Industrial Conveyors

Engineered to Move. Built to Last.

Bunting designs and manufactures a full line of industrial-grade conveyors to move, feed, or discharge material in scrap handling, recycling, stamping, metalworking, and manufacturing applications. Whether you're feeding a shredder, transferring aluminum cans, or moving sharp steel parts, Bunting conveyors are engineered for reliability, durability, and magnetic precision.

Our conveyor systems include both magnetic and non-magnetic models. Each unit is built to customer specifications for seamless integration into existing workflows.

REQUEST QUOTE

Conveyor Types

Bunting offers a comprehensive range of conveyor solutions designed for specific industrial applications. Each type is engineered to handle unique material challenges while maintaining our standards for durability and performance.

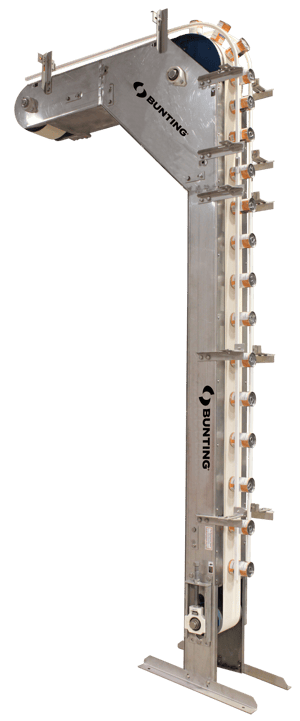

Feeder & Discharge Conveyors

Designed to feed material into shredders and remove it after processing, these conveyors handle heavy, abrasive, and jagged scrap with ease.

Key Uses:

- Feeding horizontal or vertical shredders

- Discharging processed ferrous and non-ferrous materials

- Integrating with separation systems

Features:

- Built for high-impact, high-volume scrap

- Optional magnetic pulleys for metal separation

- Available with infeed hoppers, armor plating, and containment covers

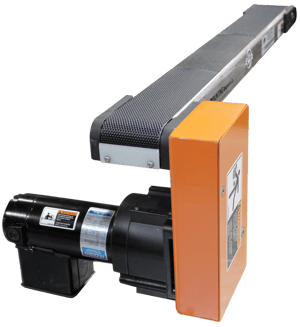

MagSlide® Magnetic Conveyors

Fully enclosed magnetic conveyors ideal for moving sharp, oily, or abrasive ferrous parts and chips with zero carryover and minimal maintenance.

Key Uses:

- Transporting stamping scrap, turnings, chips

- Clean and safe part movement under or around machinery

Features:

- No external moving parts

- Powerful ceramic or rare earth magnets

- Available in horizontal, incline, or Z-style layouts

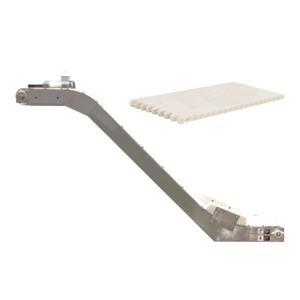

DragSlide™ Conveyors

Enclosed drag conveyors designed for safe and leak-proof movement of small or wet parts.

Key Uses:

- Collecting wet chips, grinding sludge, or scrap fines

- Situations requiring liquid containment

Features:

- UHMW drag flights inside fully enclosed channels

- Compact footprint with high torque drive

- Ideal for floor-level scrap removal

Magnetic Belt Conveyors

Ideal for elevating, holding, or controlling ferrous parts in machining or stamping operations.

Key Uses:

- Holding parts on incline or vertical surfaces

- Positioning ferrous components for inspection or processing

Features:

- Custom magnet layouts

- Stainless steel slider beds

- Available with cleated belts and guarding

Mattop Belted Conveyors

Durable, modular belted conveyors ideal for transporting lightweight cans, parts, and packages through production environments.

Key Uses:

- Moving cans, plastic bottles, or boxed product

- Lightweight product transfer in food or beverage environments

Features:

- Flat top plastic belting

- Washdown construction available

- Straight, curve, or Z configurations

Can Conveyors

Engineered specifically for moving two-piece aluminum or steel cans in decorator and printing operations.

Key Uses:

- Transferring cans between decorators, washers, and ovens

- Maintaining orientation and spacing

Features:

- Smooth, precise motion control

- Magnetic rail options for positive can retention

- Custom layouts for can line integration

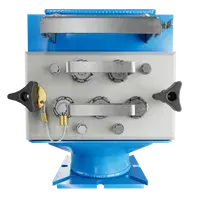

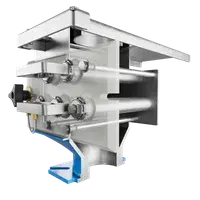

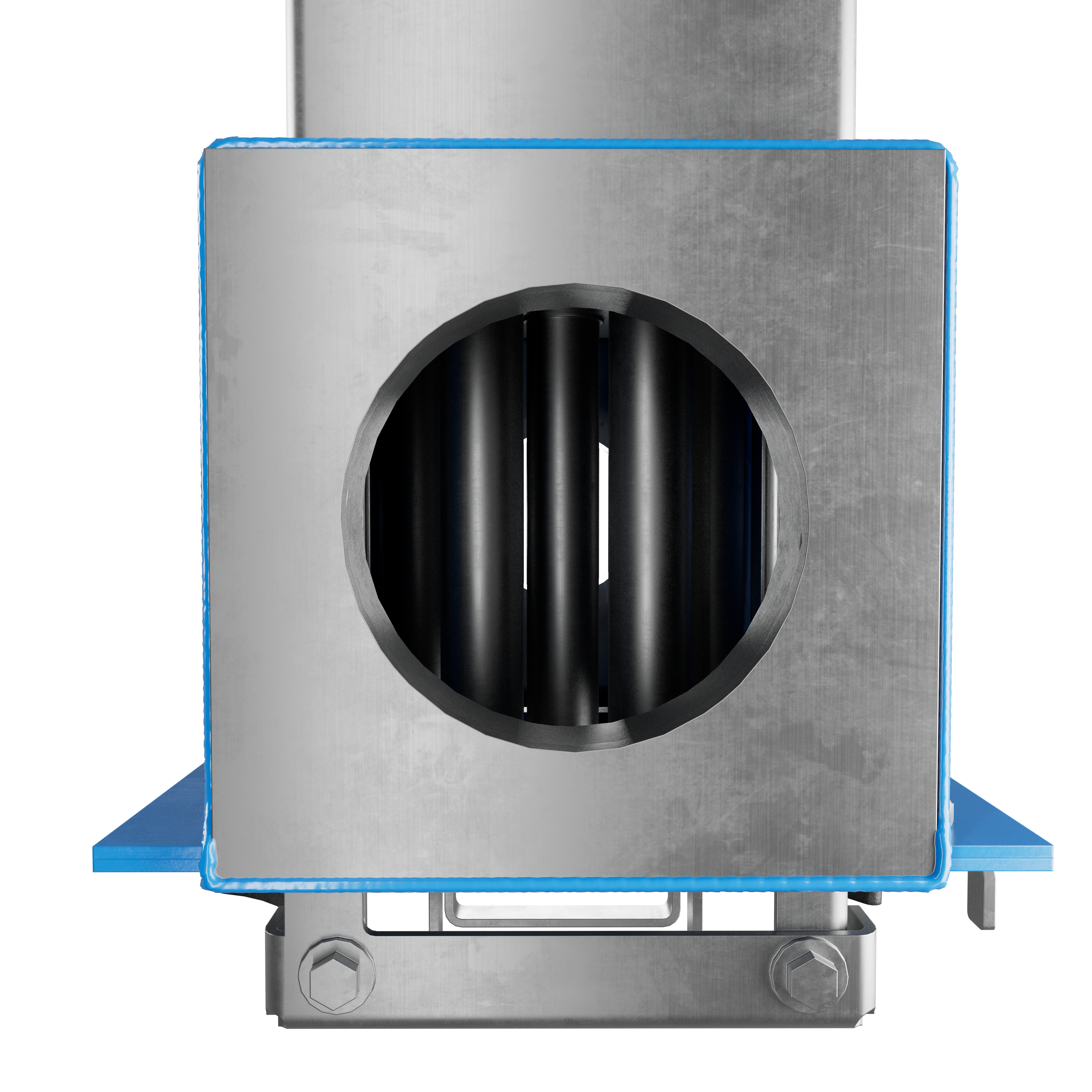

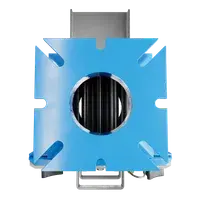

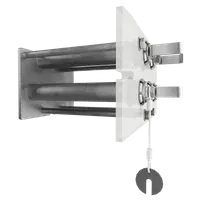

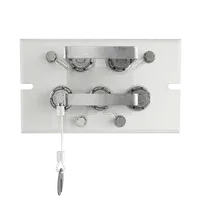

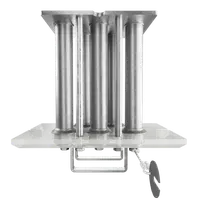

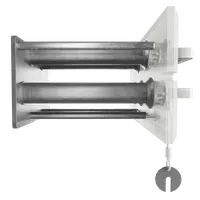

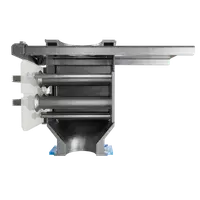

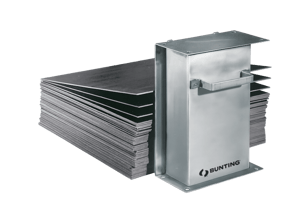

Magnetic Sheet Fanners

Automatically separate stacked steel sheets to speed up stamping line loading and reduce manual labor.

Key Uses:

- Separating oily or sticky sheets in press lines

- Improving operator safety and throughput

Features:

- Rare earth or ceramic options

- Adjustable fanning strength

- Pneumatic options available

Why Choose Bunting Conveyors?

Ready to Move Metal Smarter?

Contact our expert team today to design a Bunting conveyor system perfectly suited for your facility. Whether you're conveying cans, chips, or heavy scrap steel, we'll help you move it safely, efficiently, and with precision.