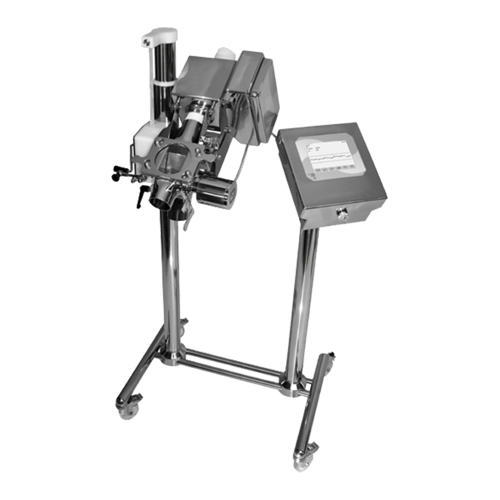

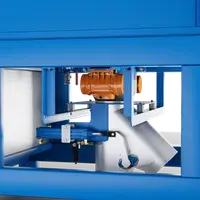

Performer Pharma Elite

Tablet Metal Detector

The Performer Pharma Elite is a state-of-the-art metal separator designed for installation on tablet presses or dust collectors within the pharmaceutical industry. This system is specifically engineered for the inspection of capsules, tablets, and sugar-coated tablets, ensuring the highest levels of product safety and quality. Its hygienic design and ease of cleaning prevent cross-contamination between product batches, safeguarding against potential risks and maintaining the integrity of your production process.

Options / Features

Utilizes advanced metal detection technology to identify and remove all types of metallic foreign bodies, protecting your production, reputation, and customers.

Features a hygienic structure and easy cleanability to prevent cross-contamination, with options for dustproof or wash-in-place configurations.

Purpose-built for capsules, tablets, and sugar-coated pills, ensuring optimal detection sensitivity and minimal false rejects in pharmaceutical applications.

Animation

- About

- Benefits

- Tech Specs

The Performer Pharma Elite is Bunting's advanced metal separator, meticulously designed for installation on tablet presses or dust collectors within the pharmaceutical industry. This state-of-the-art system is specifically engineered for the inspection of capsules, tablets, and sugar-coated tablets, guaranteeing the highest levels of product safety and quality.

A key feature is its hygienic design and ease of cleaning, which effectively prevent cross-contamination between product batches. This safeguarding is crucial for preventing potential risks and maintaining the integrity of your production process.

The Performer Pharma Elite relies on advanced metal detection technology to reliably identify and remove all types of metallic foreign bodies. This ensures protection for your production, strengthens your reputation, and most importantly, safeguards your customers.

The system's design emphasizes hygiene and easy cleanability to further prevent cross-contamination, with available options for dustproof or wash-in-place configurations. In addition, the quick-reaction separation diverter minimizes material loss while accelerating cleaning work, optimizing operational efficiency.

Compliance is paramount, and the Performer Pharma Elite meets relevant hygiene guidelines. It includes standard software features such as password-protected user management, automatic test requests, and comprehensive reporting options. Furthermore, tailored solutions are available to facilitate seamless integration, reduce costs, and lower introduction barriers, particularly when working with existing product lines.

For connectivity, the Performer Pharma Elite offers options for analogue signals, bus systems, or Ethernet connectivity to PLCs, process control systems, or other machinery. Digital networking via OPC UA protocol ensures the smooth transmission of operating conditions and production-critical values.

Bunting backs the Performer Pharma Elite with a dedicated team of professionals, from sales and application specialists to mechanical and electronic development experts, all the way through production and after-sales support. We provide support with modern equipment and a process environment embedded in ISO 9001 standards.

Contact us today to discover how the Performer Pharma Elite can significantly improve the safety, compliance, and overall efficiency of your pharmaceutical production line.

Enhanced Product Safety: Ensures the highest level of safety by detecting and removing even the smallest metallic contaminants from capsules, tablets, and coated pills. This protects patients and safeguards your brand reputation.

Reduced Risk of Contamination: The hygienic design and easy-to-clean components minimize the risk of cross-contamination between product batches, complying with stringent pharmaceutical regulations.

Improved Production Efficiency: The fast-acting separation system minimizes product loss during contaminant removal, while the streamlined design enables quick cleaning and maintenance, maximizing uptime.

Compliance with Industry Standards: Helps your facility comply with GMP (Good Manufacturing Practice), FDA regulations, and other relevant industry standards, avoiding potential penalties and ensuring product quality.

Protection of Downstream Equipment: Prevents metallic contaminants from damaging sensitive and expensive downstream processing equipment, reducing maintenance costs and extending the lifespan of your machinery.

Data Tracking and Reporting: Standard software features provide detailed reports and audit trails, supporting traceability and quality control efforts.

Reduced False Rejects: Optimized for the unique characteristics of pharmaceutical products, minimizing false rejects and reducing waste while maintaining high levels of detection sensitivity.

Seamless Integration: Designed for easy integration into existing tablet press and dust collection systems, minimizing disruption to your production line.

Peace of Mind: Provides the confidence that your pharmaceutical products meet the highest standards of quality and safety, protecting your patients and your brand.

Detection Sensitivity

Ferrous: down to 0.1 mm

Non-ferrous: down to 0.2 mm

Stainless steel (316): down to 0.3 mm (Actual sensitivity depends on product properties and environmental conditions)

Throughput Rate

Up to 30,000 tablets/min (depending on product size and aperture dimensions)

Operating Frequency

Multi-frequency technology

Power Supply

100-240 VAC, 50/60 Hz

Power Consumption

50 VA (typical)

Operating Temperature

32°F to 104°F (0°C to +40°C)

Relative Humidity

20% to 90% non-condensing

Protection Class

IP65 (IP69K optional)

Material

Stainless steel 1.4301 (AISI 304)

User Interface

7" color touchscreen

Multi-language support

Data Interfaces

USB, Ethernet, OPC UA

Optional: PROFIBUS, PROFINET, DeviceNet

Compliance

CE, FDA CFR 21 Part 11

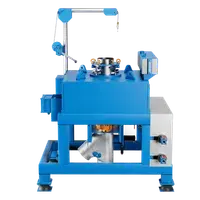

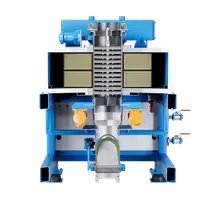

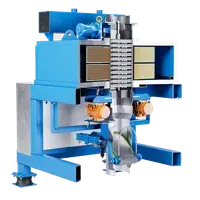

Application Photos

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.