastics use and promoting industry growth, education, and collaboration across the plastics sector.

Contact Us

Not all applications are same. Contact us to discuss your application parameters and we will match you up with right solutions.