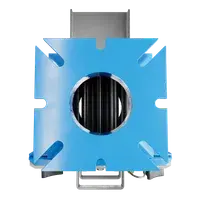

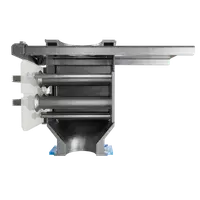

Inline Metal Detectors

![]()

| Materials: | Liquids, slurries, sauces, pastes, ground meat, and pumped food products |

| Detects: | Ferrous and non-ferrous |

| Applications |

Food processing, meat and poultry, dairy, sauces, baby food, pet food, and other pumped or pipeline product streams |

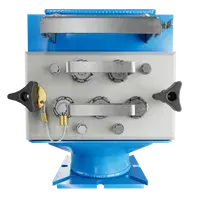

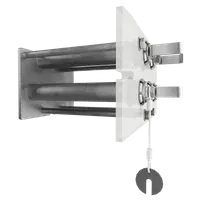

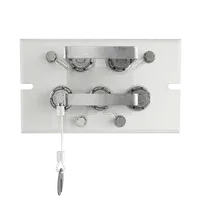

Inline Metal Detector / Separator

Applications

Food processing, beverage production, dairy, sauces, soups, and viscous product handling

Materials Handled

Liquids, pastes, slurries, and semi-viscous products conveyed under pressure

Benefits

- Detects and removes ferrous and nonferrous metals from pumped product streams

- Custom-designed to fit any pipeline application requirements

- Features advanced 05 or 07 controls for superior detection sensitivity

- 3-way separation mechanism compatible with Clean-in-Place (CIP) systems

- Stainless steel construction ensures durability and compliance with sanitary standards

- Enhances product purity and protects downstream equipment from metal contamination

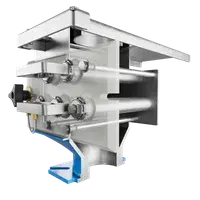

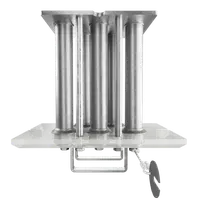

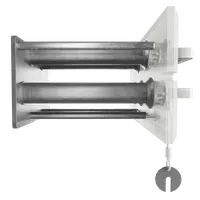

Inline Metal Detector / Separator

Applications

Ground meat processing, sausage production, and meat patty forming lines

Materials Handled

Ground meats, meat pastes, and other viscous meat products conveyed under vacuum or pressure

Benefits

- Detects and separates ferrous and nonferrous metals, including encapsulated contaminants

- Integrates seamlessly with commercial vacuum fillers and meat processing equipment

- Fast-acting pneumatic reject mechanism minimizes product loss and maintains product integrity

- Tool-free disassembly for easy cleaning and maintenance

- All components made of stainless steel or food-safe plastic, ensuring hygiene and compliance

- Touchscreen interface with self-explanatory menu structure for easy operation

- Pressure washer safe design with components secured to prevent loss during cleaning

About

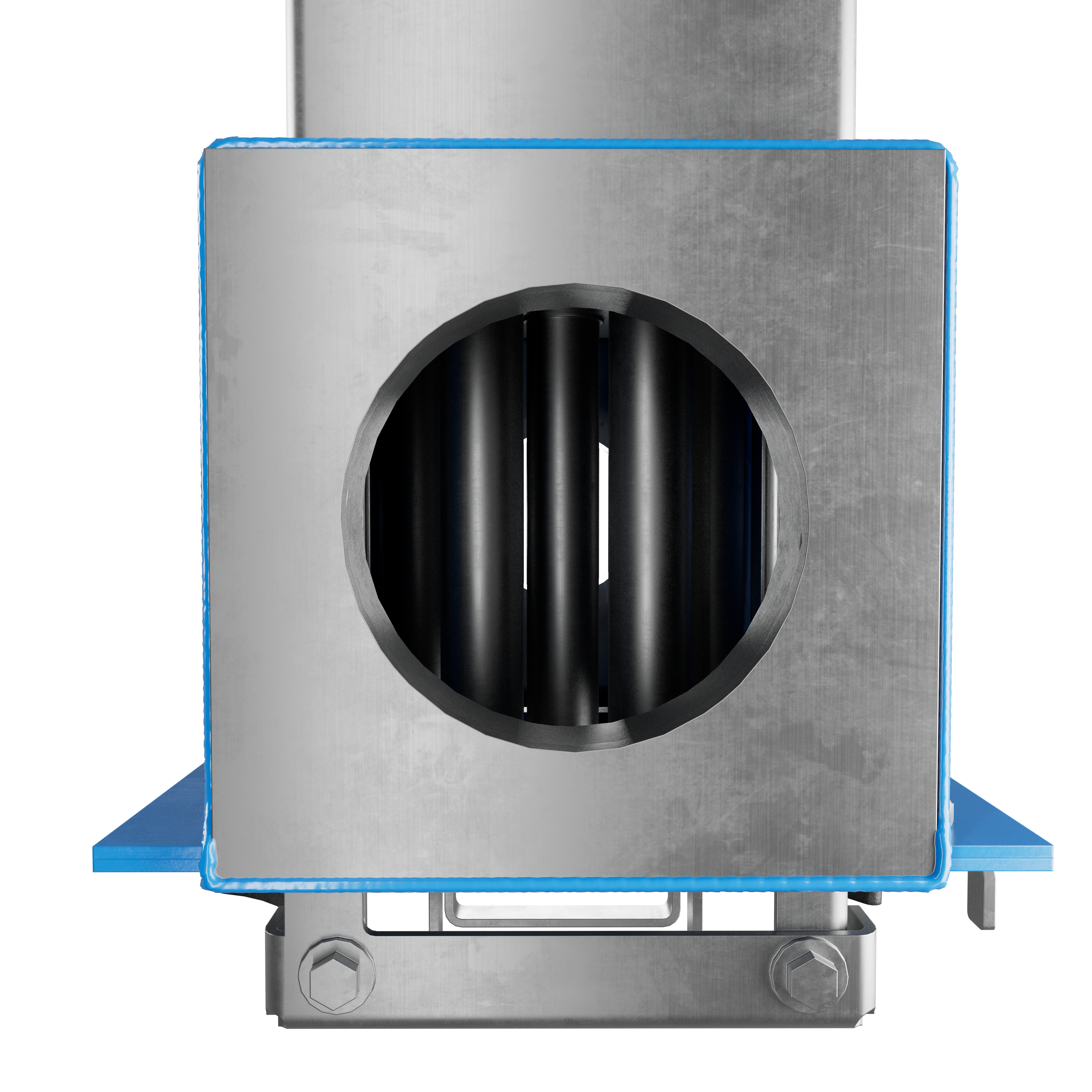

Bunting's Performer Series Pipeline Metal Detectors provide dependable contamination detection for liquids, pastes, and slurries. Designed for demanding applications in food, pharmaceutical, and industrial settings, these systems help maintain product quality and protect equipment.

These inline detectors feature hygienic stainless steel construction and a compact design that integrates easily into new or existing pipeline systems. User-friendly digital controls simplify operation and setup, while high-sensitivity detection ensures reliable performance in continuous processing environments. Built for washdown areas, each unit is designed for easy cleaning, routine maintenance, and minimal downtime.

Our pipeline metal detectors feature:

- Advanced detection technology for enhanced sensitivity

- Customizable designs for diverse pipeline setups and pressure needs

- Hygienic builds that meet stringent food safety standards

- Durable construction for reliable performance in tough environments

- Simple interfaces for easy use and upkeep

From the cost-effective Performer V Eco to the high-pressure Performer P Pro, Bunting offers a complete line of pipeline metal detection solutions. Our systems integrate smoothly into existing production, reducing downtime while improving product safety and quality.

Protect your brand, ensure consumer safety, and improve your production with Bunting's reliable Pipeline Metal Detectors. Contact us today to learn how our custom solutions can enhance your contamination control efforts.

Why Choose Bunting's Performer Metal Detectors?

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.