Performer Elite IT

Tunnel Metal Detector

Bunting's tunnel-style metal detectors provide reliability and precision for detecting and removing metal contaminants in bulk and packaged products. Designed for industries like food processing, plastics, and recycling, these detectors help protect your equipment, maintain product quality, and ensure regulatory compliance.

Options / Features

Capable of detecting metal particles as small as 1.5mm for ferrous and non-ferrous metals, ensuring product purity and compliance with industry standards.

Equipped with the advanced AMD 07 control unit featuring a user-friendly touch screen interface, dynamic auto-tracking, and automatic sensitivity calibration for optimal performance.

Utilizes advanced technology to significantly reduce the necessary metal-free area for installation, making it ideal for tight spaces in production lines.

Animation

- About

- Benefits

- Tech Specs

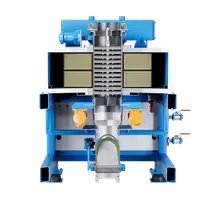

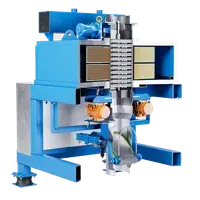

Industrial manufacturing demands precision, and the Performer IT Elite metal detector rises to this challenge with advanced contamination screening technology. Engineered to meet the most rigorous quality control standards, this sophisticated device represents a breakthrough in metal detection methodology.

At its core, the Performer IT Elite utilizes multi-frequency electromagnetic detection technology that adapts seamlessly to varying material densities. This intelligent approach minimizes false detections while maintaining exceptional sensitivity to metal contaminants across diverse production environments. Whether in food processing, pharmaceutical manufacturing, or chemical production, the detector provides consistent, reliable performance.

The detector's robust design is built to withstand demanding industrial conditions, integrating cutting-edge hardware with adaptive signal processing algorithms. By identifying minute metal particles across different product types, the Performer IT Elite becomes an essential component in quality assurance protocols. Manufacturers can rely on its ability to help maintain product integrity and ensure consumer safety, meeting and often exceeding stringent industry regulations.

Beyond its technical capabilities, the Performer IT Elite represents a commitment to precision engineering. It transforms metal detection from a simple screening process into a sophisticated quality control solution, giving manufacturers confidence in their production standards and product safety.

Superior Detection Accuracy: Detects metal particles as small as 0.06" (1.5mm) for ferrous and non-ferrous metals

Space-Efficient Design:

- Minimal floor space is required.

- Reduced metal-free area for easier integration into production lines

Versatile Applications:

- Ideal for food processing, chemicals, pharmaceuticals, and other clean environments

- Suitable for quality inspection and machine protection in conveyor systems

User-Friendly Operation:

- Equipped with Elite control unit featuring a touch screen interface

- Intuitive operation with product storage memory for up to 500 products

High-Speed Performance: Capable of detecting metals in materials transported at speeds up to 98 ft/s (30 m/s)

Quality Assurance Compliance: Meets requirements for HACCP, IFS, BRC, and SQF quality systems

Advanced Features:

- Network connectivity and data management capabilities

- Dynamic auto-tracking for maximum sensitivity during operation

- Multi-filter system using digital filtration for stability in harsh environments

Detection Capability

Ferrous, non-ferrous, and stainless steel contaminants

Aperture Sizes

Width: 4"-80" (100mm to 2000mm)

Height: 8"-24" (200mm to 600mm)

Operating Frequency

Multi-frequency operation

Automatic frequency selection for optimal performance

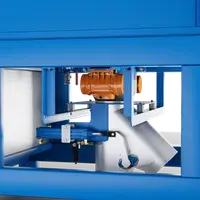

Control Unit

Elite with 7" color touchscreen display

IP65 protection rating (optional IP69K)

Product Memory

Storage for up to 500 product settings

Connectivity

Ethernet, USB, and RS232/485 interfaces

Optional Wi-Fi connectivity

Power Supply

100-240 VAC, 50/60 Hz

Operating Temperature

Standard: 32°F to 104°F (0°C to +40°C)

Optional: -22°F to 131°F (-30°C to +55°C)

Construction

Stainless steel housing

FDA-approved materials for food contact areas

Compliance

CE, UL, CSA certified

Meets IFS, BRC, FSSC 22000 standards

Additional Features

Auto-balance and auto-calibration functions

Multi-language support

Password-protected access levels

Application Photos

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.