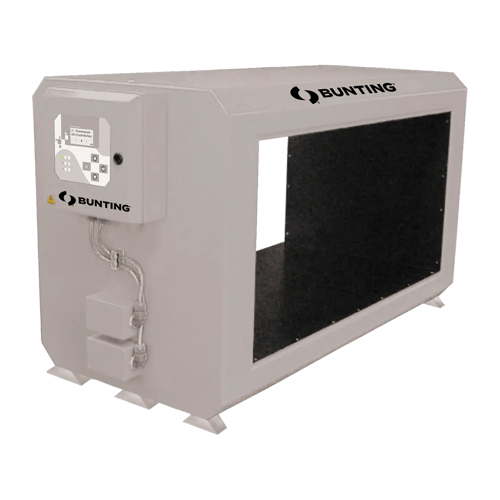

Performer Pro OT

Tunnel Metal Detector

The Performer Pro OT is an adaptable tunnel metal detector with integrated or remote evaluation electronics, suitable for horizontal or vertical installation. Flexible for conveyor belts, free fall, and product slides, it offers tunnel sizes from 2" (5 cm) to over 80" (20 m).

Options / Features

The Performer Pro OT uses digital signal processing, allowing for precise metal identification.

Proven performance in rough environments with maintenance-free, long-term operation and versions suitable for outdoor and high-temperature applications.

Includes CAN-BUS data port allowing network connection of up to 125 metal detectors, with options for remote diagnosis, parameter changes, and software updates.

Animation

- About

- Benefits

- Tech Specs

In today’s manufacturing landscape, maintaining high standards of quality control is essential for success. The Performer Pro OT metal detector offers a reliable solution for contamination screening, specifically designed for industries such as food processing, pharmaceuticals, and packaging. This advanced detector helps ensure that products are free from metal contaminants, safeguarding both consumer safety and brand integrity.

The Performer Pro OT is built for flexibility, adapting seamlessly to various production environments. It can be installed on conveyor belts, free-fall systems, or product slides, making it suitable for a wide range of applications. With tunnel sizes that range from 2 inches (5 centimetres) to 80 inches (20 metres), it accommodates different materials and product dimensions, allowing manufacturers to customize their setup according to specific needs. This versatility makes the Performer Pro OT an ideal choice for operations that handle diverse product lines.

One of the standout features of the Performer Pro OT is its choice between integrated or remote electronics. This design simplifies installation and improves operational efficiency. The user-friendly control panel provides straightforward access to essential functions, enabling quick adjustments and monitoring. Additionally, multi-tiered security measures ensure that only authorized personnel can make critical changes, adding an extra layer of protection to your quality assurance processes.

Engineered to perform in demanding industrial environments, the Performer Pro OT consistently identifies metal contaminants even under challenging conditions. Its robust construction and advanced detection technology help manufacturers comply with stringent industry standards such as HACCP, IFS Food, and BRC Food. By ensuring that products meet these regulations, the Performer Pro OT plays a vital role in maintaining trust with consumers and regulatory bodies.

Enhanced Product Safety: Ensures superior contamination screening across various industries, protecting consumers and maintaining product integrity.

Operational Flexibility: Suitable for horizontal or vertical installation, adaptable to conveyor belts, free fall, and product slides for diverse manufacturing needs.

Customizable Detection: Offers tunnel sizes from 2 in (5 cm) to over 80 in (20 m), accommodating a wide range of product dimensions and production volumes.

Streamlined Integration: Available with integrated or remote evaluation electronics, simplifying installation and reducing spatial requirements in production areas.

Regulatory Compliance: Helps manufacturers meet stringent industry standards like HACCP, IFS Food, and BRC Food, ensuring adherence to safety regulations.

Cost-Effective Quality Control: Prevents costly product recalls and protects valuable production equipment from damage, resulting in long-term cost savings.

User-Friendly Operation: Features an intuitive control panel, enabling easy operation and secure process monitoring for efficient quality management.

Detection Capability

Detects ferrous, non-ferrous, and stainless steel contaminants

Sensitivity varies based on aperture size, product, and environmental conditions

Tunnel Sizes

Range from 2 in (5 cm) to over 80 in (20 m)

Custom sizes available to suit specific application needs

Installation Options

Horizontal or vertical orientation

Suitable for conveyor belts, free fall, and product slides

Control Unit

Integrated or remote evaluation electronics

Multi-level password protection

Construction

Robust design for industrial environments

IP65 protection standard (higher ratings available)

Power Supply

100-240 VAC, 50/60 Hz (standard)

Optional 24 VDC version available

Operating Temperature

Standard: 14°F to 122°F (-10°C to 50°C)

High-temperature version available

Connectivity

Various I/O options for system integration

Optional network capabilities for multi-unit setups

Compliance

Meets CE and applicable FDA requirements

Supports HACCP, IFS, and BRC standards

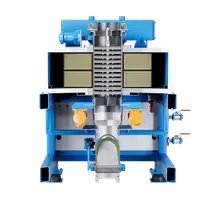

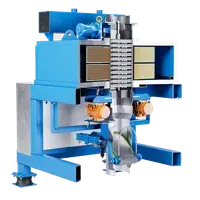

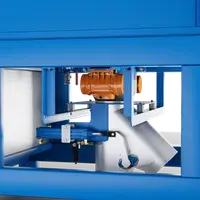

Application Photos

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.