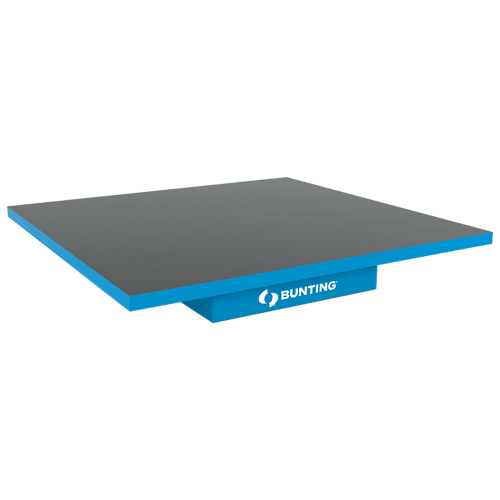

Performer Eco UBL

Under Belt Metal Detector

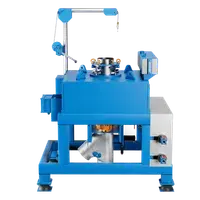

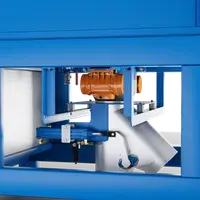

The Performer ECO UBL is a low profile single-surface metal detector designed for installation in belt conveyors, vibratory chutes, and material slides. It is specifically engineered to detect metals as inclusions or loose parts in industrial processing environments, offering high sensitivity and reliable performance for medium bulk material heights.

Options / Features

Compact metal detector specifically engineered for installation under conveyor belts, vibratory chutes and material slides

Capable of identifying ferrous, non-ferrous, and stainless steel contaminants with precision

Single-surface configuration enables efficient installation with minimal production disruption

Animation

- About

- Benefits

- Tech Specs

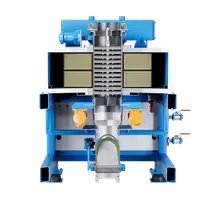

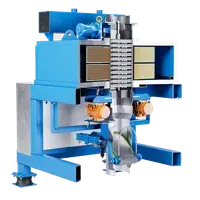

The Performer ECO UBL is a single-surface metal detector engineered for comprehensive industrial applications. Designed to detect ferrous, non-ferrous, and stainless steel contaminants, this metal detection system provides reliable screening across multiple manufacturing environments including plastics processing, recycling operations, textile manufacturing, and general industrial production.

With the capability to handle bulk material heights ranging from 1.2 to 9.8 inches (30 mm to 250 mm), the Performer ECO UBL utilizes digital signal processing to ensure consistent and precise metal detection. Its user-friendly control interface allows operators to easily monitor and manage detection processes, while its versatile design enables seamless integration into belt conveyors, vibratory chutes, and material slides.

The benefits of the Performer ECO UBL include enhanced product quality, equipment protection, and operational efficiency. By identifying potential metal contaminants, manufacturers can prevent costly equipment damage, reduce waste, and maintain rigorous quality assurance standards. The detector's advanced technology supports compliance requirements while providing a cost-effective solution for metal detection across diverse industrial sectors.

Manufacturers seeking a reliable, adaptable metal detection system will find the Performer ECO UBL to be a robust solution that addresses critical quality control challenges. Its high-sensitivity detection capabilities and flexible application make it an essential tool for maintaining product integrity and operational excellence.

Enhanced Product Quality: The Performer ECO UBL provides comprehensive metal contamination detection, ensuring product purity and preventing potential quality issues. By identifying even minute metal fragments, it helps maintain the highest standards of product integrity across various industrial processes.

Operational Efficiency: Designed for seamless integration, this metal detector minimizes production interruptions and streamlines quality control processes. Its advanced detection capabilities allow continuous monitoring without compromising production speed or workflow.

Cost-Effective Protection: By proactively detecting metal contaminants, the Performer ECO UBL helps prevent expensive equipment damage, reduces waste, and minimizes the risk of product recalls. This approach translates to significant long-term cost savings and improved operational reliability.

Versatile Performance: Suitable for multiple industries, the Performer ECO UBL adapts to diverse material types and processing environments. Its flexible design ensures consistent performance across plastics, recycling, textile, and manufacturing applications.

Compliance and Safety: The detector supports rigorous quality assurance standards, helping manufacturers meet regulatory requirements and maintain consumer safety. Its precise detection capabilities provide an additional layer of protection for both products and production processes.

Detection Capability

Detects ferrous, non-ferrous, and stainless steel contaminants

Suitable for medium bulk material heights

Installation

Single-plate design for belt conveyors, vibratory chutes, and material slides

Control Interface

User-friendly control panel with intuitive operation

Construction

Robust, industrial-grade materials for durability

Power Requirements

100-200 VAC, 50/60 Hz (specific requirements available on request)

Operating Temperature

Standard range: 14°F to 122°F (-10°C to 50°C)

Extended range available for extreme environments

Connectivity

Standard outputs for reject systems and alarms

Compliance

Meets industry standards for metal detection in industrial processing environments

Dimensions

Customizable to fit specific conveyor widths

Compact design for space-efficient installation

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.