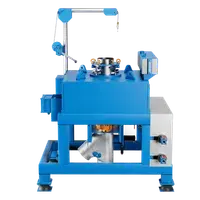

Performer Pro UB

Under Belt Metal Detector

The Performer Pro UB is a single-plate metal detector designed for under-conveyor and vibrating chute installations. Suitable for bulk material heights up to 9.8 inches (250 mm), it offers versatile metal detection across multiple industrial applications with seamless integration into conveyor systems.

Options / Features

Compact metal detector specifically engineered for installation under conveyor belts or vibratory chutes

Ideal for detecting metal contaminants in material heights up to 9.8 inches (250 mm)

Can be easily installed in conveyor belts and vibrating chutes with a dedicated metal-free zone

Animation

- About

- Benefits

- Tech Specs

Metal contamination is a critical challenge across industrial processing environments, threatening product quality, consumer safety, and operational efficiency. The Performer Pro UB is a solution designed to address these complex detection requirements with precision and reliability.

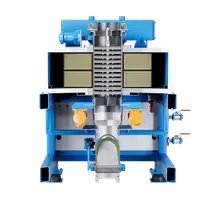

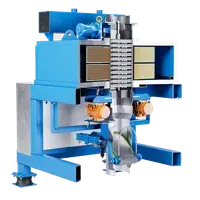

Engineered for versatility, the Performer Pro UB offers advanced metal detection capabilities for industries ranging from food processing to pharmaceutical manufacturing. Its single-plate design enables seamless integration under conveyor belts and vibratory channels, providing a flexible approach to contaminant identification that adapts to material handling systems.

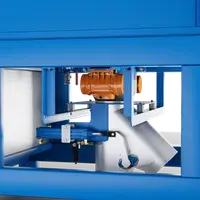

The detector's technology focuses on detecting ferrous, non-ferrous, and stainless steel contaminants within bulk materials up to 9.8 inches (250 mm) in height. This capability ensures comprehensive screening that protects both product integrity and expensive processing equipment from potential metal-related damage.

The Performer Pro UB represents a commitment to quality assurance and operational excellence. By proactively identifying potential contamination risks, it supports manufacturers in maintaining stringent safety standards and reducing financial losses associated with product recalls or equipment failures.

Developed with input from industry professionals and backed by rigorous engineering principles, the Performer Pro UB stands as a testament to innovative metal detection technology. It provides businesses with a reliable, efficient, and adaptable solution for maintaining the highest levels of product quality and safety across multiple industrial sectors.

Enhanced Product Safety: The Performer Pro UB effectively detects metal contaminants in bulk materials, helping to prevent product recalls and ensuring consumer safety. By identifying ferrous, non-ferrous, and stainless steel contaminants, it safeguards both product integrity and brand reputation.

Operational Efficiency: Designed for seamless integration under conveyor belts and vibratory channels, the Performer Pro UB minimizes installation time and disruption. Its compact design allows for efficient use of space while maintaining high detection performance, contributing to smoother production processes.

Reduced Downtime: With its robust construction and reliable performance, the Performer Pro UB minimizes the risk of equipment failure due to metal contamination. This reliability translates to reduced downtime and maintenance costs, enhancing overall operational productivity.

Versatile Applications: The Performer Pro UB metal detector is suitable for a wide range of industries, including food processing, pharmaceuticals, and manufacturing. Its adaptability to various material heights and types makes it an essential tool for maintaining quality control across diverse applications.

Cost-Effective Quality Assurance: By proactively identifying metal contaminants, the Performer Pro UB helps reduce waste and minimize financial losses associated with product recalls or equipment damage. This cost-effective approach supports long-term profitability and sustainability in manufacturing operations.

Detection Capability

Detects ferrous, non-ferrous, and stainless steel contaminants

Effective for bulk material heights up to 9.8 inches (250 mm)

Installation

Single-plate design for under-belt or vibratory channel mounting

Requires metal-free zone for optimal performance

Sensitivity

High-precision detection across various product types

Adjustable sensitivity settings to suit specific application needs

Control Interface

User-friendly control panel with intuitive operation

Multiple operating modes for different product characteristics

Construction

Robust, industrial-grade materials for durability

IP65 rated for dust and water resistance (optional IP69K available)

Power Requirements

110-240 VAC, 50/60 Hz (specific requirements available on request)

Low power consumption for energy efficiency

Operating Temperature

Standard range: 14°F to 122°F (-10°C to 50°C)

Extended range available for extreme environments

Connectivity

Standard outputs for reject systems and alarms

Optional data logging and reporting capabilities

Compliance

Meets FDA and HACCP requirements for food safety

CE certified for electromagnetic compatibility (EMC)

Dimensions

Customizable to fit specific conveyor widths

Compact design for space-efficient installation

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.