Pneumatic Metal Detectors / Separators

![]()

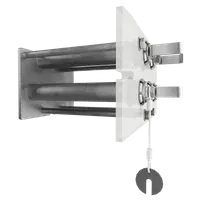

Bunting’s pneumatic metal detectors and separators are designed to detect and remove metal contaminants from materials conveyed through vacuum or pressure pneumatic lines. Engineered for precision in both food-grade and industrial environments, these systems ensure product purity and protect downstream equipment in applications ranging from flour and spices to plastic pellets and regrind.

Featuring high-sensitivity detection, advanced self-monitoring, and fast-acting reject systems, Bunting’s pneumatic units integrate easily into new or existing pipelines. Optional configurations are available for hygienic washdown, ATEX-rated environments, and Clean-in-Place (CIP) systems, delivering reliable performance in even the most demanding production settings.

By catching metal contamination early—before it damages equipment, compromises quality, or reaches customers—Bunting pneumatic detectors help manufacturers reduce downtime, avoid costly recalls, and maintain compliance with strict safety and quality standards. The result is greater operational efficiency, improved product integrity, and long-term protection of both brand and equipment.

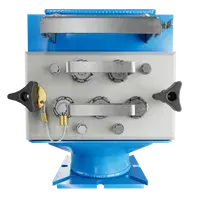

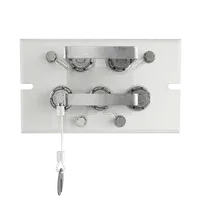

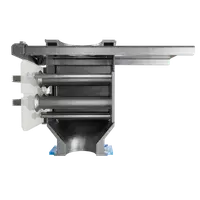

Pneumatic Metal Detector / Separator

Applications

Powdered and granular food products transported through pneumatic conveying systems

Materials Handled

Flour, starch, sugar, spices, cocoa powder, milk powder, grains, and other dry bulk ingredients

Benefits

- Delivers the highest detection sensitivity for pneumatic conveying systems

- Advanced diagnostics and self-monitoring for reliable performance and system visibility

- Automatically compensates for product effect to reduce false rejects and improve accuracy

- Ideal for high-throughput food lines requiring hygienic, enclosed metal detection

- Minimizes contamination risk and supports compliance with food safety standards (FDA, USDA, GFSI)

- Engineered for integration into vertical or horizontal pressure and vacuum pipelines

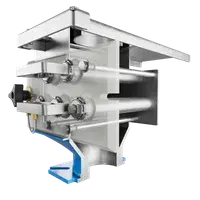

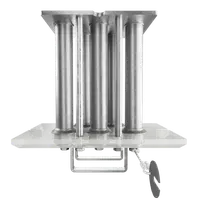

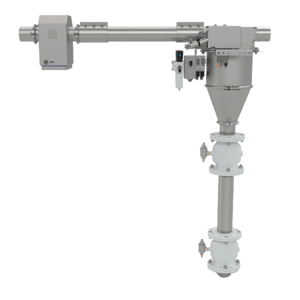

Pneumatic Metal Detector / Separator

Applications

Plastics processing, compounding, and recycling lines using vacuum or pressure conveying systems

Materials Handled

Plastic pellets, regrind, powders, and shredded plastic conveyed in closed pneumatic systems

Benefits

- Detects ferrous, nonferrous, and stainless-steel contaminants in high-speed pneumatic lines

- Fast-acting reject mechanism with flap or double pinch-valve for minimal product loss

- Designed for continuous operation under vacuum or pressure

- Maintains line integrity with positive speed control and precision timing

- Optional ATEX configuration available for use in explosive or dust-sensitive environments

- Supports equipment protection and material purity in closed-loop conveying processes

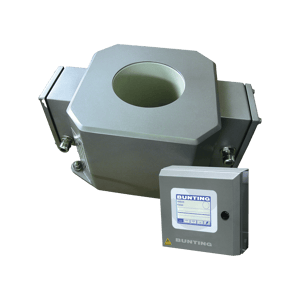

Other Pneumatic Metal Detectors

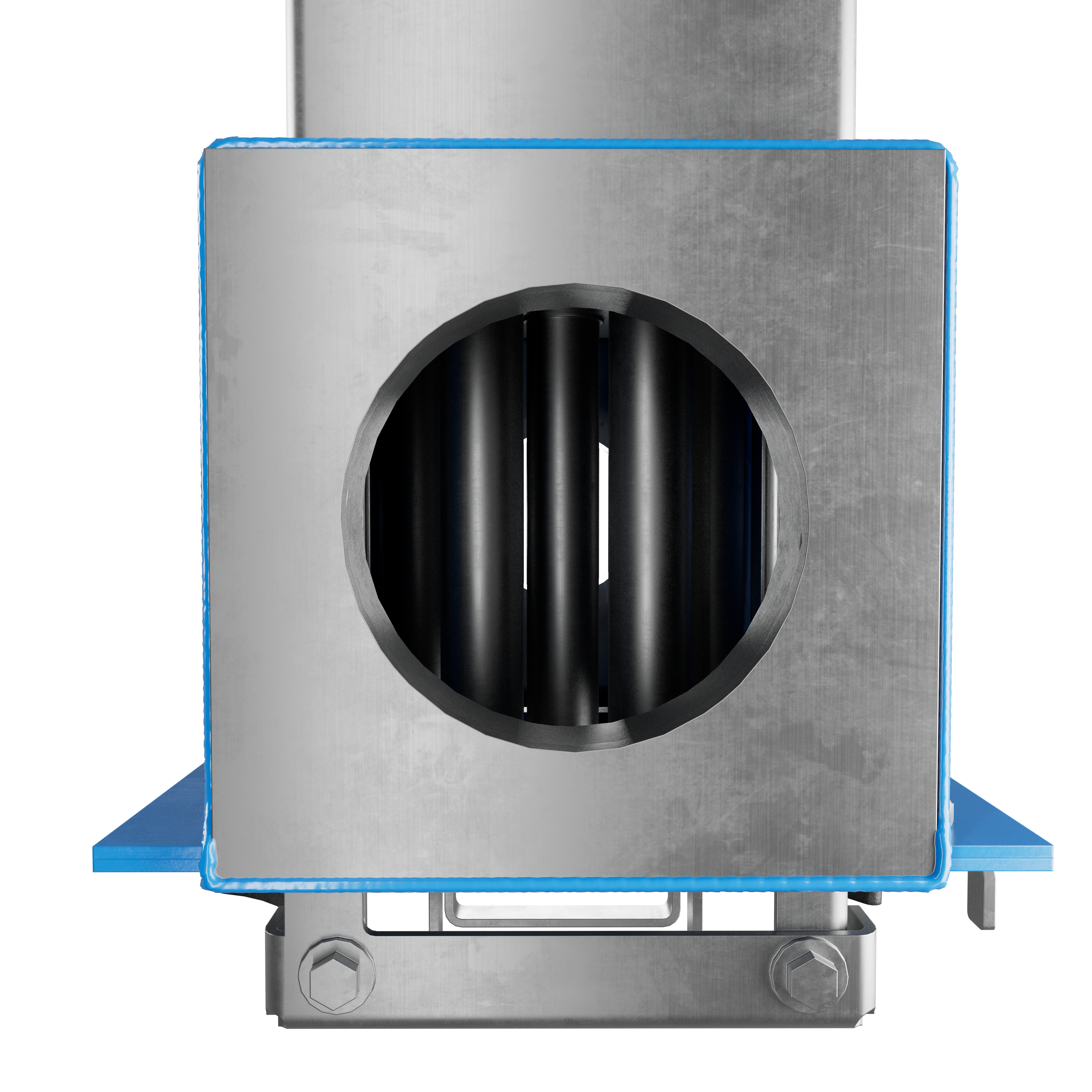

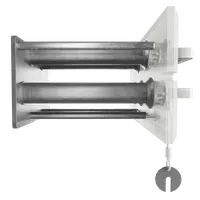

Performer P

A high-sensitivity metal detector for gravity and pneumatic conveying lines. Featuring patented coil technology and advanced controls, it ensures reliable detection in compact spaces and can be installed vertically or horizontally for maximum flexibility.

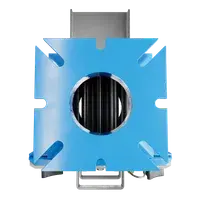

Performer R

A cost-effective, collar-style metal detector for gravity and pneumatic conveying lines, ideal for bulk materials, liquids, pastes, and slurries. Featuring high-frequency, triple-coil precision and advanced digital controls, it offers easy installation, reliable detection, and durable performance—even in demanding environments.

About

Bunting's Performer Series Pipeline Metal Detectors provide dependable contamination detection for liquids, pastes, and slurries. Designed for demanding applications in food, pharmaceutical, and industrial settings, these systems help maintain product quality and protect equipment.

These tunnel metal detectors feature customizable designs that can seamlessly integrate into existing production lines. They come equipped with user-friendly control panels for easy operation and advanced detection capabilities that deliver superior sensitivity. Additionally, the waterproof, epoxy-filled search heads enhance durability, while efficient rejection systems minimize product loss.

Our pipeline metal detectors feature:

- Advanced detection technology for enhanced sensitivity

- Customizable designs for diverse pipeline setups and pressure needs

- Hygienic builds that meet stringent food safety standards

- Durable construction for reliable performance in tough environments

- Simple interfaces for easy use and upkeep

From the cost-effective Performer V Eco to the high-pressure Performer P Pro, Bunting offers a complete line of pipeline metal detection solutions. Our systems integrate smoothly into existing production, reducing downtime while improving product safety and quality.

Protect your brand, ensure consumer safety, and improve your production with Bunting's reliable Pipeline Metal Detectors. Contact us today to learn how our custom solutions can enhance your contamination control efforts.

Why Choose Bunting's Performer Metal Detectors?

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.